X-ray flaw detector verification platform and measurement method

A radiographic flaw detection and X-ray technology, which is applied in the field of X-ray flaw detector verification platform, can solve the problems of excessive radiation leakage, radiation beam deviation, poor irradiation sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

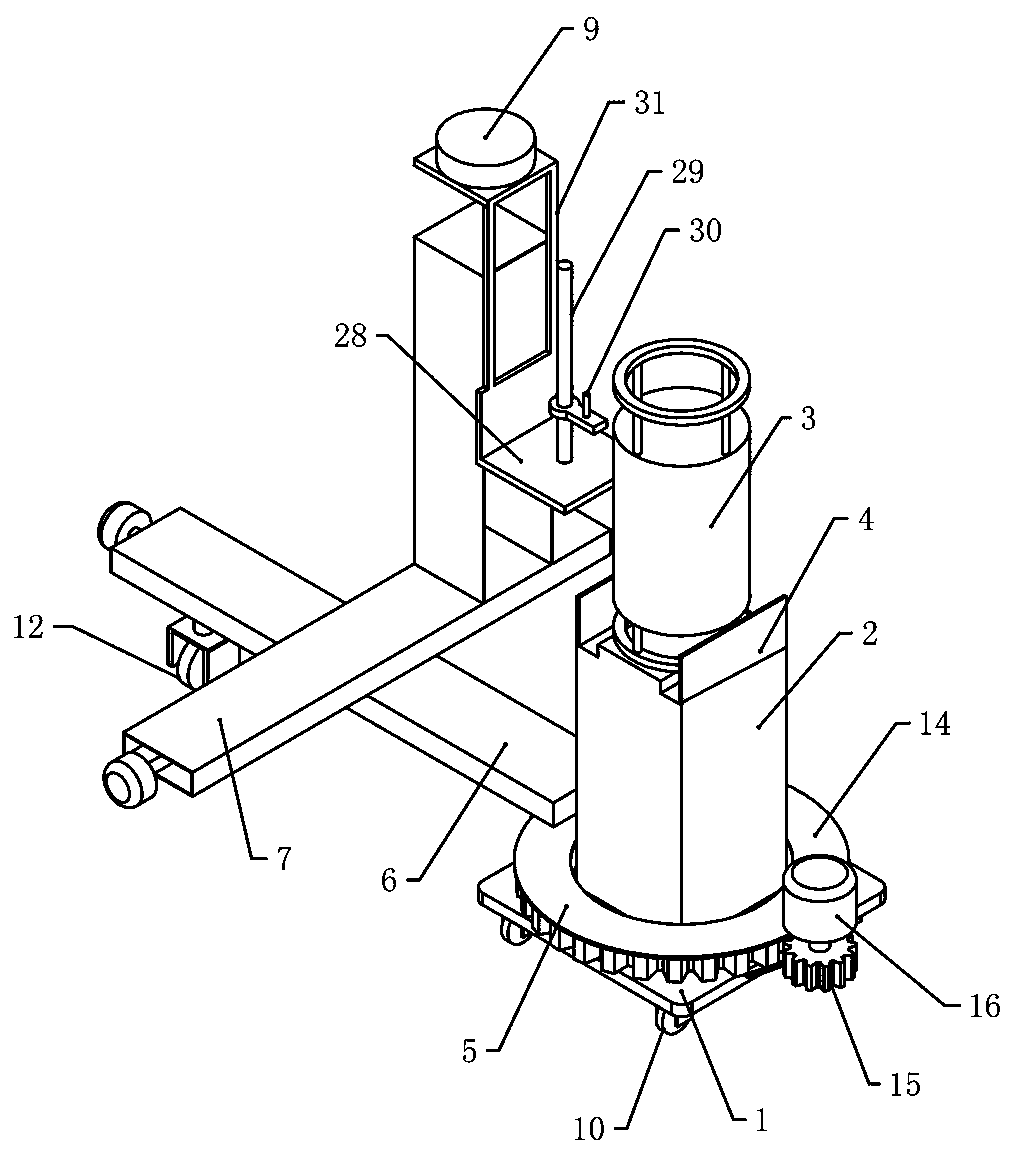

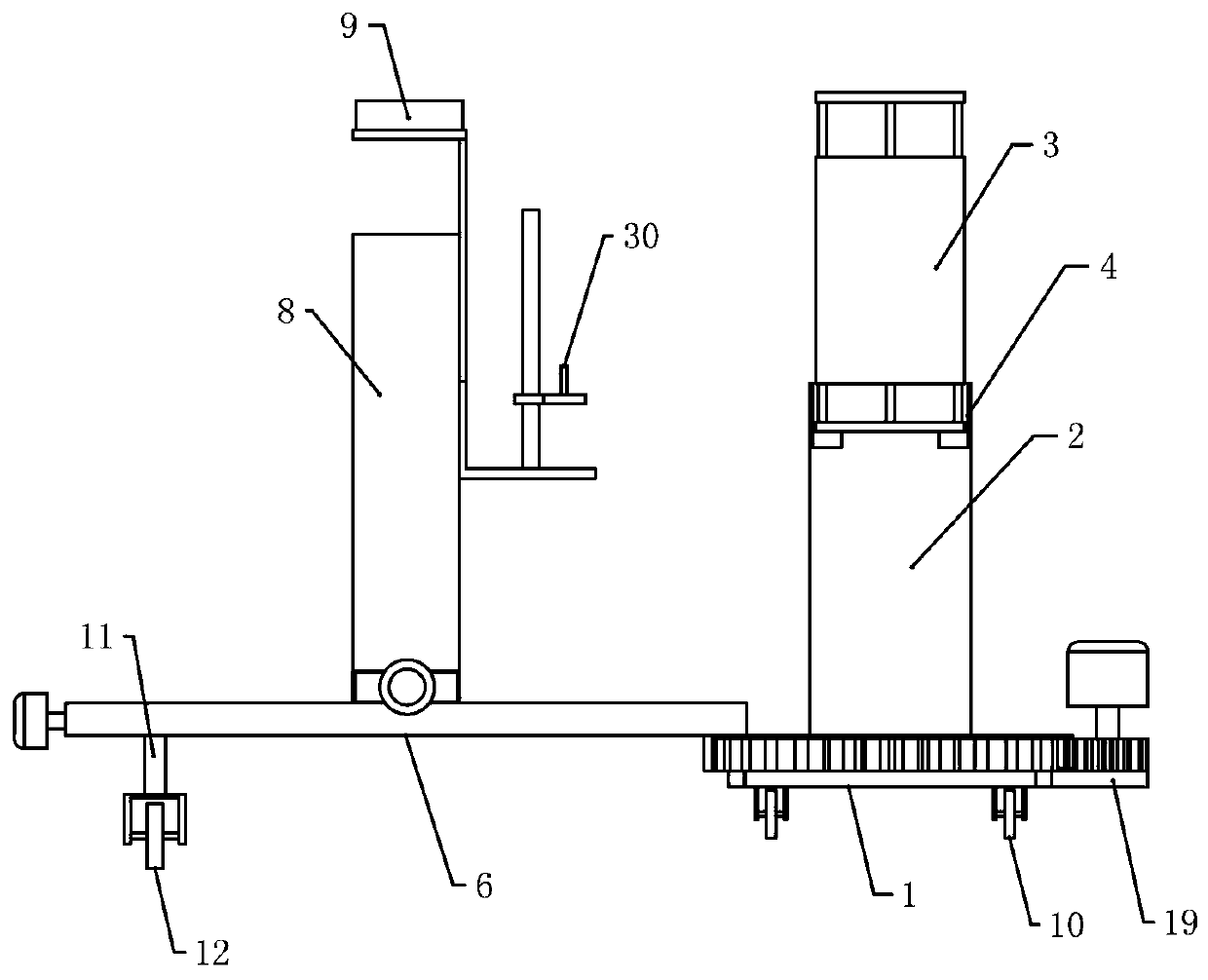

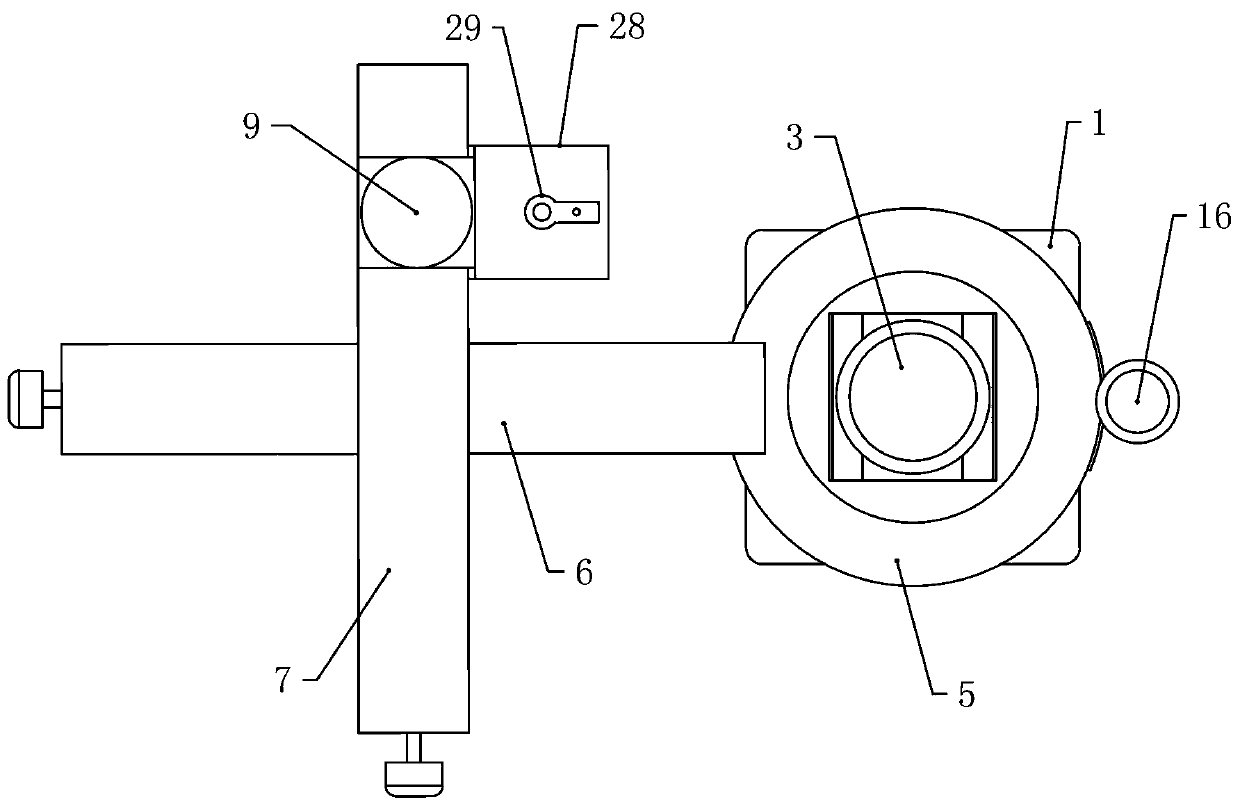

[0062] Embodiment 1, a verification platform for an X-ray flaw detector, including a central stand 1, the central stand 1 is a square, with chamfers at the four corners, a placing platform 2 is fixed on the central stand 1, and the placing platform 2 is vertical The cube of X-ray flaw detection machine 3 is fixedly installed above the placement platform 2, and the window of X-ray flaw detection machine 3 is equipped with a