Corundum mullite multiphase gradient material for heat recovery coke oven door

A gradient material, mullite technology, applied in coking oven doors/closures, coking ovens, heating of coking ovens, etc., can solve problems such as uneven wear, cumbersome process, and reduced life of kiln doors , to achieve the effects of increased room temperature flexural strength, room temperature compressive strength, and thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

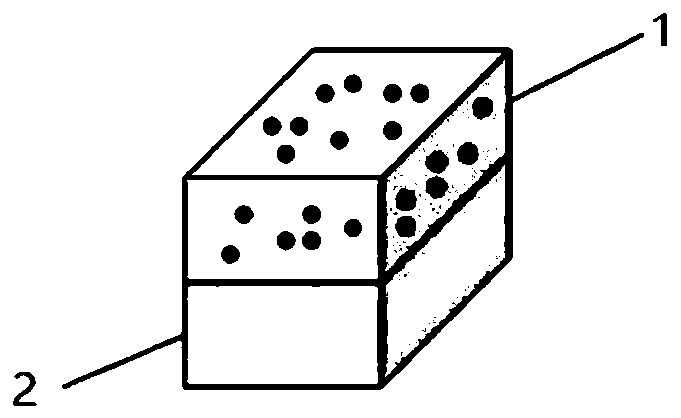

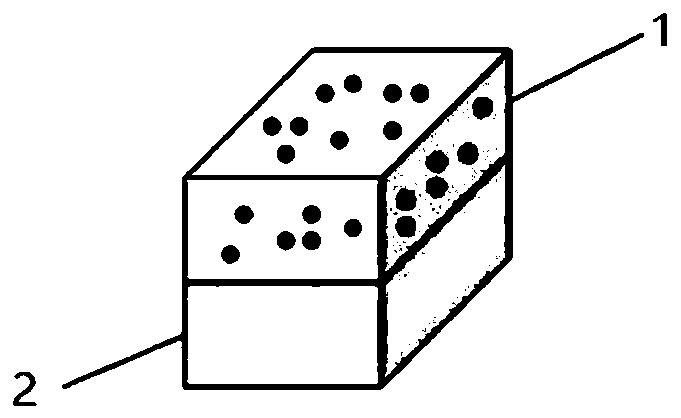

[0024] Premix 65kg of corundum aggregate, 5kg of high alumina cement, 5kg of silica fume, 5kg of alumina powder, and 20kg of bauxite fine powder in a mixer for 10 minutes to obtain premixed material 1; mix 65kg of burnt gemstone aggregate, 5kg of high alumina cement , 5kg of silica fume, 5kg of alumina powder, and 20kg of burnt gemstone fine powder were premixed in a blender for 10 minutes to obtain premixed material 2; premixed material 1 was mixed with 5 kg of water and continued to stir for 30 minutes to obtain castable 1; premixed Mix material 2 with 5kg water and continue to stir for 30 minutes to obtain castable 2; pour castable 1 to 1 / 3 of the mold volume by vibration casting, then pour castable 2 to fill the entire mold, and take off after 48 hours of curing. mold to obtain a complex-phase gradient material body; dry the complex-phase gradient material body at 100°C for 48 hours to obtain a dried complex-phase gradient material body; keep the dried complex-phase gradien...

Embodiment 2

[0027] Premix 63kg of corundum aggregate, 8kg of high alumina cement, 4kg of silica fume, 7kg of alumina powder, and 18kg of bauxite fine powder in a mixer for 10 minutes to obtain premixed material 1; mix 63kg of burnt gemstone aggregate, 8kg of high alumina cement , 4kg of silica fume, 7kg of alumina powder, and 18kg of burnt gemstone fine powder were premixed in a blender for 10 minutes to obtain premixed material 2; premixed material 1 was mixed with 5 kg of water and continued to stir for 30 minutes to obtain castable 1; premixed Mix material 2 with 5kg water and continue to stir for 30 minutes to obtain castable 2; pour castable 1 to 1 / 3 of the mold volume by vibration casting, then pour castable 2 to fill the entire mold, and take off after 48 hours of curing. mold to obtain a complex-phase gradient material body; dry the complex-phase gradient material body at 100°C for 48 hours to obtain a dried complex-phase gradient material body; keep the dried complex-phase gradien...

Embodiment 3

[0030] Premix 64kg of corundum aggregate, 7kg of high alumina cement, 4kg of silica fume, 7kg of alumina powder, and 18kg of bauxite fine powder in a mixer for 10 minutes to obtain premixed material 1; mix 64kg of burnt gemstone aggregate, 7kg of high alumina cement , 4kg of silica fume, 7kg of alumina powder, and 18kg of burnt gemstone fine powder were premixed in a blender for 10 minutes to obtain premixed material 2; premixed material 1 was mixed with 5 kg of water and continued to stir for 30 minutes to obtain castable 1; premixed Mix material 2 with 5kg water and continue to stir for 30 minutes to obtain castable 2; pour castable 1 to 1 / 3 of the mold volume by vibration casting, then pour castable 2 to fill the entire mold, and take off after 48 hours of curing. mold to obtain a complex-phase gradient material body; dry the complex-phase gradient material body at 100°C for 48 hours to obtain a dried complex-phase gradient material body; keep the dried complex-phase gradien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature flexural strength | aaaaa | aaaaa |

| Normal temperature compressive strength | aaaaa | aaaaa |

| Room temperature flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com