Urethral drug delivery device for urinary surgery

A technology for urology and drug delivery device is applied in the field of urethral drug delivery device for urology surgery, which can solve the problems of inability to automatically pressurize and spray liquid medicine, inconvenient for hand-held operation, inconvenient for cleaning and disinfection, etc., and achieves convenient cleaning and disinfection, Hand-held and easy-to-operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

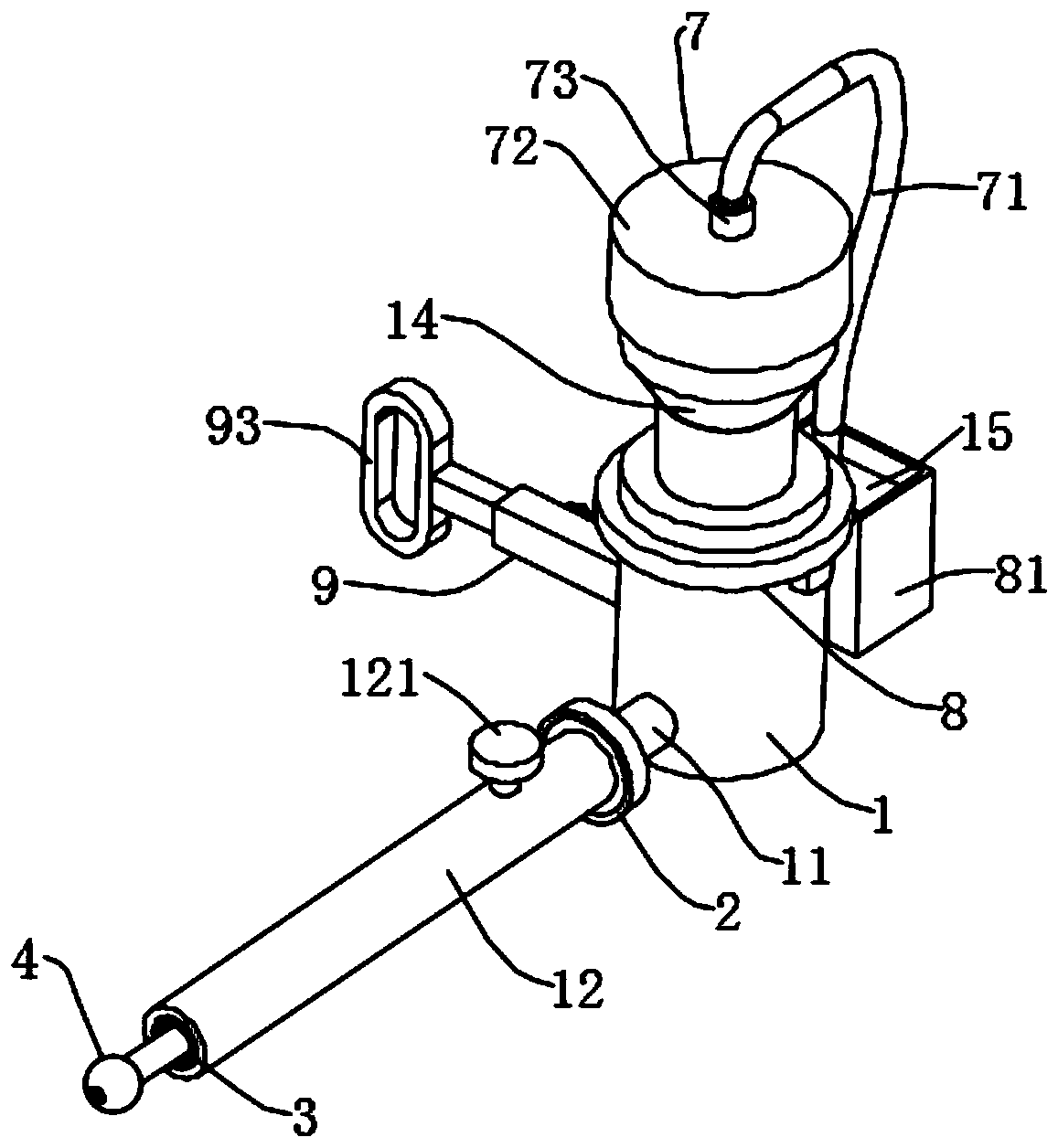

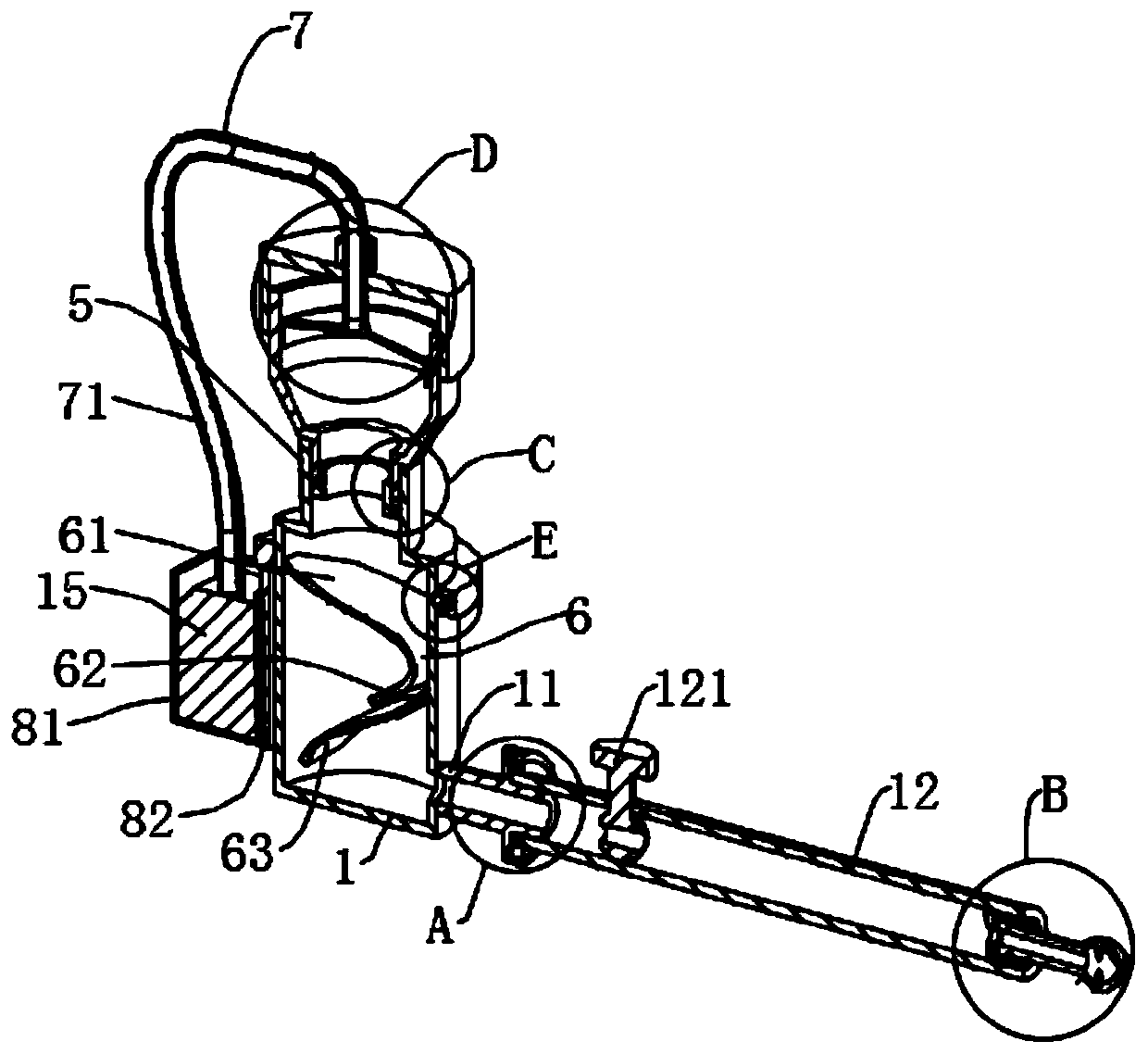

[0056] refer to figure 1 and figure 2 , a urethral applicator for urology, mainly including the following parts:

[0057] Mixing cartridge 1, the mixing cartridge 1 is used to place medicinal liquid;

[0058] communicate with the first pipeline 11 fixed on the mixing cartridge 1;

