Gas protection method applied to pouring process of middle column pipe and device thereof

A gas protection device and gas protection technology are applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc., which can solve problems such as trouble, steelmaking quality decline, and material ejection to the outside of the shell, so as to improve removal efficiency, Promote the effect of collision growth and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

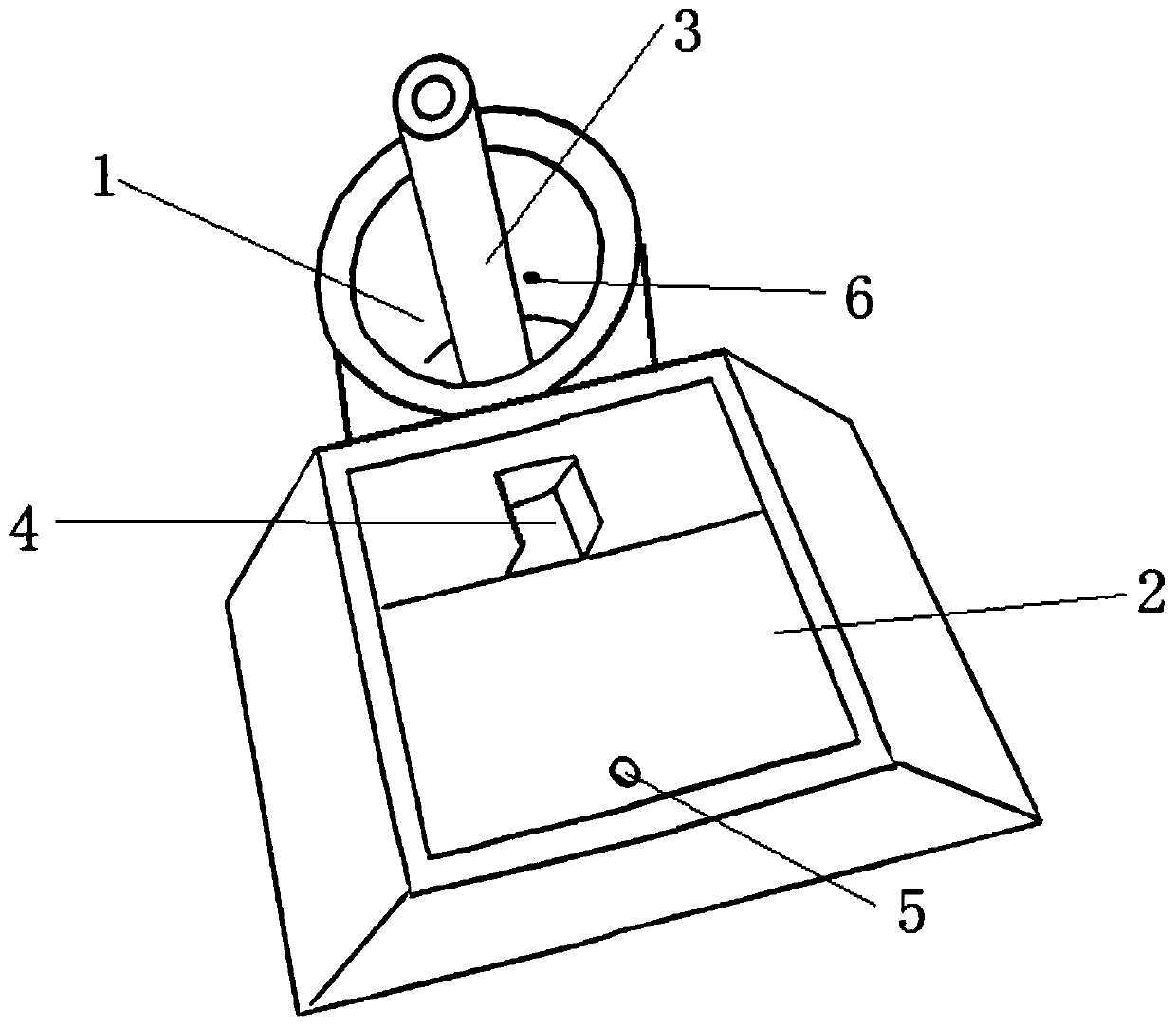

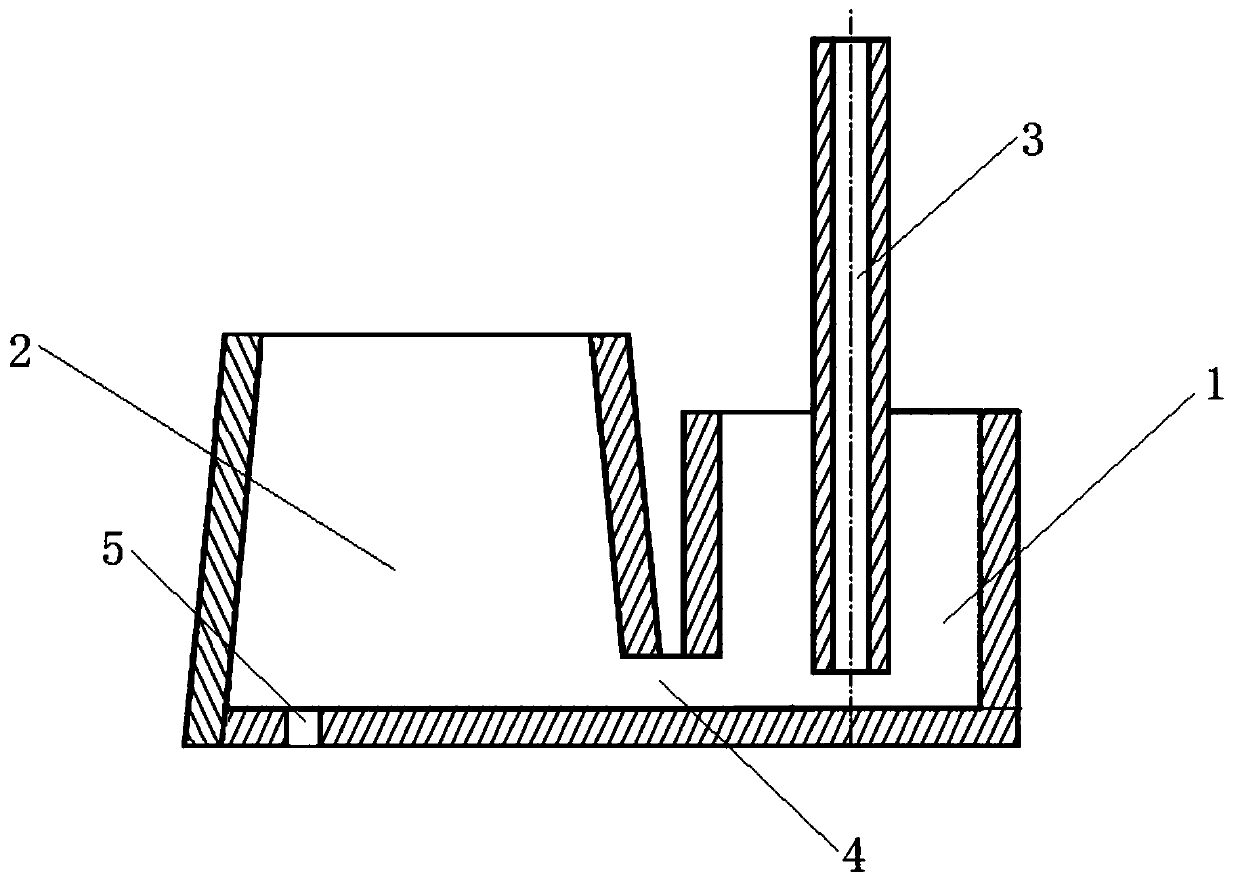

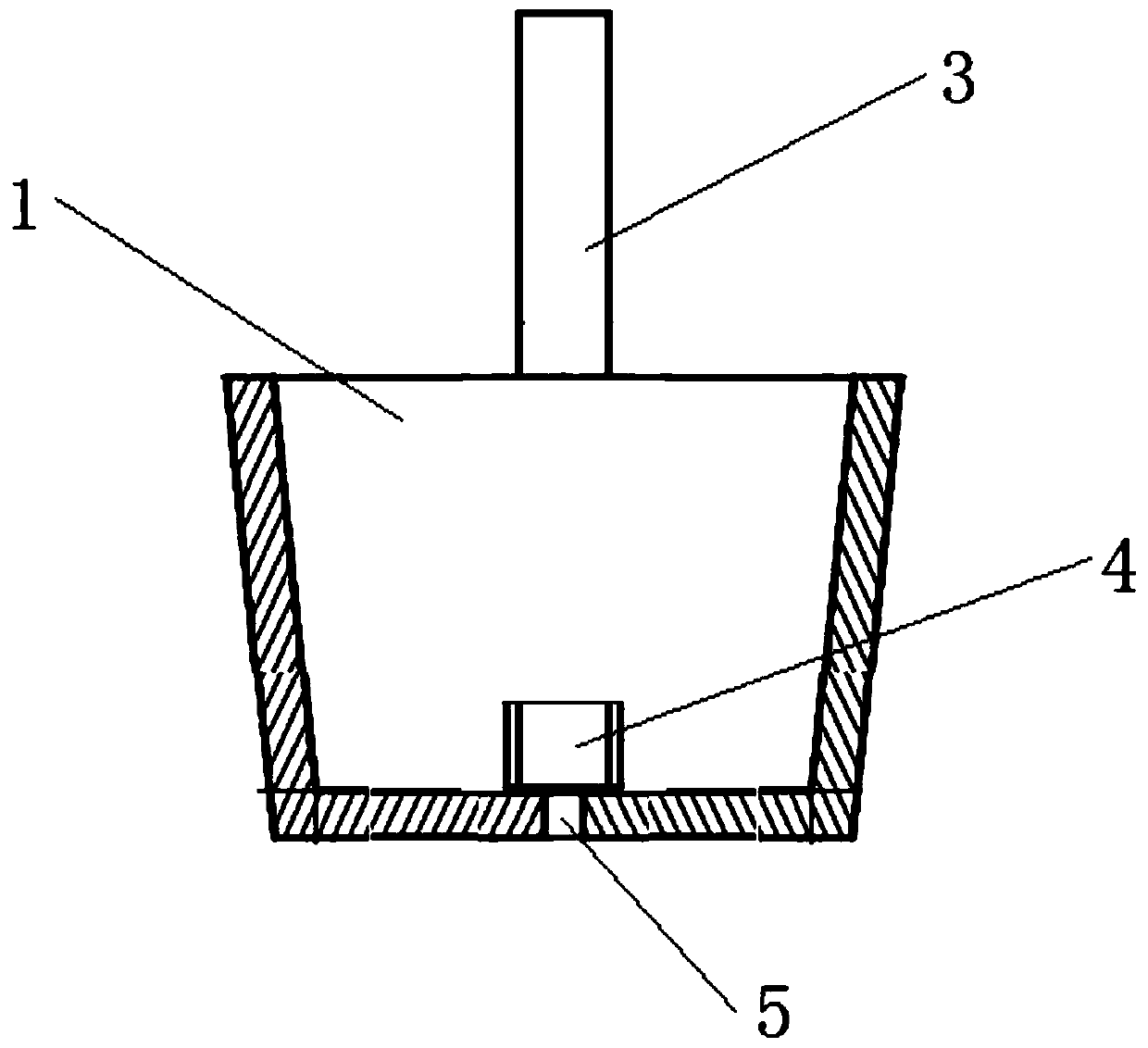

[0017] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

[0018] The present invention is applied to the gas protection method of the middle column pipe pouring process, comprising the following steps:

[0019] Step 1: When the molten steel has not flowed into the ladle 1, the inert gas is introduced into the ladle 1 through the vent 4 at the bottom of the ladle 1 until all the molten steel flows into the ladle 1, and the blowing direction of the inert gas is towards the direction of the swirling flow of the molten steel Horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com