Full-parameter probe for measuring high-subsonic three-dimensional steady-state flow field

A steady-state flow field and full-parameter technology, which is applied in the field of full-parameter probes, can solve the problems of fragile temperature sensors, insufficient flow field measurement, and low spatial resolution, so as to achieve stable temperature recovery coefficient, improve service life, and increase temperature. The effect of high recovery coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

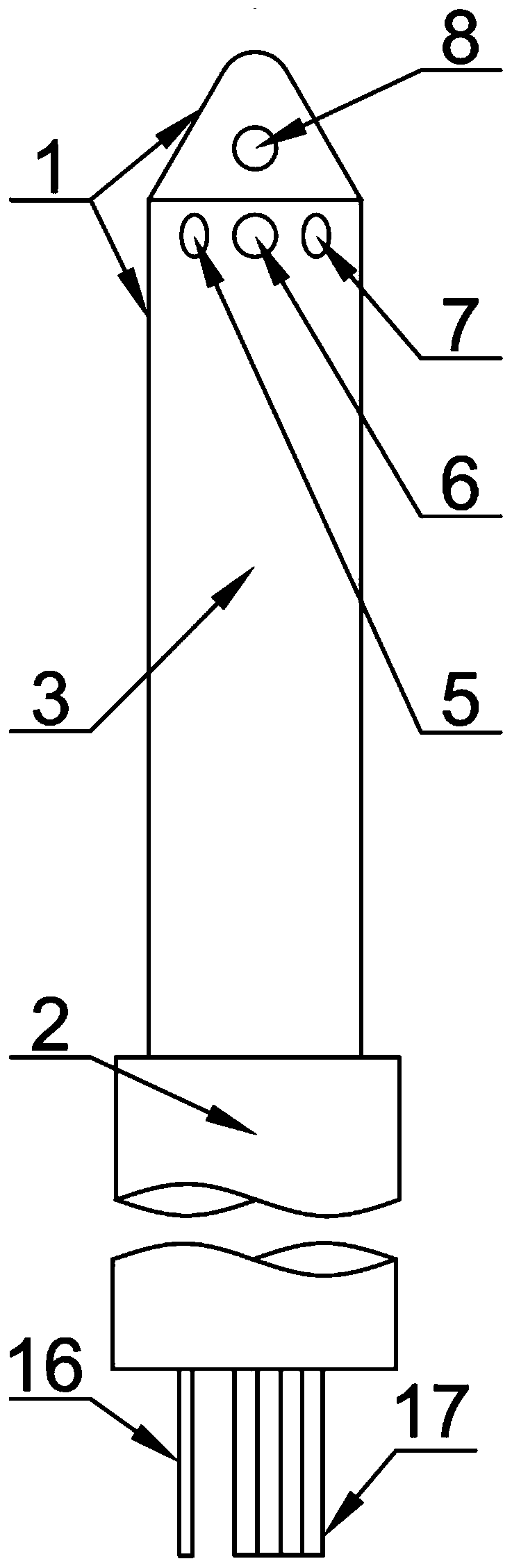

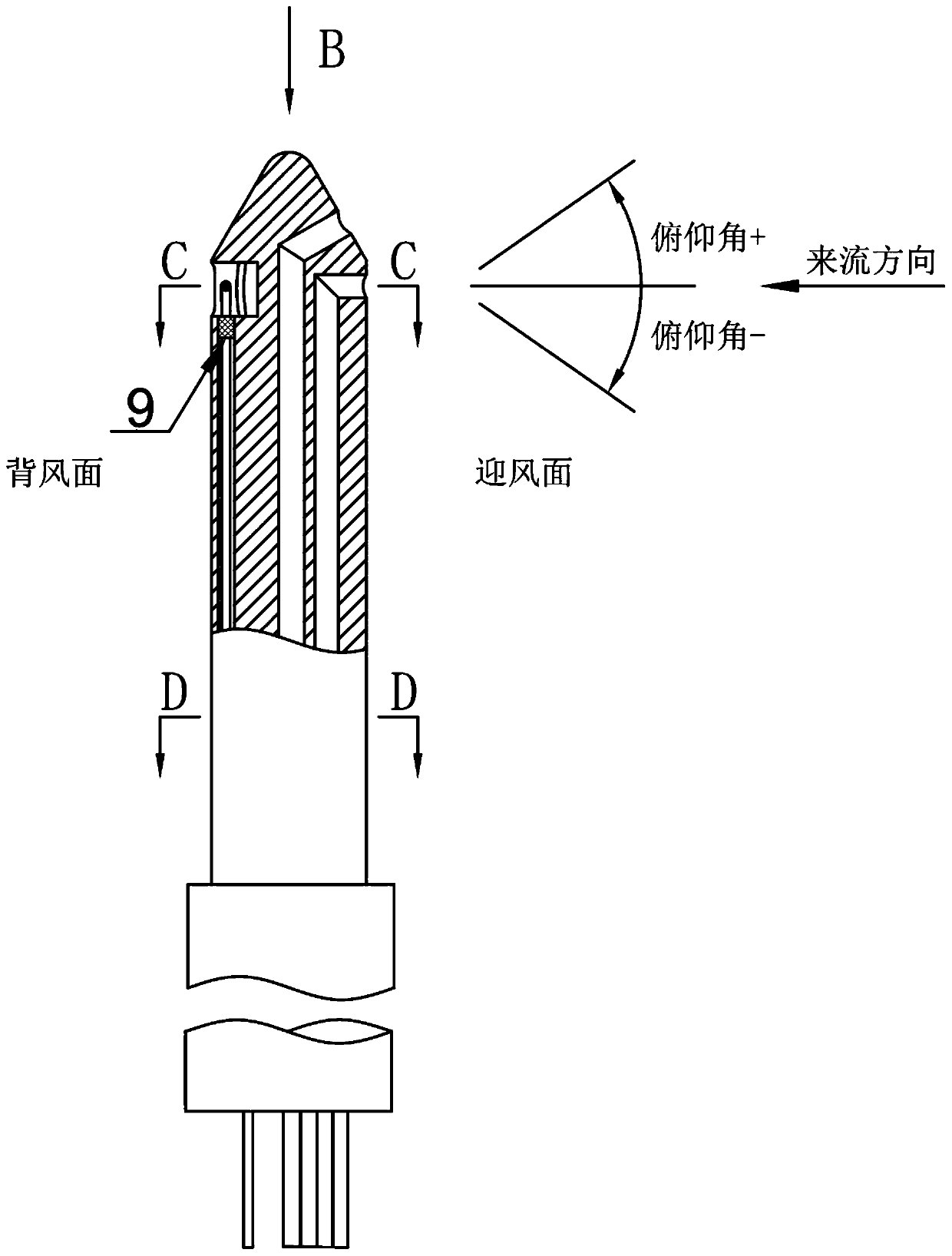

[0038] For the inlet of a high subsonic compressor, the incoming flow velocity is high and the three-dimensionality of the flow field is relatively weak, so the probe head (1) can choose a larger diameter to ensure strength and rigidity; the temperature sensor can choose a stronger armor Thermocouple; the diameter of the pressure sensing hole (5, 6, 7, 8) can be selected to be larger, and the angle between the pressure sensing left hole (5) and the pressure sensing right hole (7) can be selected to be larger, so the following can be used Described implementation mode:

