Anti-powder-caking dehumidifying glaze material distribution drying device and drying method and control method of anti-powder-caking dehumidifying glaze material distribution drying process

A drying device and cloth technology, applied in the field of ceramic inkjet printing, can solve the problems of affecting the decorative effect of dry-grain cloth, affecting the normal production of products, uneven distribution of dry grains, etc., so as to improve the overall decorative effect and improve the quality of glazed decoration. , The effect of improving production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

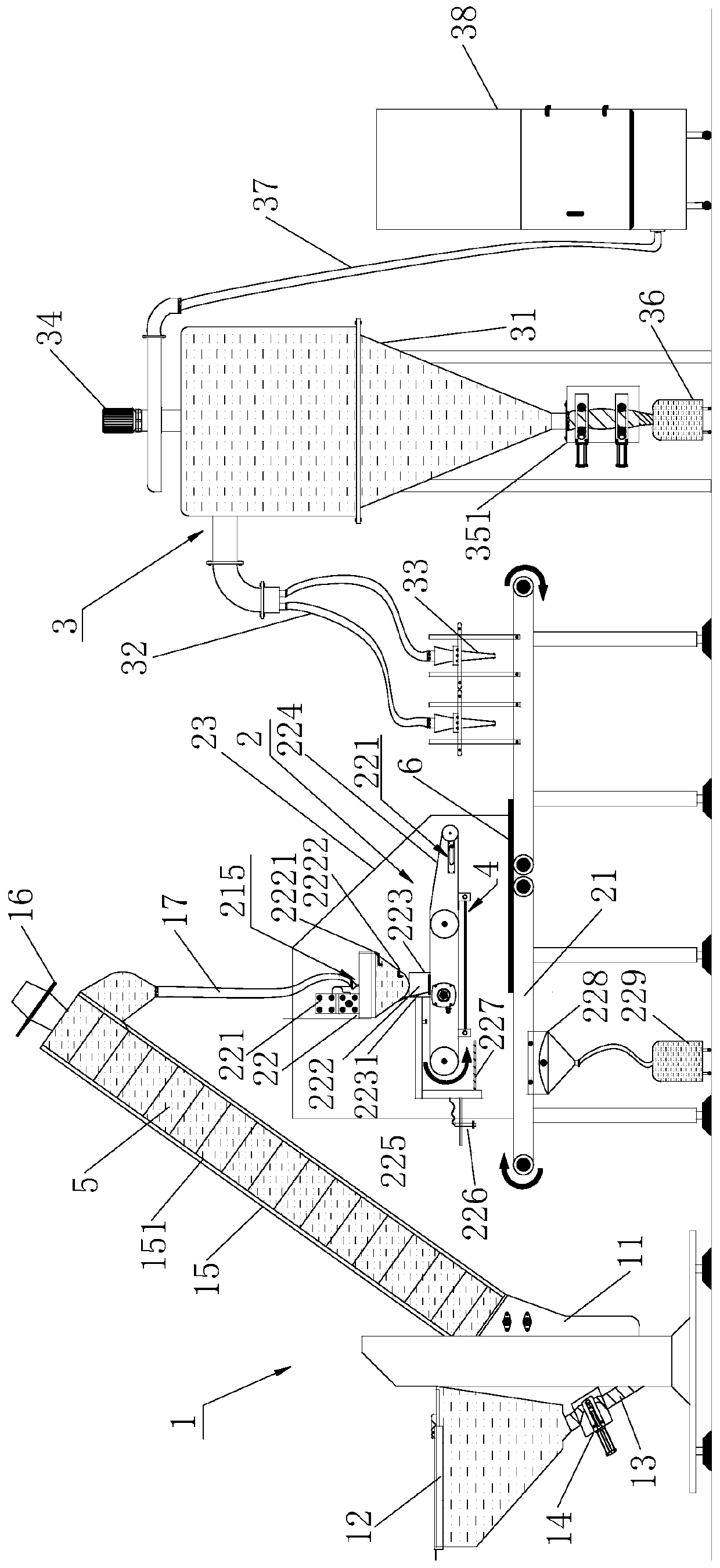

[0079] see figure 1 Shown, this anti-powder agglomeration dehumidification glaze cloth production method, it comprises the following steps:

[0080] 1) Turn on the power and start the dry grain distribution machine;

[0081] 2) According to the dry granule glaze formula, pass the dry granule through a 120-250-mesh standard screen, and control the moisture content to ≤1.5%. After mixing evenly, send it to the feed hopper of the dry granule distribution machine, and transport it to Reserve in the transitional fabric hopper;

[0082] 3) The induction electric eye in front of the cloth belt senses that the bricks are coming, and feeds back the signal to the dry grain distribution machine system. The PLC on the dry grain distribution machine issues instructions, and the cloth block will evenly distribute the above dry grain output to the cloth belt. On the cloth belt The dry granules are applied to the surface of the adobe sprayed with glue patterns through the screen, the mesh n...

Embodiment 2

[0087] The method for producing anti-powder agglomeration and dehumidification glazed cloth comprises the following steps:

[0088] 1) Turn on the power and start the dry grain distribution machine;

[0089] 2) According to the formula of glaze powder and glaze, first pass the glaze powder through a standard screen of 150-250 mesh, control the moisture content to ≤1.0%, mix it evenly, and send it to the feed hopper of the dry grain distribution machine, and transport it to Reserve in the transitional fabric hopper;

[0090] 3) The induction electric eye in front of the fabric belt senses the bricks and feeds back the signal to the dry granule distribution machine system. The PLC on the dry granule distribution machine sends out instructions, and the cloth block evenly distributes the output of the above glaze powder on the cloth belt. The glaze powder is applied to the surface of the brick adobe sprayed with glue pattern through the screen, the mesh number of the screen is 60...

Embodiment 3

[0095] The method for producing anti-powder agglomeration and dehumidification glazed cloth comprises the following steps:

[0096] 1) Turn on the power and start the dry grain distribution machine;

[0097] 2) First crush the frit according to the frit glaze formula, pass through a 80-150 mesh standard screen, control the moisture content to ≤2.0%, mix it evenly, and send it to the feed hopper of the dry grain distribution machine, and lift it through the bucket The machine is transported to the transition material hopper for standby;

[0098] 3) The induction electric eye in front of the cloth belt senses the adobe and feeds back the signal to the dry grain distributing machine system, the PLC on the dry grain distributing machine issues instructions, and the cloth blocks output the above-mentioned frit evenly on the cloth belt, and on the cloth belt The frit is distributed on the surface of the brick adobe sprayed with glue pattern through the screen, the mesh number of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com