A kind of manufacture method of face mask

A manufacturing method and mask technology, applied in the field of mask manufacturing, can solve problems such as low production efficiency, achieve smooth and accurate delivery, ensure processing accuracy, and ensure welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

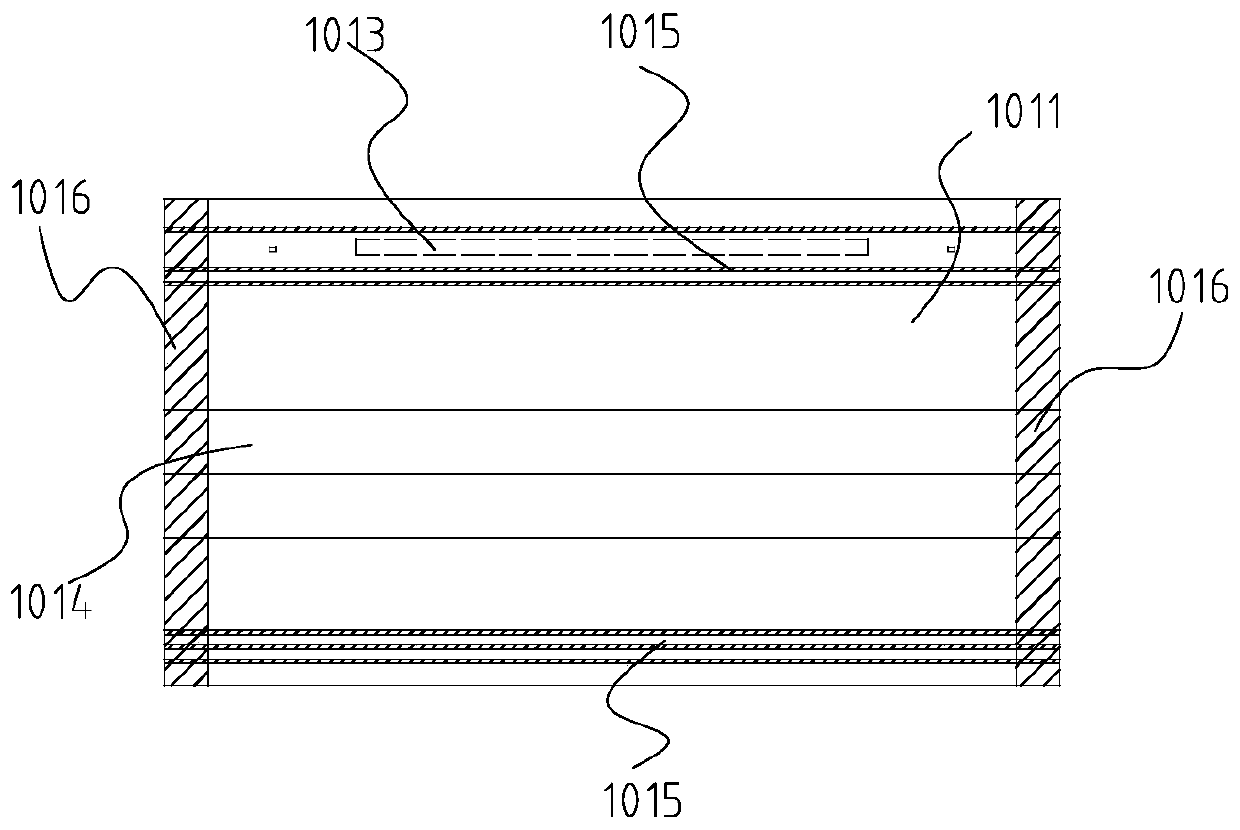

[0024] Embodiment, a kind of manufacturing method of mask, is used for continuous processing mask, as figure 1 , figure 2 As shown, the mask has a longitudinal direction y and a transverse direction x, and includes a mask main body 101 covering the wearer's nose and mouth when worn, and an elastic ear piece 102 combined with the mask main body 101 by ultrasonic welding or thermal fusion.

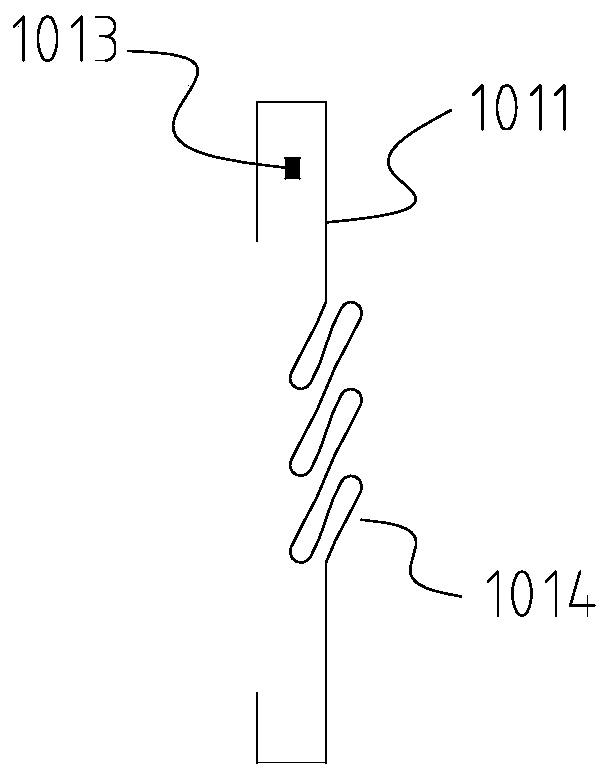

[0025] Wherein, the mask main body 101 includes an outer layer sheet 1011 , an inner layer sheet 1012 , and a filter sheet arranged between the outer layer sheet 1011 and the inner layer sheet 1012 . The mask main body 101 is extended and folded in the transverse direction to form a plurality of pleats 1014 , and the pleats 1014 can be deployed longitudinally in the middle area of the mask main body 101 . The size of the outer layer sheet 1011, the inner layer sheet 1012 and the filter sheet does not require to be identical, and the mask main body sheet forms a transverse seal 1015 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com