Lithium ion battery high-nickel positive electrode material and preparation process thereof

A technology for lithium-ion batteries and cathode materials, which is applied in the field of high-nickel cathode materials for lithium-ion batteries and its preparation process, can solve the problems of long dissolution time of polydene tetrafluoride, improve compaction density and electrical conductivity, and increase compactness. degree, the effect of capacity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] High nickel positive electrode A: D10: ≥5 μm, D50: 9-15 μm, D90: ≤30 μm.

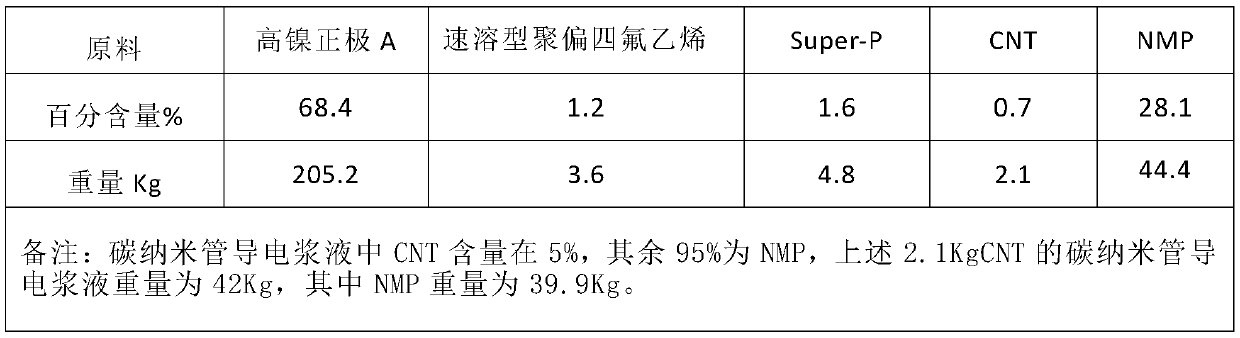

[0034] 1. Prepare raw materials according to the percentage and weight in the following table to make high-nickel cathode slurry for lithium-ion batteries:

[0035]

[0036] 2. Preparation of cathode slurry

[0037] 2.1 Glue preparation: gradually disperse 4.2Kg of instant polyvinylidene fluoride into the NMP being stirred in a double planetary stirring pot (produced by Guangzhou Hongyun Mixing Equipment Co., Ltd.) for mixing, and prepare a glue solution with a mass fraction of 10.7%. Do not turn on the circulating water, stir at the speed of revolution 15rpm, disperse 1500rpm, the stirring time is 60min; after stirring for 10min, recover the materials around the stirring paddle in time, and keep the vacuum <-0.08MPa during the stirring process;

[0038] 2.2 Premix: Add 205.2Kg of high-nickel positive electrode and 4.8Kg of conductive carbon black into another stirring pot, stir thoroughly fo...

Embodiment 2

[0048] High nickel positive electrode A: D10: ≥5 μm, D50: 11-14 μm, D90: ≤30 μm.

[0049] 1. Prepare raw materials according to the percentage and weight in the following table to make high-nickel cathode slurry for lithium-ion batteries:

[0050]

[0051] 2. Preparation of cathode slurry

[0052] 2.1 Glue preparation: Gradually disperse 3.3Kg of instant polyvinylidene fluoride into the stirring NMP in a double planetary stirring pot (Guangzhou Hongyun Mixing Equipment Co., Ltd.) Turn on the circulating water, stir at the speed of revolution 15rpm, disperse 1500rpm, the stirring time is 60min; after stirring for 10min, recover the materials around the stirring paddle in time, and keep the vacuum <-0.08MPa during the stirring process;

[0053] 2.2 Premix: Add 213Kg of high-nickel positive electrode and 2.1Kg of conductive carbon black into another stirring pot, stir thoroughly for 10min at a speed of 15rpm in revolution and 500rpm in dispersion, and then add 25Kg of glue an...

Embodiment 3

[0063] High nickel positive electrode A: D10: ≥5 μm, D50: 10-14 μm, D90: ≤30 μm.

[0064] 1. Prepare raw materials according to the percentage and weight in the following table to make high-nickel cathode slurry for lithium-ion batteries:

[0065]

[0066]

[0067] 2. Preparation of cathode slurry

[0068] 2.1 Glue preparation: Gradually disperse 3.3Kg of instant polyvinylidene fluoride into the stirring NMP in a double planetary stirring pot (Guangzhou Hongyun Mixing Equipment Co., Ltd.) Turn on the circulating water, stir at the speed of revolution 15rpm, disperse 1500rpm, the stirring time is 60min; after stirring for 10min, recover the materials around the stirring paddle in time, and keep the vacuum <-0.08MPa during the stirring process;

[0069] 2.2 Premix: Add 198.6Kg high-nickel positive electrode and 3.0Kg conductive carbon black into another stirring pot, stir thoroughly for 10min at a speed of 15rpm in revolution and 500rpm in dispersion, and then add 25Kg of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com