Heat treatment device for automobile part machining

A technology for heat treatment devices and auto parts, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problems that pit furnaces are difficult to meet processing requirements and temperature uniformity is difficult to control, and achieve small footprint, simple structure, The effect of reducing the renovation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

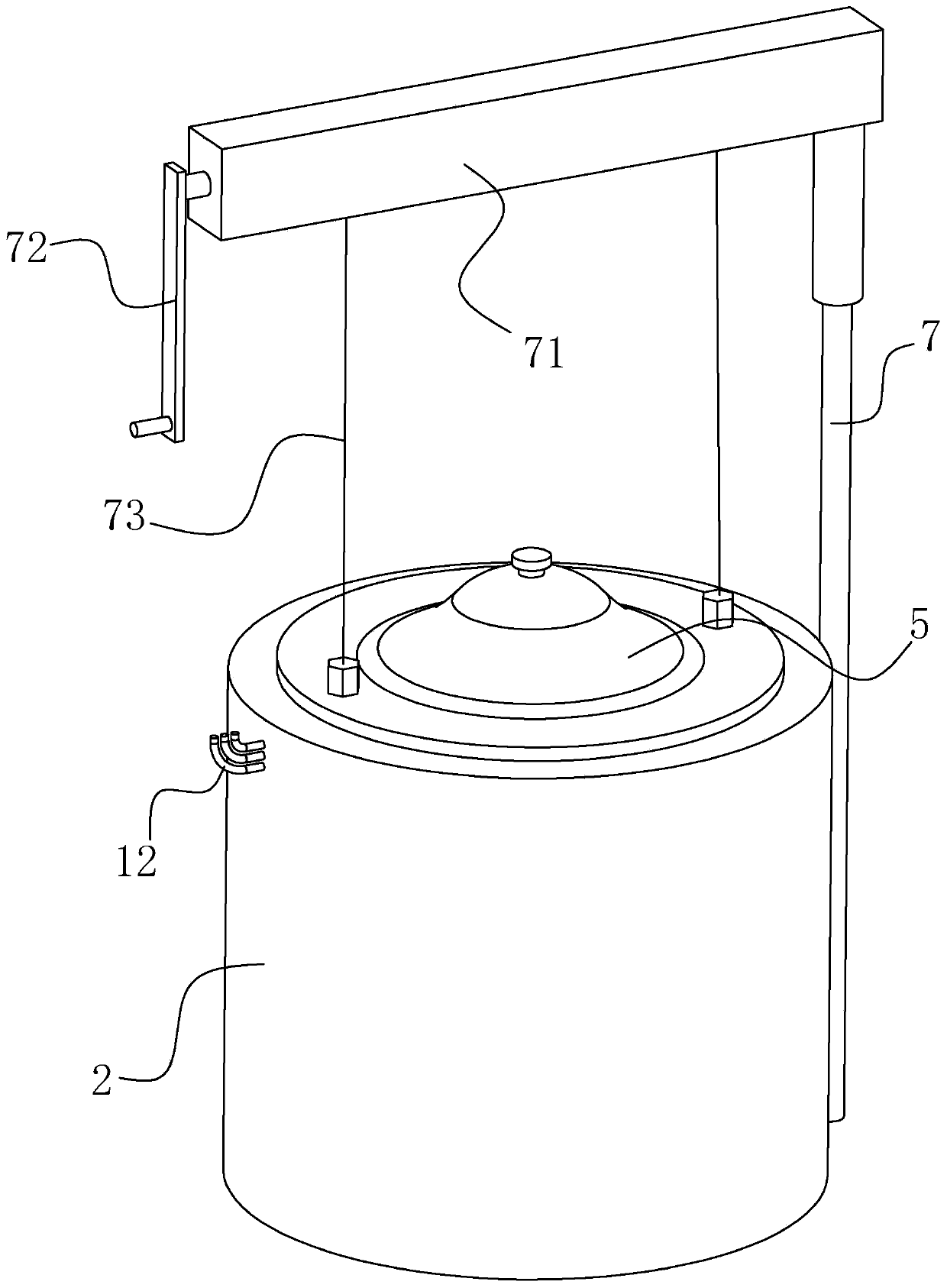

