Box structure based on cold plate

A box structure and cold plate technology, which is applied in cooling/ventilation/heating transformation, casing/cabinet/drawer components, antennas, etc., can solve the limited miniaturization of the antenna structure, the difficulty of structural design and the technical requirements Improvement and other issues to achieve the effect of reducing the size and simplifying the complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

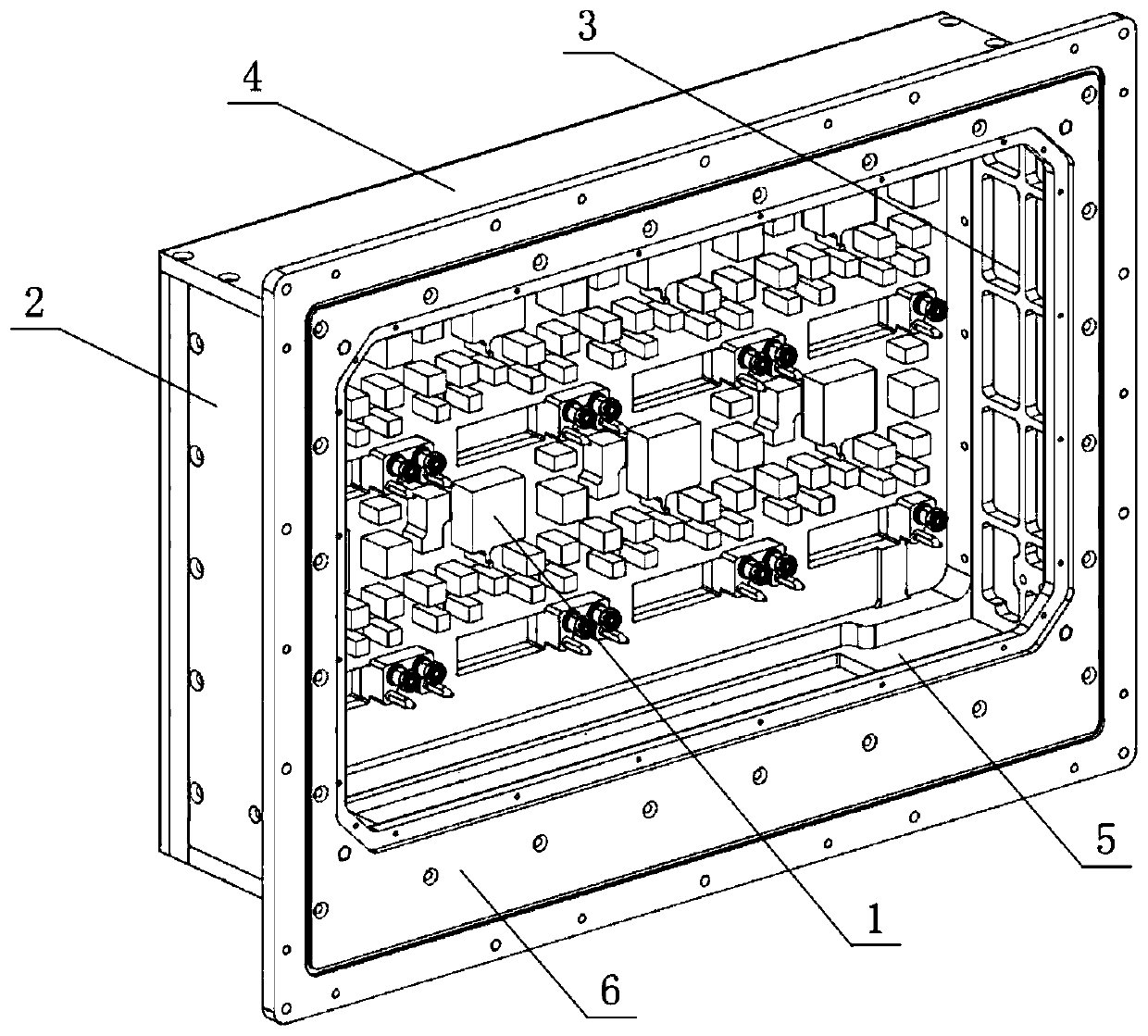

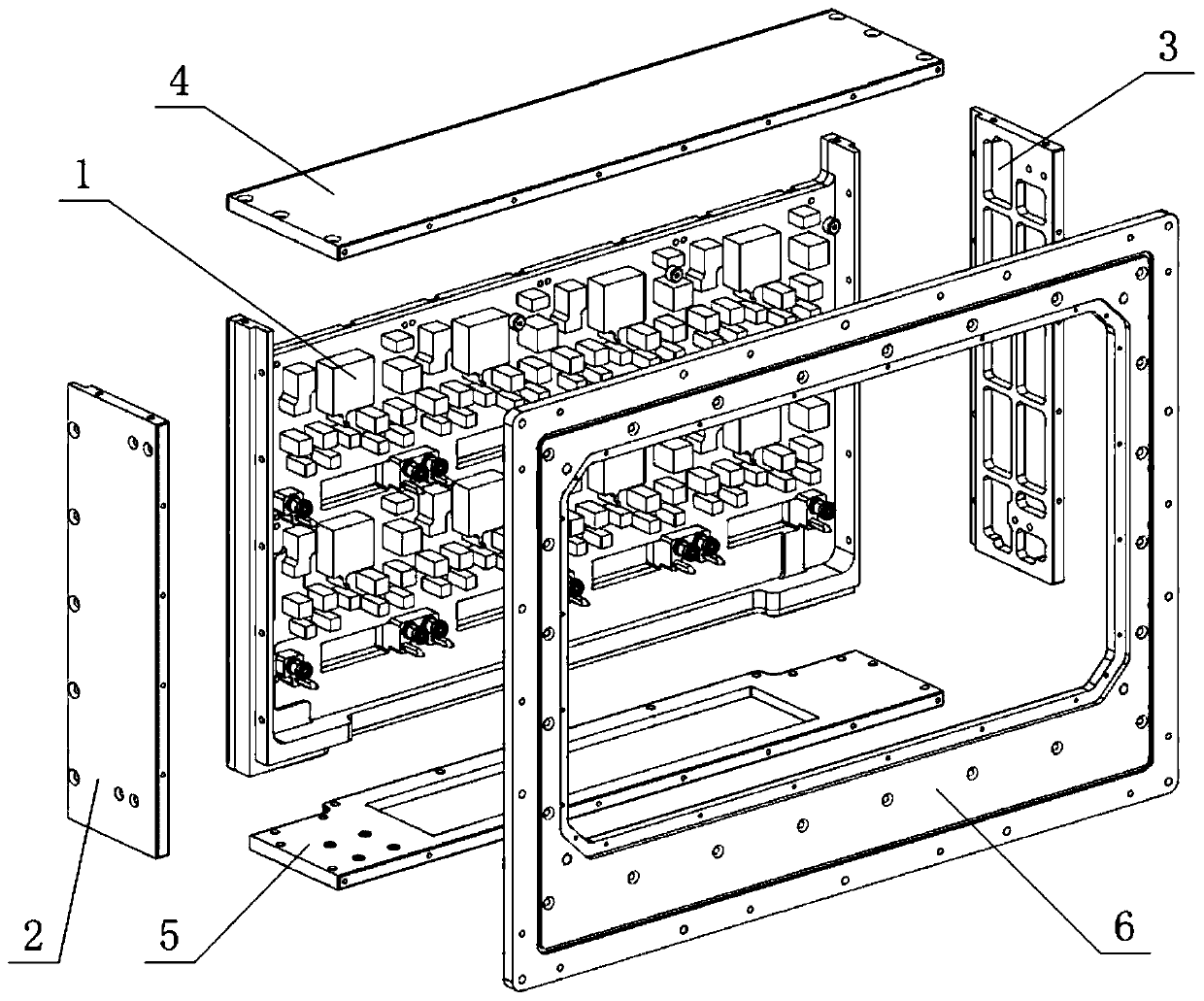

[0014] like figure 1 and figure 2 As shown, the antenna box structure is based on the cold plate 1, and the left frame 2, the right frame 3, the upper frame 4 and the lower frame 5 are respectively installed