Water cooling type iron storage type iron runner structure

An iron ditch and iron storage technology, applied in cooling devices, discharge devices, etc., can solve problems such as inability to implement and explode, and achieve the effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be described in more detail below through specific embodiments, so as to facilitate the understanding of those skilled in the art.

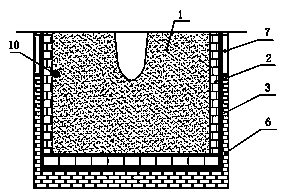

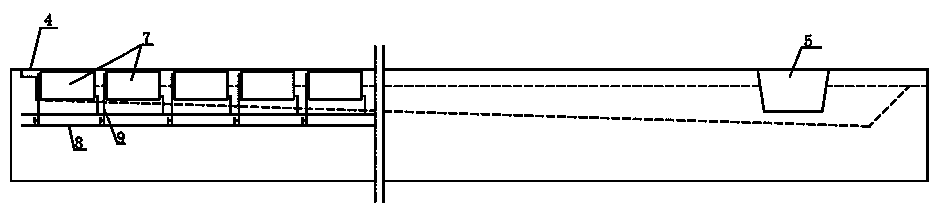

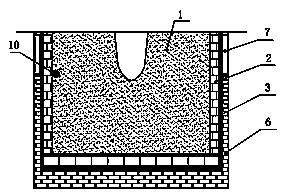

[0020] Such as figure 1 , figure 2 As shown, the water-cooled iron storage type iron gutter structure described in the present invention includes a working layer 1 that is in direct contact with the high-temperature mixed solution, and a permanent layer 2 and a steel shell 3 that are coated outside the working layer 1; in order to achieve a good Heat conduction effect, the present invention uses carbon composite bricks (heat conduction at room temperature ≥ 13 W / m·K, compressive strength ≥ 45MPa) to build the permanent layer; the steel shell between the iron tap hole 4 and the skimmer 5 A water cooling device is installed on the outer wall. In order to achieve a good cooling effect, a water cooling device can be installed outside the steel shell between the taphole 4 and the skimmer 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com