Constitutive behavior construction method for multiphase metal material for high-speed deformation process

A technology of metal materials and construction methods, which is applied in the field of processing and high-speed deformation of multi-phase metal crystal materials, can solve problems such as high temperature, large strain rate, complex phase composition, etc., and achieve the effect of reducing test costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in further detail below in conjunction with accompanying drawing:

[0037] The present invention is a method for constructing the constitutive behavior of multi-phase metal materials for high-speed deformation process, which specifically includes the following steps:

[0038] Step 1), obtaining the material structure information and basic physical parameters of the target multi-phase metal material;

[0039] The material structure information includes the phase composition unit of the target multi-phase metal material, and the phase composition unit specifically refers to the phase composition of the target multi-phase metal material; the basic physical parameters include the crystal structure and correlation of each pure phase state of the target multi-phase metal material. physical parameters;

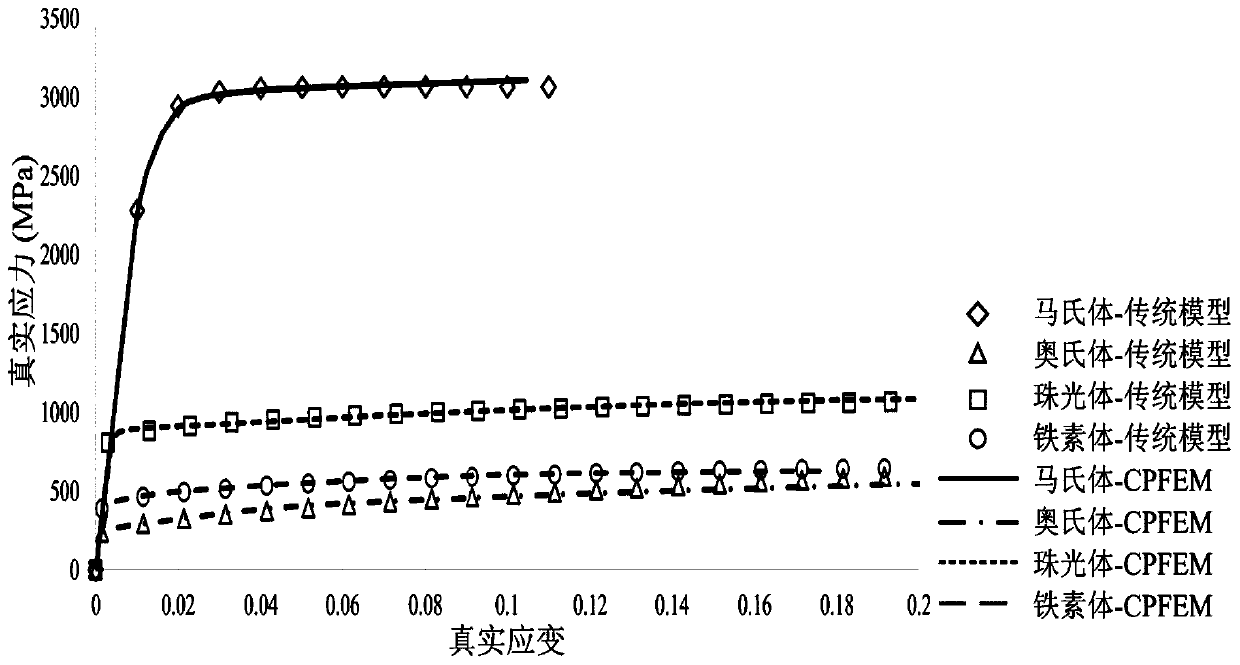

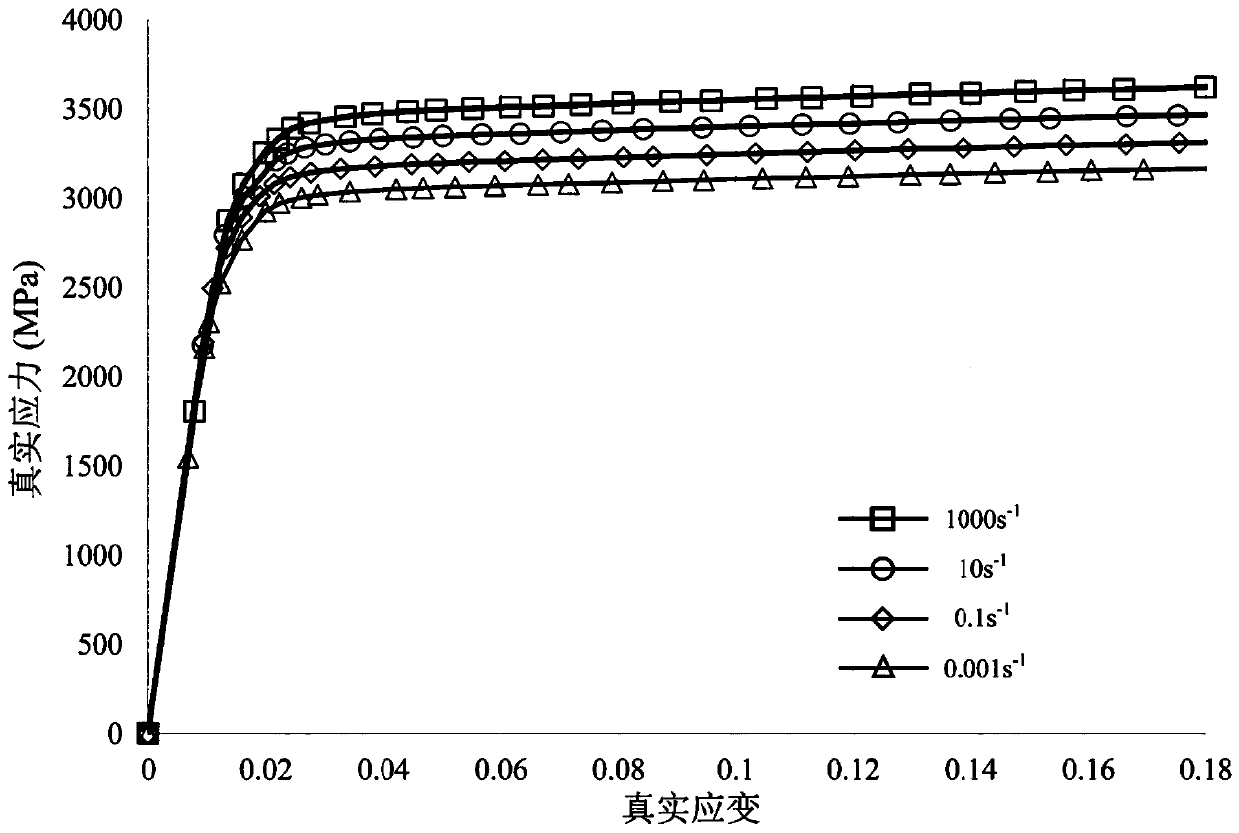

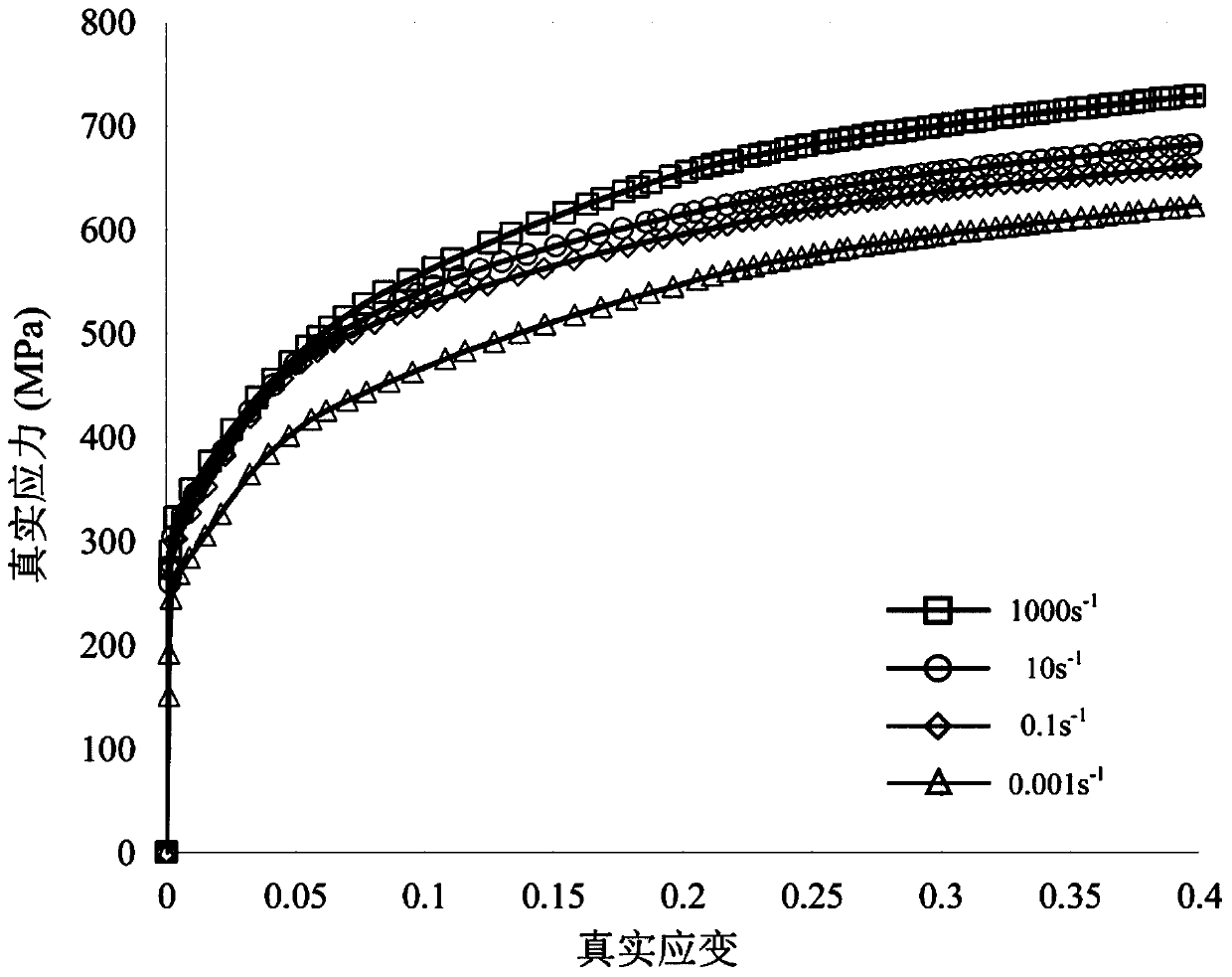

[0040] Step 2), based on the material structure information and basic physical parameters obtained in step 1), through the crystal plastici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com