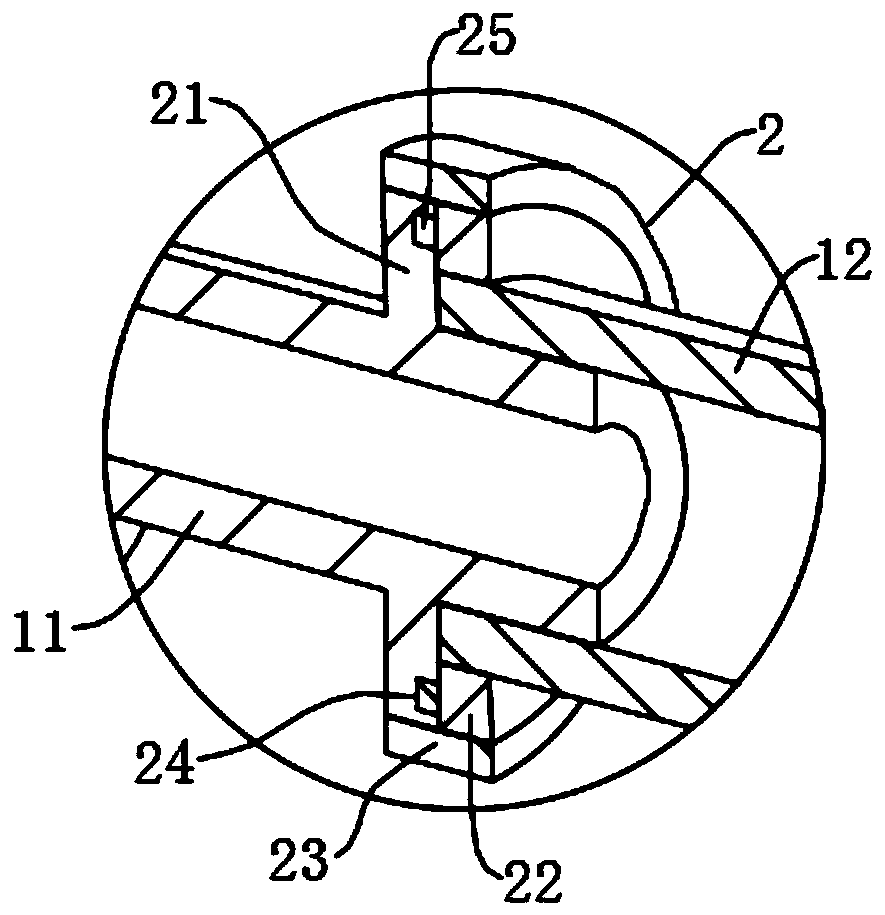

[0059] The second pipeline 12 communicated with the first pipeline 11 and fixed through the first connection assembly 2;

[0060] a valve 121 installed on the second pipeline 12;

[0061] communicate with the drug delivery tube 13 fixed at the end of the second pipeline 12 through the second connection assembly 3;

[0062] The drug delivery assembly 4 arranged at the end of the drug delivery tube 13;

[0063] Disassemble the drug hopper 14 connected to the top of the mixing cartridge 1 through the third connection assembly 5;

[0064] The anti-foaming component 6 arranged in the mixing cartridge 1;

[0065] Micro air pump 15 for pressurization;

[0066] It is used to deliver the air pressur...

Embodiment 2

[0083] The difference from Example 1 is that the inner wall of the mixing cartridge 1 is also coated with an antifouling coating. Since the mixing cartridge 1 is used to store the medicinal solution, the medicinal solution is likely to remain in the mixing cartridge 1. It is convenient to clean the surface of the mixing cartridge 1, so a layer of antifouling coating is sprayed on the inner wall of the mixing cartridge 1, wherein the antifouling coating is prepared by the following method:

[0084] Take the following raw materials of each component by weight for later use: 50 parts of polytetrafluoroethylene, 50 parts of polypropylene, 40 parts of polyethylene, 30 parts of polycarbonate, 10 parts of polymethacrylate, 30 parts of dimethyl adipate , 20 parts of pentaerythritol, 20 parts of alkanolamide, 30 parts of diphenyl ethyl ketone, 10 parts of hydroxyethylated fatty amine, 10 parts of ethyl acetate;

[0085] S1. Prepare antifouling coating pre-preparation solution; mix and ...

Embodiment 3

[0090] The difference from Example 2 is the preparation of the antifouling coating on the inner wall of the mixing cartridge 1, wherein the antifouling coating is prepared by the following method:

[0091] Take the following components by weight for subsequent use: 55 parts of polytetrafluoroethylene, 55 parts of polypropylene, 45 parts of polyethylene, 35 parts of polycarbonate, 18 parts of polymethacrylate, 30 parts of dimethyl adipate , 20 parts of pentaerythritol, 20 parts of alkanolamide, 30 parts of diphenyl ethyl ketone, 10 parts of hydroxyethylated fatty amine, 10 parts of ethyl acetate;

[0092] S1. Prepare antifouling coating pre-preparation solution; mix and stir polytetrafluoroethylene, polypropylene, polyethylene, polycarbonate, and polymethacrylate evenly, then add it to the reaction kettle and heat it to 235°C, then keep it warm for 20min ;

[0093] S2. Preparation of antifouling coating solution: After cooling the antifouling coating pre-preparation solution o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com