Device and method for measuring diameter of dense pipe bundle and thickness of oxide film on site

A thickness measurement and oxide film technology, which is used in nuclear reactor monitoring, reactors, nuclear power generation, etc., can solve the problems of large measurement errors, the diameter of dense tube bundles and the thickness of oxide films are difficult to measure at any position in the whole stroke, to achieve detection safety, Reliable measurement results and the effect of preventing radiation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

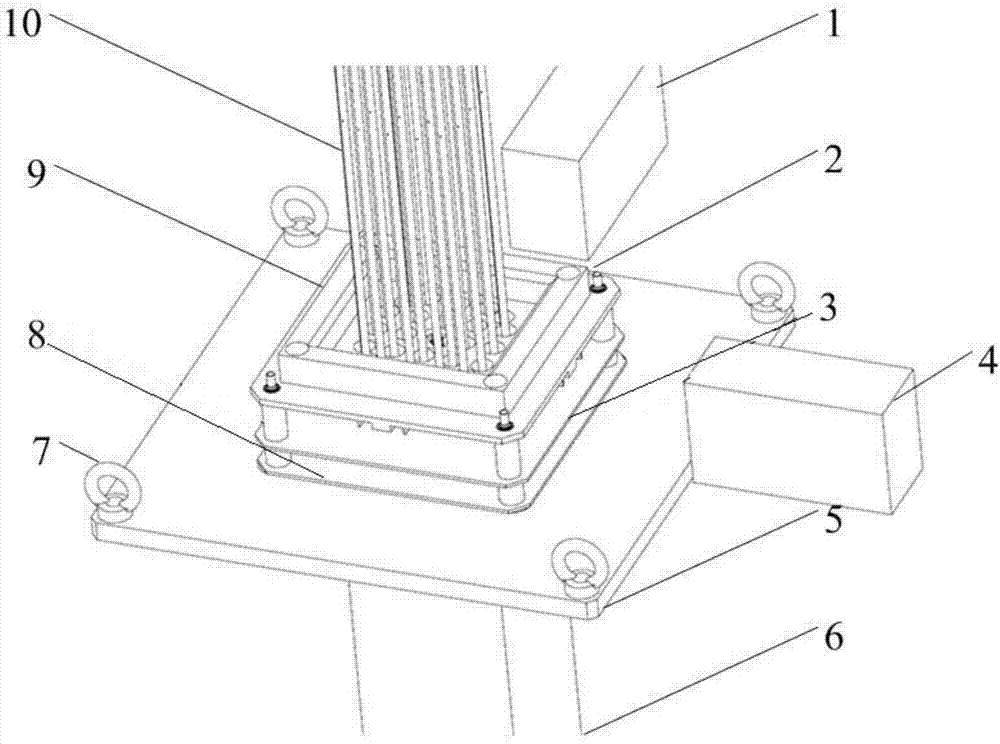

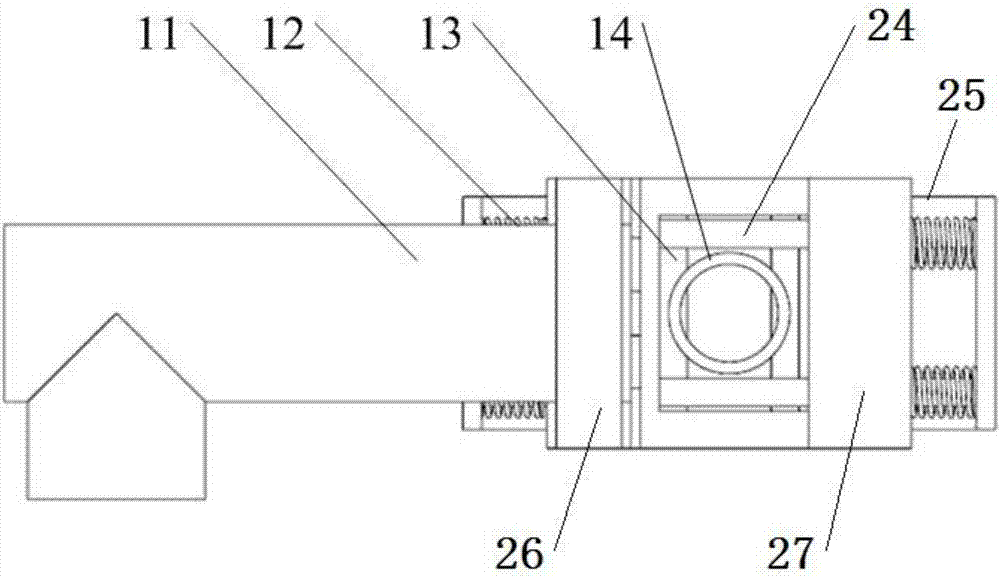

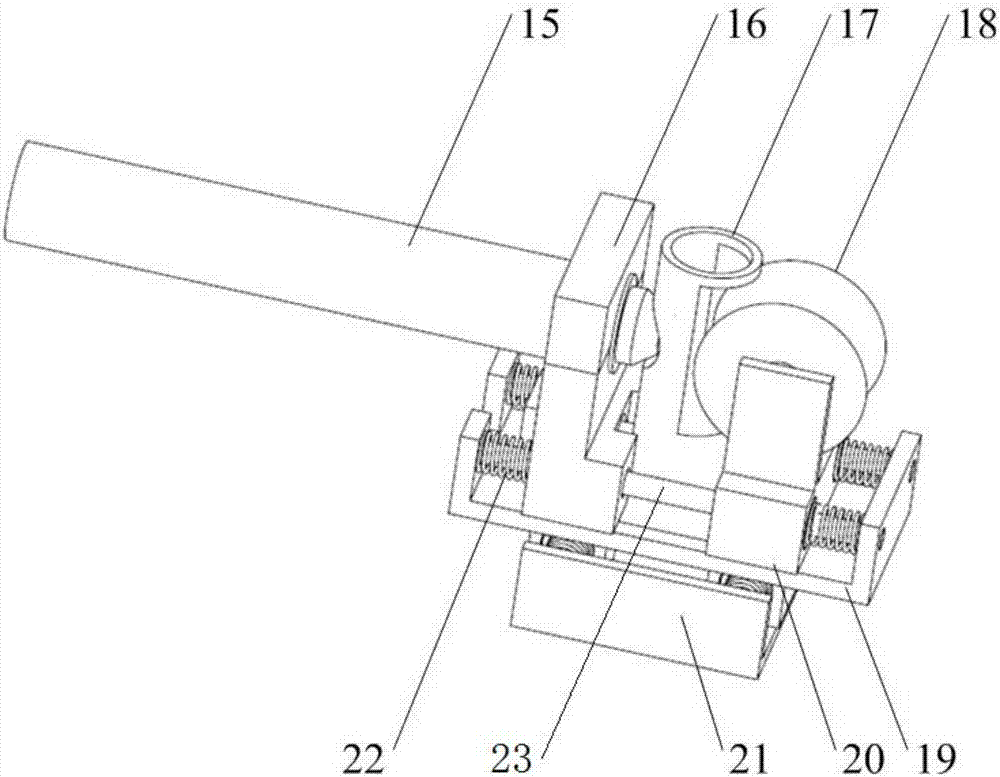

[0034] Such as Figure 1 to Figure 5 As shown, the present invention relates to a device and method for measuring the diameter and oxide film thickness of highly radioactive dense sample tubes on site after nuclear power plants and research reactors are irradiated. The irradiation sample tube bundle is composed of 16 irradiation sample tubes, and the layout corresponds to Figure 4 There are 16 locations on the periphery. In this embodiment, the rod diameter and oxide film thickness are measured for 16 irradiated sample tubes. Its hardware structure includes 8 rod diameter measuring units and 8 oxide film thickness measuring units installed on the measuring bench, which correspond to the structure of the irradiated tube bundle and can be adjusted according to the structure of the irradiated tube bundle. The rod diameter measuring unit are all set in the same horizontal plane, the oxide film thickness measurement units are all set in the same horizontal plane, the oxide film th...

Embodiment 2

[0047] Such as Figure 1 to Figure 5 As shown, this embodiment measures the rod diameter and oxide film thickness for 16 irradiated sample tubes, and the A1B1, A2B2, A3B3, and A4B4 measurement units serve as backups for each other. If a measurement unit fails, the backup measurement can be used through the rotating assembly The unit is detected, which improves the measurement efficiency. That is, when a certain measurement unit breaks down in Embodiment 1, the measurement is implemented as follows:

[0048] Step 1. Same as in Embodiment 1, lift the detection device into the spent fuel pool through four lifting lugs 7, insert the positioning tube 6 into the hole of the spent fuel storage grid assembly, and place the main support plate on the spent fuel storage grid.

[0049] Step 2, the same as in Example 1, insert a standard rod in advance, measure the value through the rod diameter measurement unit and the oxide film thickness measurement unit, as a standard value, use the nuc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com