Antibacterial polyester staple fiber and processing equipment thereof

A technology of polyester staple fiber and antibacterial fiber, applied in the field of fiber structure, can solve the problems of poor antibacterial effect and low structural strength of polyester staple fiber, and achieve the effects of stable properties, good stability and not easy to rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

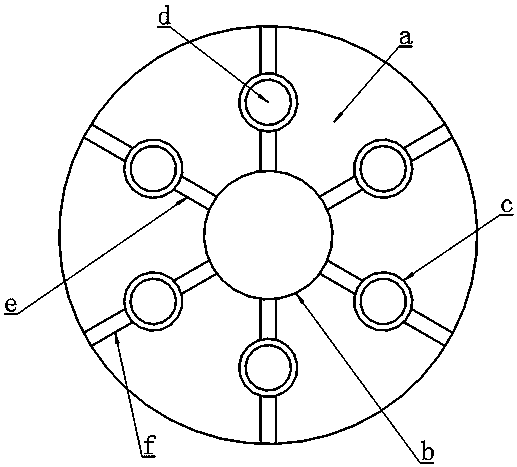

[0024] Example: as attached figure 1 As shown, an antibacterial polyester staple fiber includes a polyester staple fiber main body a, the polyester staple fiber main body a is cylindrical, and a ventilation hole b is provided at the center of the circle center of the polyester staple fiber main body a, and the polyester staple fiber main body a The short fiber main body a is provided with an installation channel c, the installation channel c is provided with an antibacterial fiber d, and the installation channel c is provided with an inner channel e that communicates with the ventilation channel b inwardly, and an outer channel e that penetrates inwardly. Channel f.

[0025] In this embodiment, the inner channel e and the outer channel f are arranged at intervals for ventilation and dehumidification, and the ventilation channel b is used for storing hot air to basically keep warm.

[0026] The inner diameter of the ventilation channel b is 20-35% of the diameter of the polyes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com