Automatic detection device for honeycomb ceramic and detection method of device

A honeycomb ceramics, automatic detection technology, applied in the direction of automatic feeding/discharging of weighing equipment, measuring devices, instruments, etc., can solve the problems of inability to meet the needs of modern production, the detection quality cannot be guaranteed, and the manual detection steps are complicated. Achieve the effect of compact structure, improved production efficiency and product quality, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

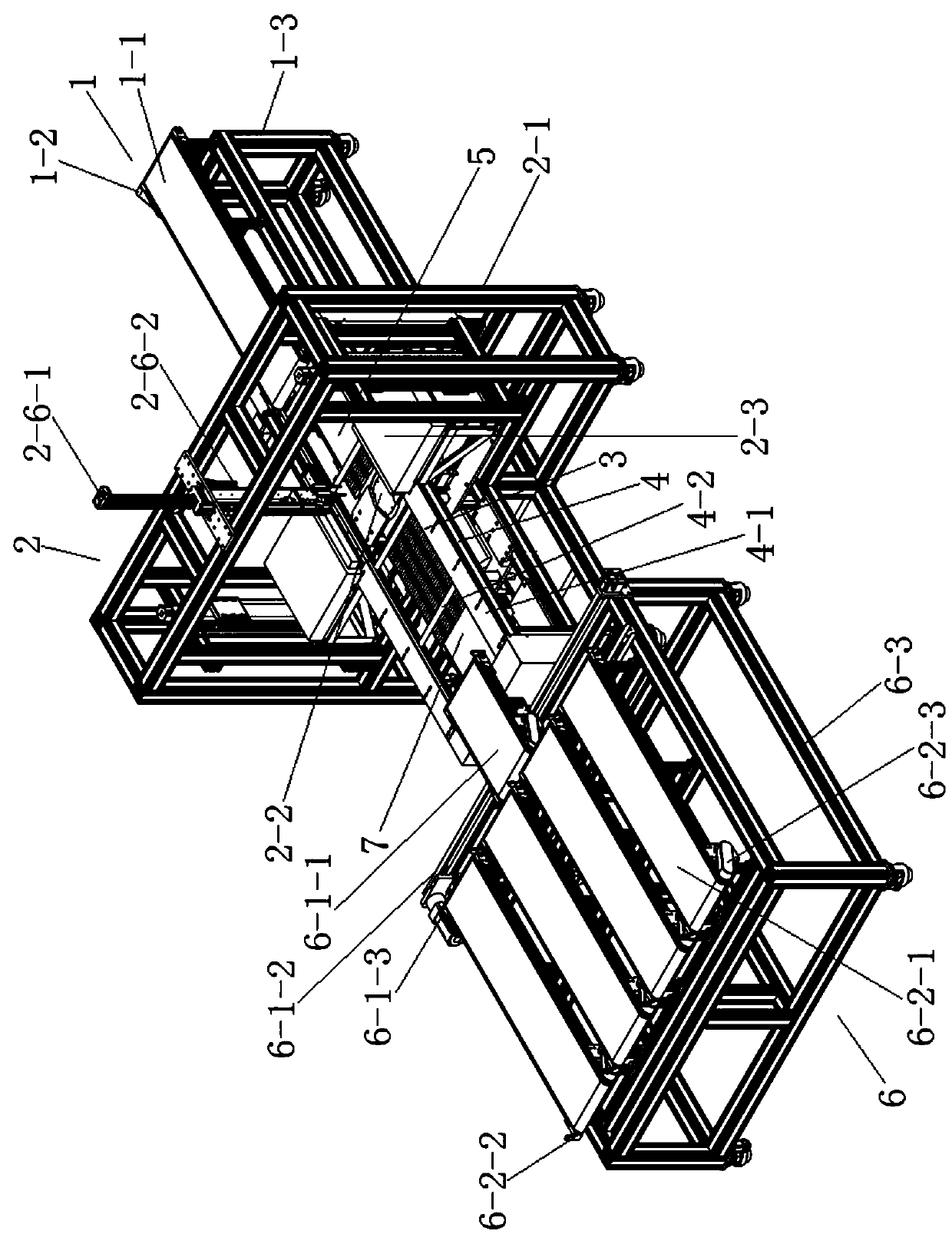

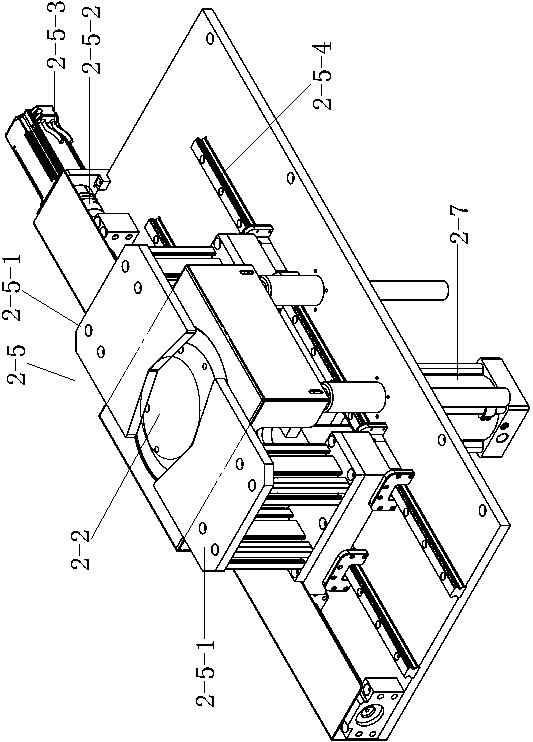

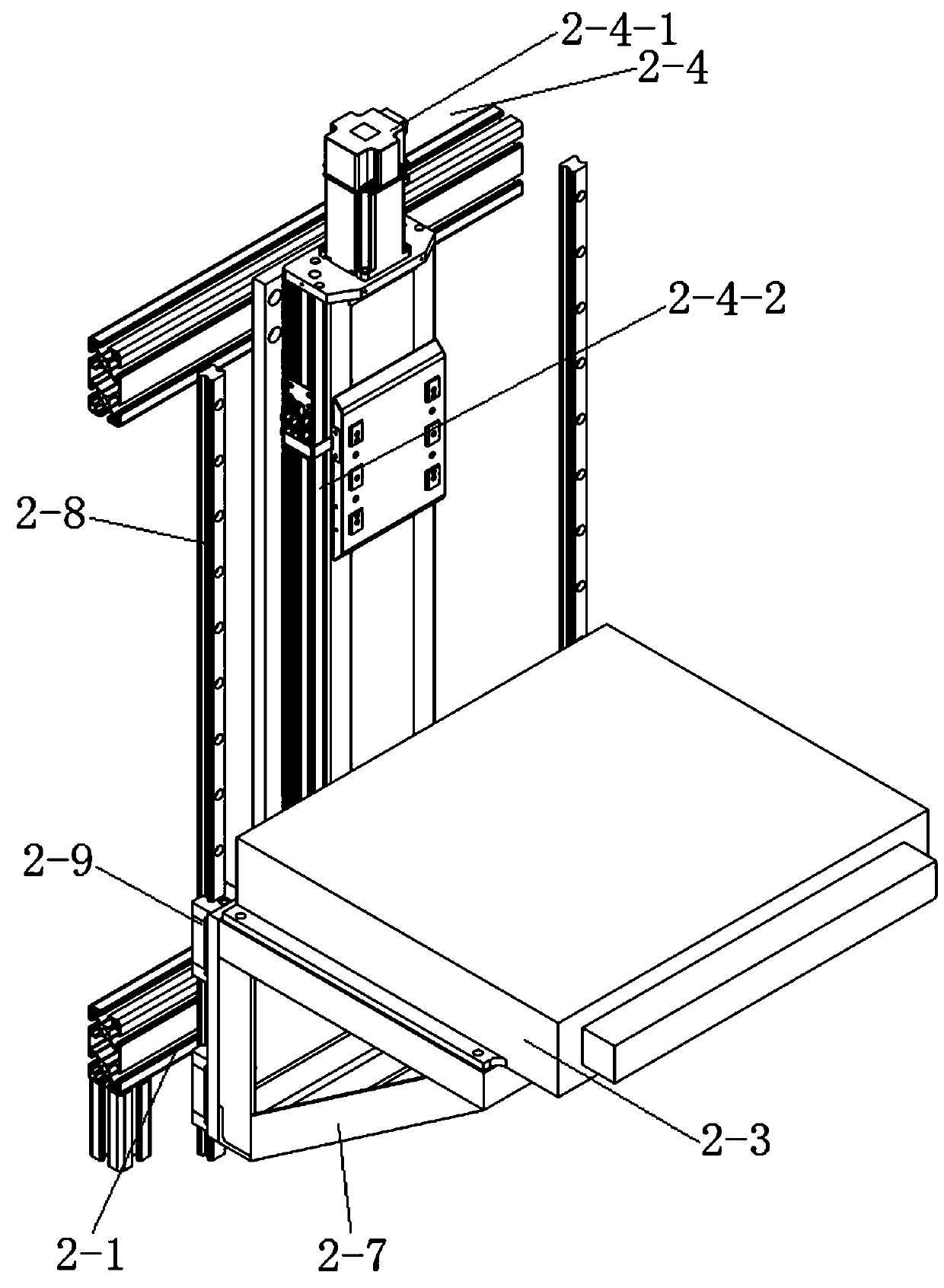

[0052] Refer to attached Figure 1-5 The honeycomb ceramics automatic detection equipment includes honeycomb ceramics feeding conveyor belt device 1, lifting conveyor belt mechanism 1, honeycomb ceramics outer dimension parallelism and verticality detection device 2, weighing mechanism 3, honeycomb ceramics detection transmission mechanism 4, lifting conveyor belt mechanism 2 7 And automatic sorting device 6.

[0053] The honeycomb ceramic outer dimension parallelism perpendicularity detection device 2 is arranged on the frame 2-1, the honeycomb ceramic feeding conveyor belt device 1 is arranged at the rear part of the honeycomb ceramic outer dimension parallelism perpendicularity detection device 2, and the honeycomb ceramic feeding conveyor belt device 1 and the parallelism and perpendicularity detection device 2 of the outer dimension of the honeycomb ceramics are provided with a lifting conveyor mechanism 17, and the weighing mechanism 3 is arranged at the front of the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com