A black phosphorus-tio 2 Nanotube/ti sensitive electrode hydrogen sulfide sensor

A hydrogen sulfide sensor and sensitive electrode technology, applied in nanotechnology, nanotechnology, material electrochemical variables, etc., can solve the problems of high cost, affecting application, easy poisoning of Pt, etc., achieving high anti-poisoning and anti-interference ability, good Selective, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

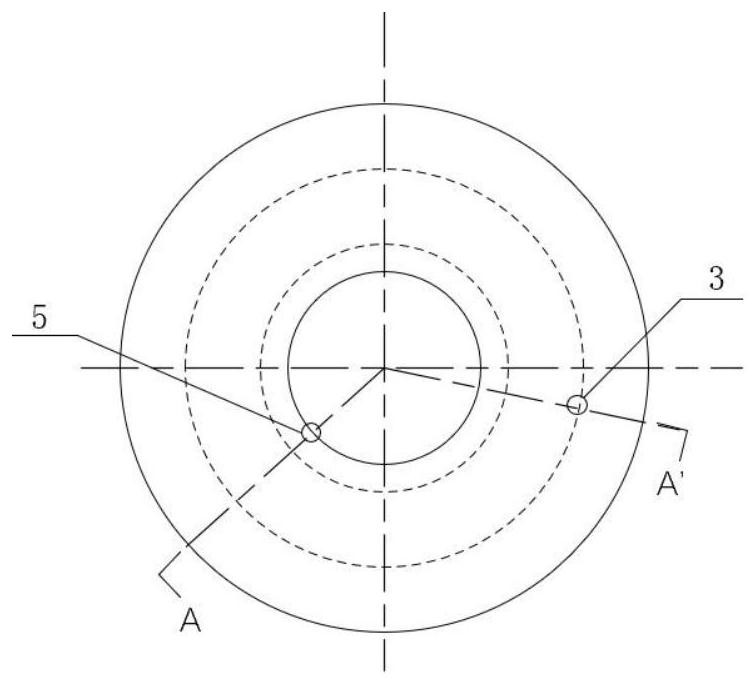

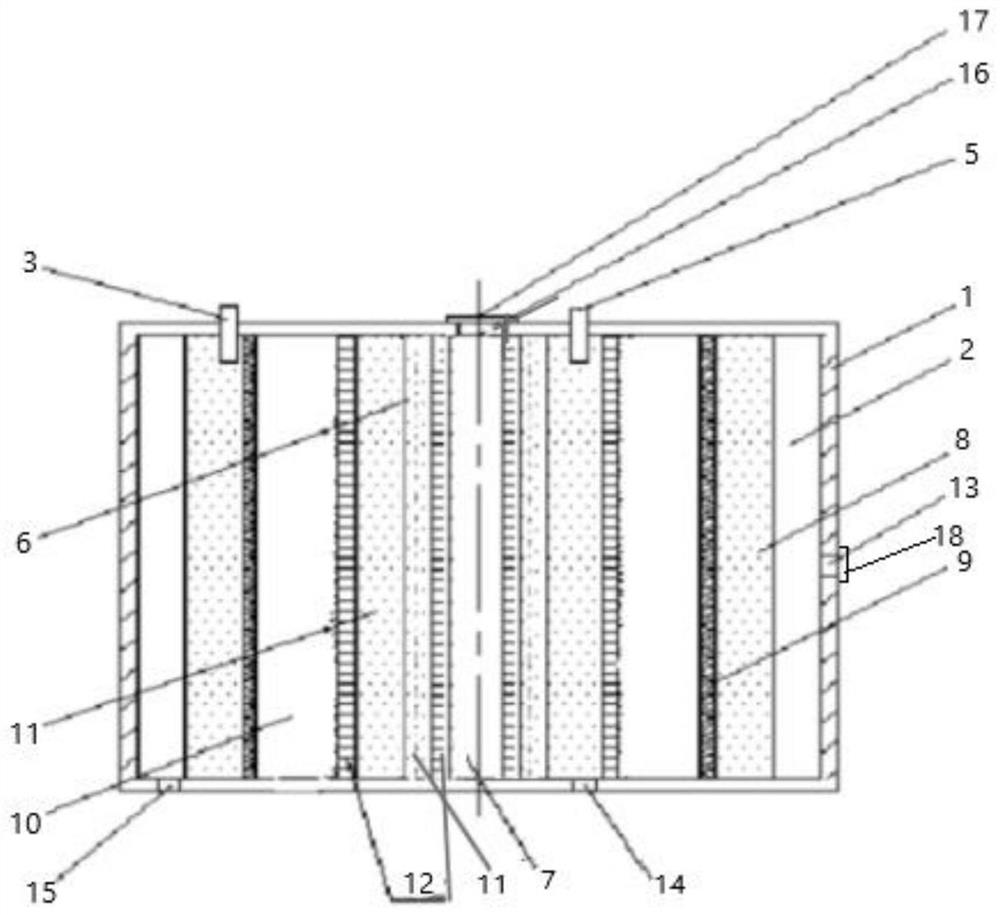

[0030] 2) TiO 2 Preparation of nanotubes / Ti: anodize the porous titanium tubes obtained through the pretreatment in step 1) in an electrolyte, the composition of the electrolyte: 0.5-1% HF, 1mol / L H 2 SO 4 The electrolysis potential is 20V, and the electrolysis time is 30-120min; after electrolysis, wash with deionized water, dry, and bake in a muffle furnace at 500°C for 3h, so that the inner and outer surfaces of the porous titanium tube generate TiO 2 nanotubes, to get TiO 2 Nanotube / Ti;

[0031] 3) Heat-treat red phosphorus at 200°C for 2 hours to remove oxides and impurities on the surface, and grind for 15 minutes after cooling;

[0032] 4) Black phosphorus-TiO 2 Preparation of Nanotube / Ti Sensitive Electrode: TiO 2 The nanotube / Ti is placed in a tube furnace, and the red phosphorus obtained in step 3) is placed on the inner and outer surfaces of the tube, at a rate of 5 cm per minute 3 Pass argon gas into the tube furnace at a high rate, raise the temperature to 6...

Embodiment 1

[0043] (1) Pretreatment of the porous titanium tube: Ultrasonic degreasing in acetone for 15 minutes, then cleaning with methanol or ethanol; then use 400g / L CrO 3 and 350g / L of H 2 SO 4 Treat for 3 minutes, ultrasonically clean with double-distilled water for 3 times, treat with 1mol / L HF for 10 minutes, ultrasonically clean with double-distilled water for 3 times, and dry.