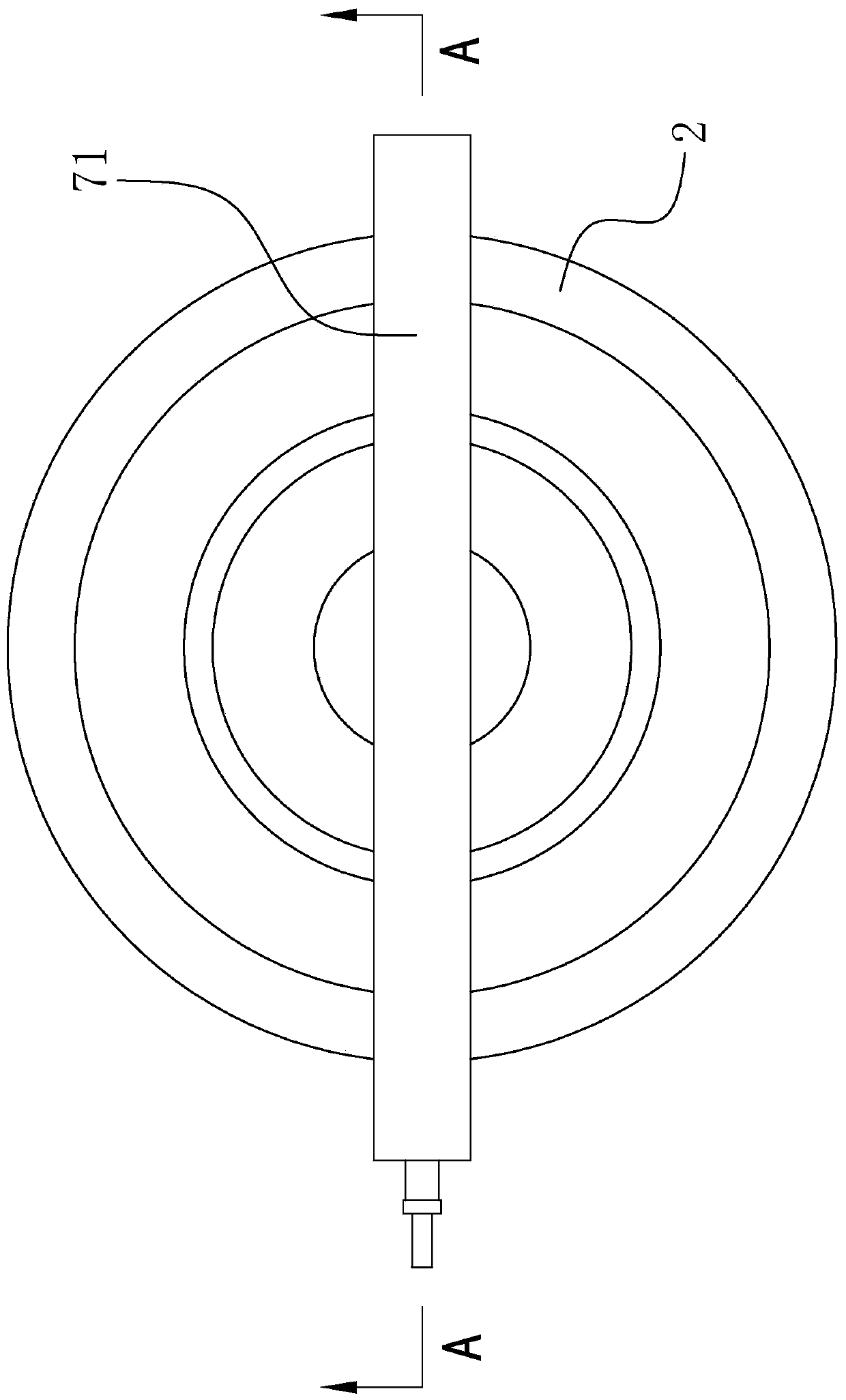

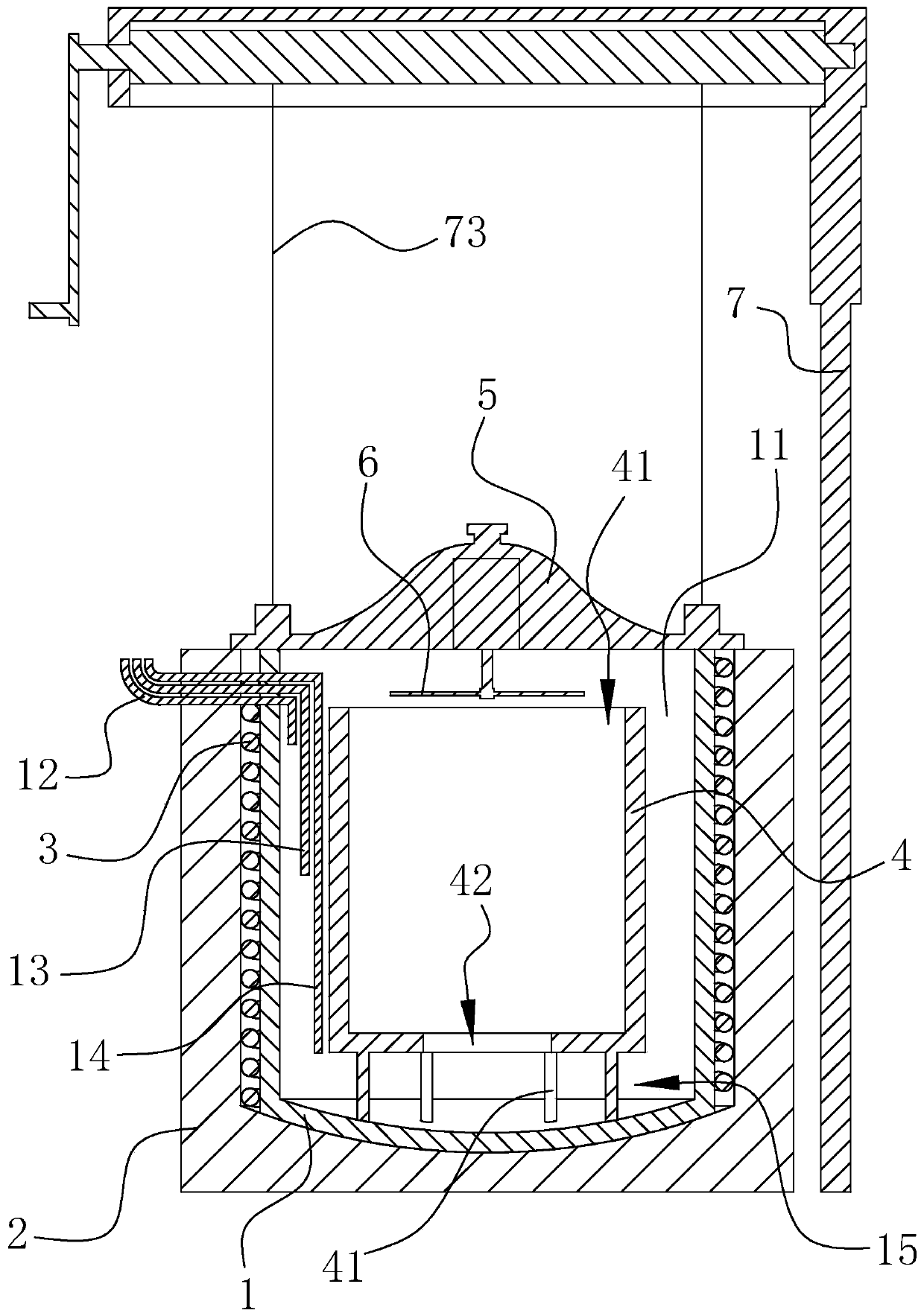

[0020] Such as Figure 1 to Figure 4 As shown, the heat treatment device for the processing of automobile parts in this embodiment includes a furnace body, a furnace cover 5 positioned at the top of the furnace body, a fan 6 arranged on the furnace cover 5 and a lifting mechanism for opening and closing the furnace cover 5, In the furnace chamber 11 of the body of heater, a diversion sleeve 4 is arranged, and the top and bottom of the diversion sleeve 4 are open, and the inner chamber of the diversion sleeve 4 is connected with the upper furnace cavity through the top opening 41, and the inner chamber of the diversion sleeve 4 The bottom opening 42 communicates with the lower furnace chamber, and there is a gap through which air can pass between the bottom surface of the diversion sleeve 4 and the bottom surface of the furnace chamber 11. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com