on the lapping surfaces around the cold plate 1, and the front ends of the above four frames are The surfaces are on the same plane, and are embedded in the ring-shaped platform at the back of the flange frame 6, and connected with the flange frame 6 by screws.

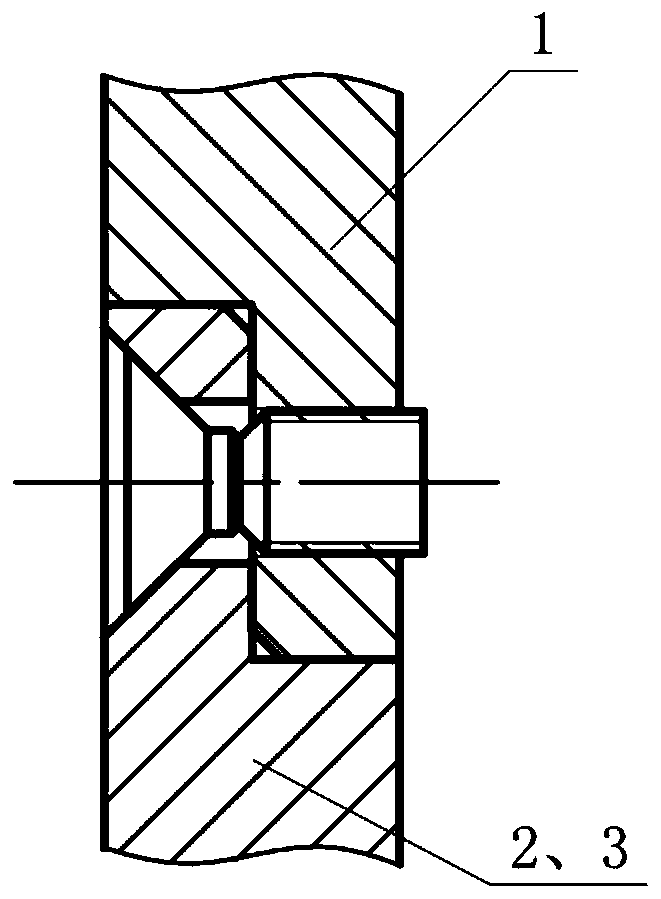

[0015] The cold plate 1 is H-shaped, and the middle area is distributed with inlet and outlet channels and cooling and heat dissipation areas to dissipate heat from the relevant heating components inside the box; the thickness of the two side areas and the bottom area of the cold plate 1 is increased compared with the middle area, and the thickness is similar to that of the middle area. The left frame 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com