Hard water resistant vegetable oil emulsified complexing agent and preparation thereof

A technology of vegetable oil and compounding agent, which is applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problems of difficulty in achieving stability and emulsified oil in a stable emulsified state, and achieve long service life, good anti-corrosion effect, Superior hard water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

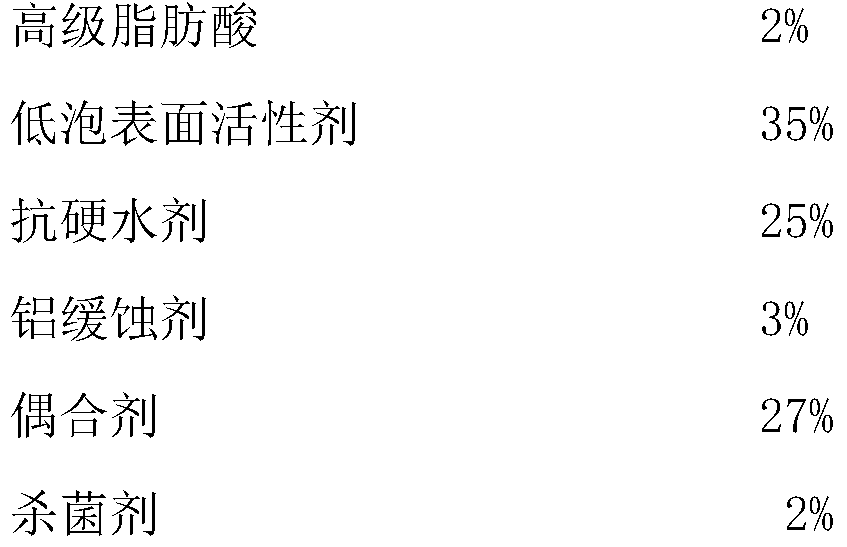

[0034] A kind of anti-hard water type vegetable oil emulsifying compound, consists of the following components by weight percentage:

[0035]

[0036]

[0037] Described preparation method comprises the steps:

[0038] 1) Add monoethanolamine, triethanolamine, and higher fatty acids into the reaction tank in proportion, and stir for about 30 minutes at 50-60°C;

[0039] 2) Add low-foaming surfactant, anti-hard water agent, aluminum corrosion inhibitor, and coupling agent to the mixture in step 1 in proportion by mass percentage, and stir at 40-50°C for 20 minutes;

[0040] 3) Add the bactericide to the mixture obtained in step 2 at 40° C., and stir for 20-25 minutes.

Embodiment 2

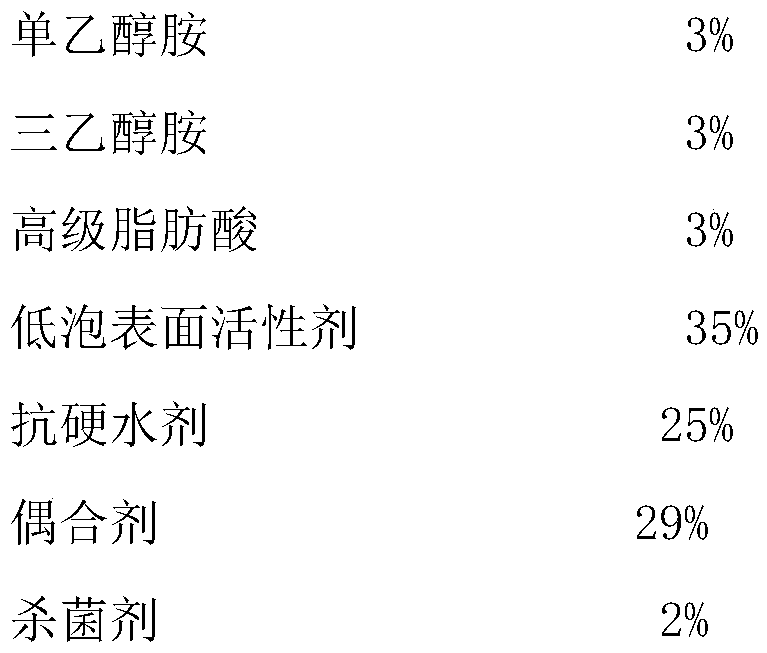

[0042] A kind of anti-hard water type vegetable oil emulsifying compound, consists of the following components by weight percentage:

[0043]

[0044] Described preparation method comprises the steps:

[0045] 1) Add monoethanolamine, triethanolamine, and higher fatty acids into the reaction tank in proportion, and stir for about 30 minutes at 50-60°C;

[0046] 2) Add low-foaming surfactant, anti-hard water agent, and coupling agent to the mixture in step 1 in proportion by mass percentage, and stir at 40-50°C for 20 minutes;

[0047] 3) Cool to 40°C, add the bactericide to the mixture obtained in step 2, and stir at 40°C for 20-25 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com