[0044] (2)TiO 2 Preparation of nanotubes / Ti: Anodize the porous titanium tubes obtained after the pretreatment in the electrolyte, the composition of the electrolyte: 0.8% HF, 1mol / L H 2 SO 4 ; The electrolysis potential is 20V, and the electrolysis time is 80min; after the electrolysis is completed, wash with deionized water, dry, and bake in a muffle furnace at 500°C for 3h to make the inner and outer surfaces of the porous titanium tube generate TiO 2 nanotubes, to get TiO 2 Nanotube / Ti.

[0045] (3) Heat-treat red phosphorus at 200°C for 2 hours to remove oxides and impurities on the surface, a...

Embodiment 2

[0050] (1) Pretreatment of the porous titanium tube: Ultrasonic degreasing in acetone for 15 minutes, then cleaning with methanol or ethanol; then use 400g / L CrO 3 and 350g / L of H 2 SO 4 Treat for 3 minutes, ultrasonically clean with double-distilled water for 3 times, treat with 1mol / L HF for 10 minutes, ultrasonically clean with double-distilled water for 3 times, and dry.

[0051] (2)TiO 2 Preparation of nanotubes / Ti: Anodize the porous titanium tubes obtained by the pretreatment in the electrolyte, the composition of the electrolyte: 0.8% HF, 1mol / L H 2 SO 4 The electrolysis potential is 20V, and the electrolysis time is 80min; after the electrolysis is completed, wash with deionized water, dry, and roast in a muffle furnace at 500°C for 3h to make the inner and outer surfaces of the porous titanium tube generate TiO 2 nanotubes, to get TiO 2 Nanotube / Ti.

[0052] (3) Heat-treat red phosphorus at 200°C for 2 hours to remove oxides and impurities on the surface, and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com