A device and method for rotating molten steel in a tundish

A technology of rotating device and tundish, which is applied in metal processing equipment, manufacturing tools, casting melt containers, etc., can solve the problems of large structural transformation, complicated operation and power consumption of the tundish, and achieves the promotion of collision growth and strengthening. Rotation, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

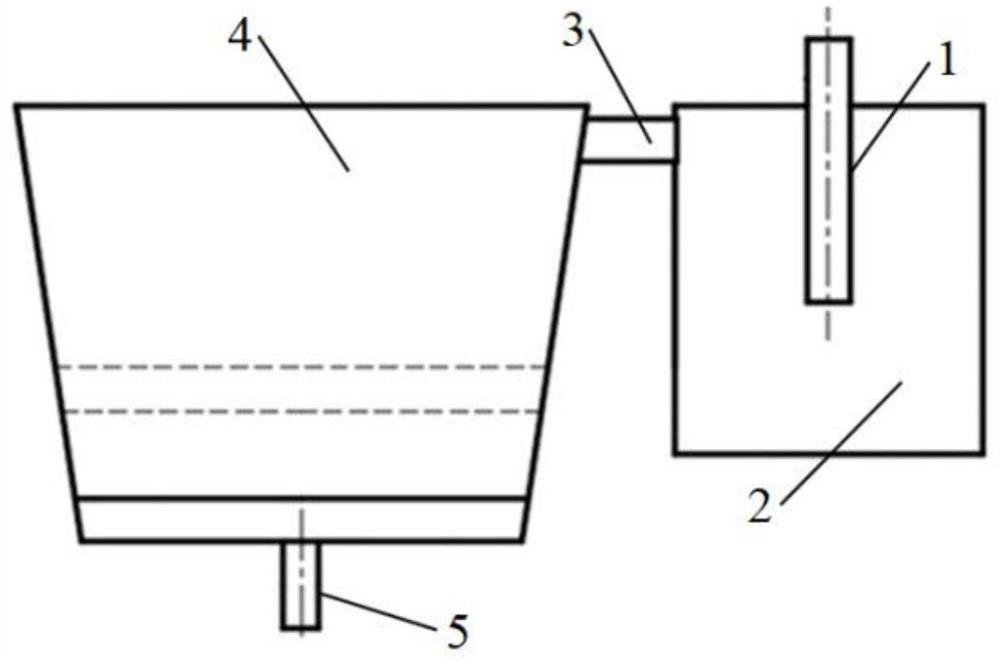

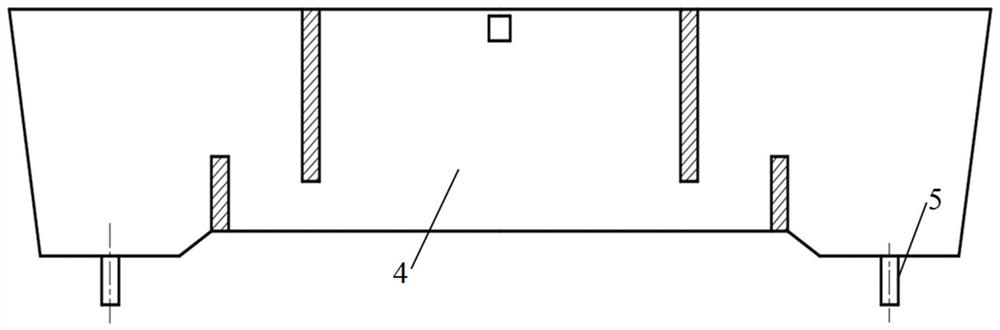

[0045] Such as Figure 7-8 As shown, the height of the molten steel surface 8 of the external tundish swirl chamber 2 in the molten steel rotating device of this embodiment is 800 mm, and the inner diameter of the external tundish swirl chamber 2 is 700 mm; the swirl flow below the ladle shroud 1 The generating device 9 is a cube with a height of 200mm. There are 2 swirl outlets 10, which are linear with a horizontal angle θ of 45°; week. The average diameter of inclusions is increased from 3.90 μm to 4.13 μm by using the molten steel rotating device provided in this embodiment.

Embodiment 2

[0047] Such as Figure 9-11 As shown, the height of the molten steel surface 8 of the external tundish swirl chamber 2 in the molten steel rotating device of this embodiment is 800 mm, and the inner diameter of the external tundish swirl chamber 2 is 700 mm; the swirl flow below the ladle shroud 1 The generating device 9 is a cube with a height of 200 mm. There are 4 swirl outlets 10, which are linear with a horizontal angle θ of 60°; week. The average diameter of the inclusions is increased from 3.90 μm to 4.19 μm by using the molten steel rotating device provided in this embodiment.

Embodiment 3

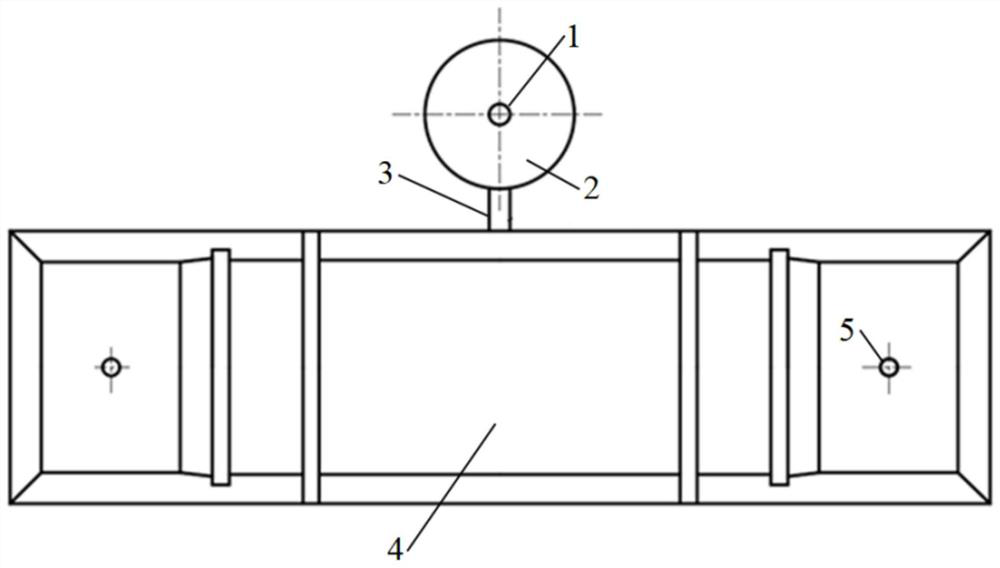

[0049] Such as Figure 12 As shown, the height of the molten steel surface 8 of the external tundish swirl chamber 2 in the molten steel rotating device of this embodiment is 800 mm, and the inner diameter of the external tundish swirl chamber 2 is 700 mm; the swirl flow below the ladle shroud 1 The generating device 9 is a cylinder with a height of 150mm, and there are 6 swirl outlets 10, which are arc-shaped; the swirl guide rails 6 have a rotation height of 500mm, and the number is 4, each of which rotates 2 times. The average diameter of the inclusions is increased from 3.90 μm to 4.23 μm by using the molten steel rotating device provided in this embodiment.

[0050] The rotating molten steel promotes the centripetal movement of inclusions while uniform composition and temperature, which is beneficial to the collision aggregation of inclusions, and improves the removal efficiency of inclusions and the cleanliness of molten steel. The method for swirling molten steel descr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com