shielding cover 4, and 5 rotating platforms are installed on the central stand 1, and the rotating platform 5 can rotate. The rotating platform 5 is circular, and the center is hollow. The rotating platform 5 is set on the outside of the placing platform 2. When the rotating platform 5 rotates, the placing platform 2 does not rotate. The upper surface of the rotating platform 5 is equipped with a radial moving platform 6, following The rotating platform 5 rotates together, and the horizontal moving platform 7 is installed on the radial moving platform 6, and ...

Embodiment 2

[0063] Embodiment 2, on the basis of Embodiment 1, four first universal wheels 10 are installed below the central stand 1 to facilitate the movement of the central stand 1. The first universal wheels 10 have a brake function. The outer end of the radially movable platform 6 is connected to the second universal wheel 12 through the fixed rod 11. The second universal wheel 12 has a braking function, and the second universal wheel 12 can rotate around the placement platform 2.

Embodiment 3

[0064] Embodiment 3, on the basis of Embodiment 1, the rotating platform 5 includes a large gear 13, a gear cover 14 is installed on the outside of the large gear 13, and a pinion 15 is meshed on the side of the large gear 13, and the pinion 15 is connected to a second gear through a rotating shaft. A stepping motor 16, the bottom of the bull gear 13 rotates and is installed on the central stand 1, the first stepping motor 16 starts to drive the pinion 15 to rotate, the pinion 15 meshes with the bull gear 13 to rotate, and the bull gear 13 drives the gear cover 14 Rotating, the gear cover 14 drives the radially moving platform 6 to rotate around the placement platform 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com