[0039] Figure 1 to Figure 6 It is a structural schematic diagram of a full-parameter probe for measuring high-subsonic three-dimensional steady-state flow field of the present invention, Figure 7 It is a schematic diagram of the probe of the present invention applied to the inlet of a high subsonic compressor. The present invention consists of a probe head (1), a probe pole (2), a cylinder (3), a blunt cone...

Embodiment example 2

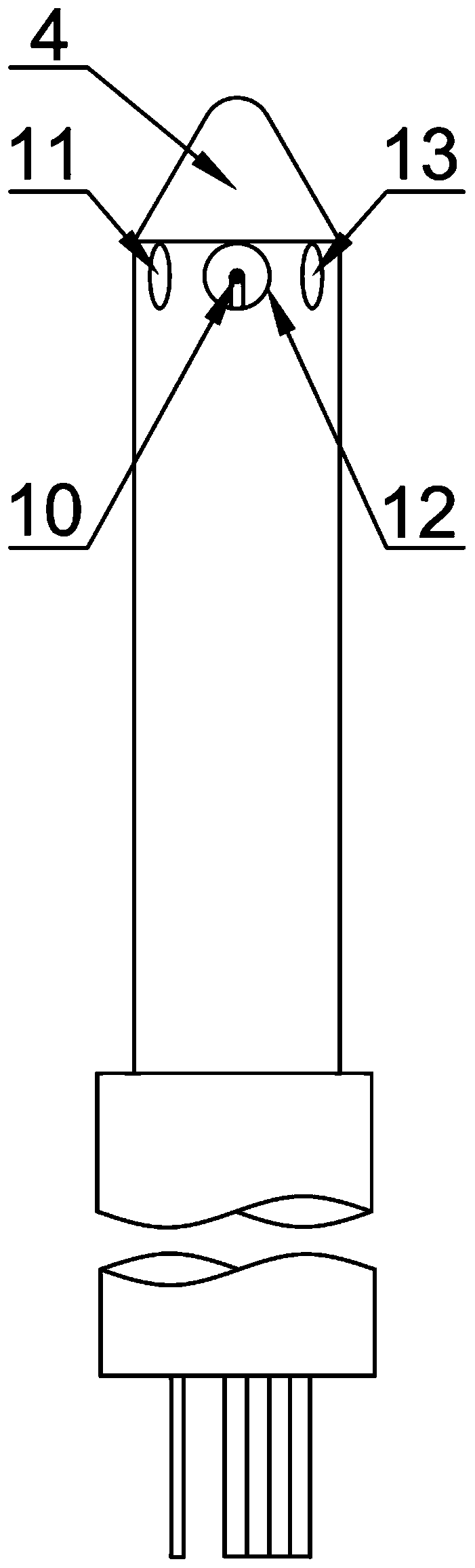

[0068] For high subsonic compressor impeller stages, the flow field velocity is relatively small, but the measurement space is narrow, and the three-dimensionality of the flow field is relatively strong, so the probe head (1) can choose a smaller diameter to ensure spatial resolution and reduce Minor disturbance of the flow field to be measured; the temperature sensor can choose a bare wire thermocouple or temperature optical fiber sensor with a high response; the diameter of the pressure sensing hole (5, 6, 7, 8) can choose a smaller diameter, and the pressure sensing hole on the left (5) A smaller angle can be selected between the pressure sensing right hole (7), so the following implementations can be adopted:

[0069] Figure 8 to Figure 13 It is a structural schematic diagram of a full-parameter probe for measuring high-subsonic three-dimensional steady-state flow field of the present invention, Figure 14 It is a schematic diagram of the probe of the present invention u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com