Premix for high-yield laying hens and production method thereof

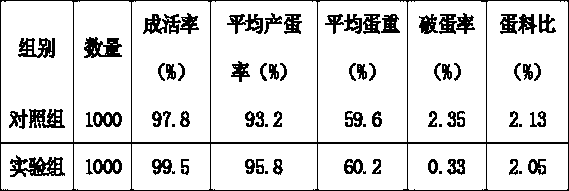

A premix, laying hen technology, applied in the direction of animal feed, animal feed, additional food elements, etc., can solve the problems of prolonging the egg production cycle, and achieve the effect of reducing the egg breaking rate, helping absorption, and prolonging the peak egg production period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A high-yielding laying hen premix: each ton of premix contains 200kg of stone powder, 220kg of calcium hydrogen phosphate, 40kg of compound trace elements, 35kg of methionine, 25kg of lysine sulfate, 60kg of table salt, 175.8kg of medical stone, rice husk Powder 150kg, Yuanming powder 30kg, choline chloride 36kg, 100-120 mesh compound Chinese herbal medicine 10kg, multivitamin 6kg, vitamin C 3kg, 25-hydroxyvitamin D3 0.2 kg, ethoxyquinoline 1kg, Pediococcus lactis 1kg, Phytase 3kg, compound enzyme for poultry 4kg.

[0023] A production method of high-yield laying hen premix, comprising the following steps:

[0024] S1, 10kg of Chinese herbal medicine mixture finely crushed to 100-120 mesh, 6kg of multivitamins, 3kg of vitamin C, 0.2kg of 25-hydroxyvitamin D3, 1kg of ethoxyquinoline, 1kg of Pediococcus lactis, 3kg of phytase, compound for poultry Enzyme 4kg, mix 5min with 50kg waist drum mixer, obtain compound;

[0025] S2, the mixture obtained from S1, stone powder 20...

Embodiment 2

[0027] A high-yielding laying hen premix: each ton of premix contains 170kg of stone powder, 180kg of calcium hydrogen phosphate, 35kg of compound trace elements, 30kg of methionine, 25kg of lysine sulfate, 60kg of table salt, 260.8kg of medical stone, rice husk 150kg powder, 30kg yuanming powder, 32kg choline chloride, 10kg compound Chinese herbal medicine of 100-120 mesh, 5kg multivitamin, 3kg vitamin C, 0.2 kg 25-hydroxyvitamin D3, 1kg ethoxyquinoline, 1kg pediococcus lactis, Phytase 3kg, compound enzyme for poultry 4kg.

[0028] A method for producing high-yield laying hen premix, comprising the following steps:

[0029] S1, finely pulverized to 100-120 mesh Chinese herbal medicine mixture 10kg, multivitamin 5kg, vitamin C 3kg, 25-hydroxyvitamin D3 0.2 kg, ethoxyquinoline 1kg, Pediococcus lactis 1kg, phytase 3kg, poultry compound Enzyme 4kg, mix 5min with 50kg waist drum mixer, obtain compound;

[0030] S2, the mixture obtained from S1, stone powder 170kg, calcium hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com