Heat dissipation type magnesium alloy die-casting box

A magnesium alloy and heat-dissipating technology, applied in the field of heat-dissipating magnesium alloy die-casting boxes, can solve the problems of increased cost, burden, fan damage, etc., and achieves the effects of fast heat dissipation, wide heat dissipation space, and reduced loss and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

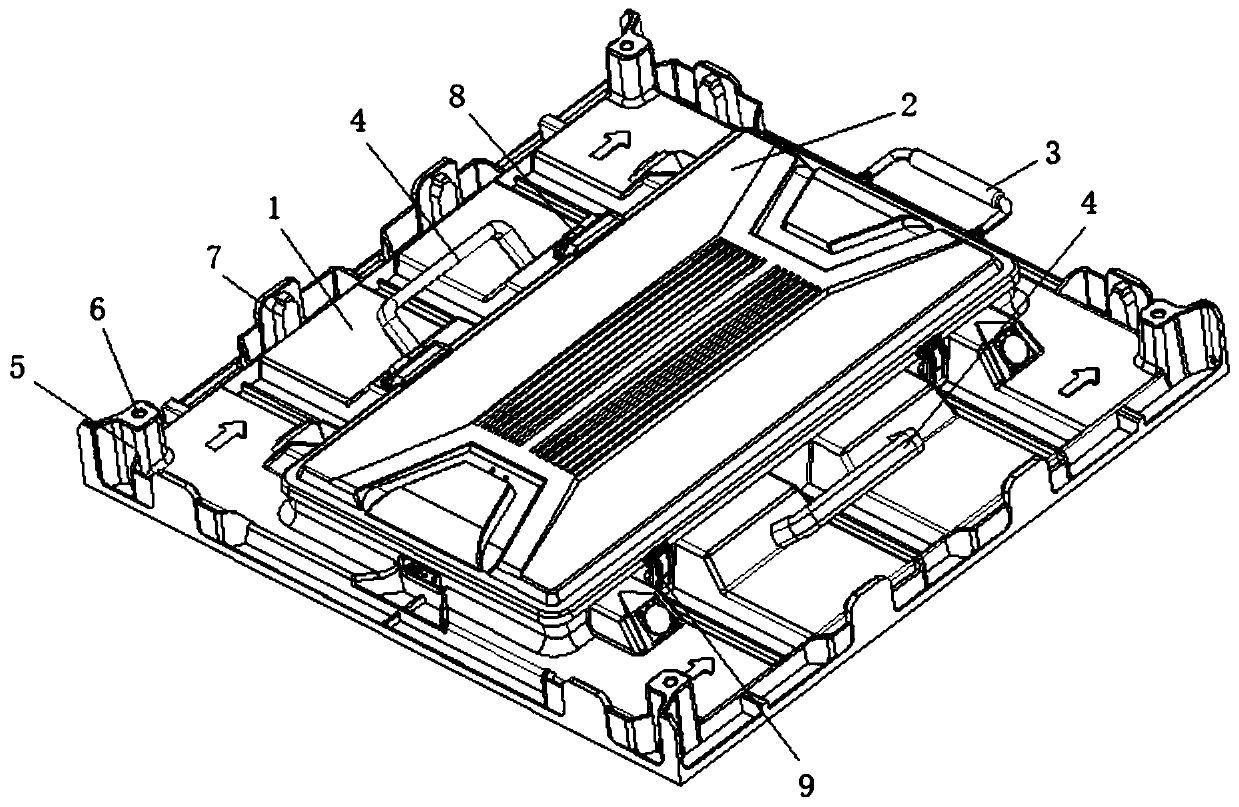

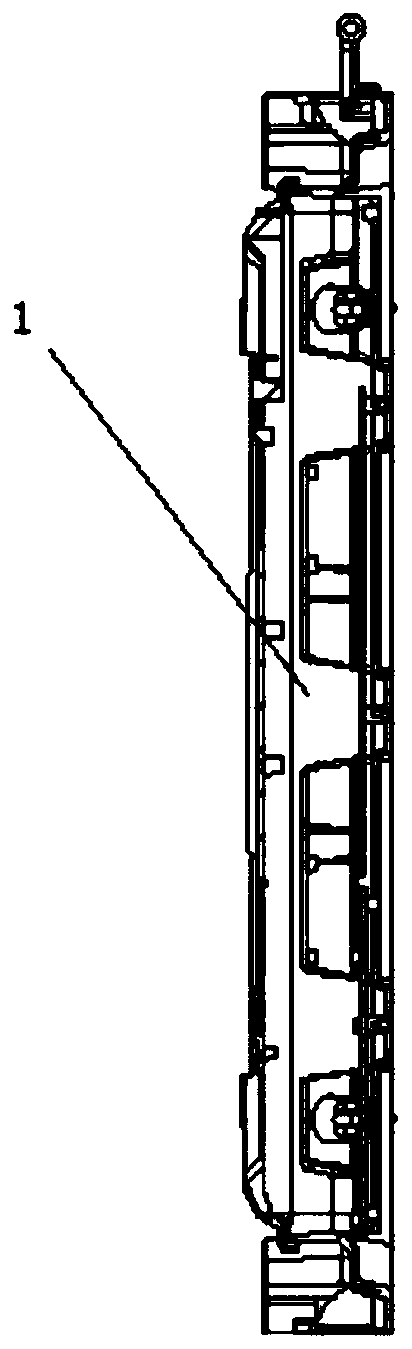

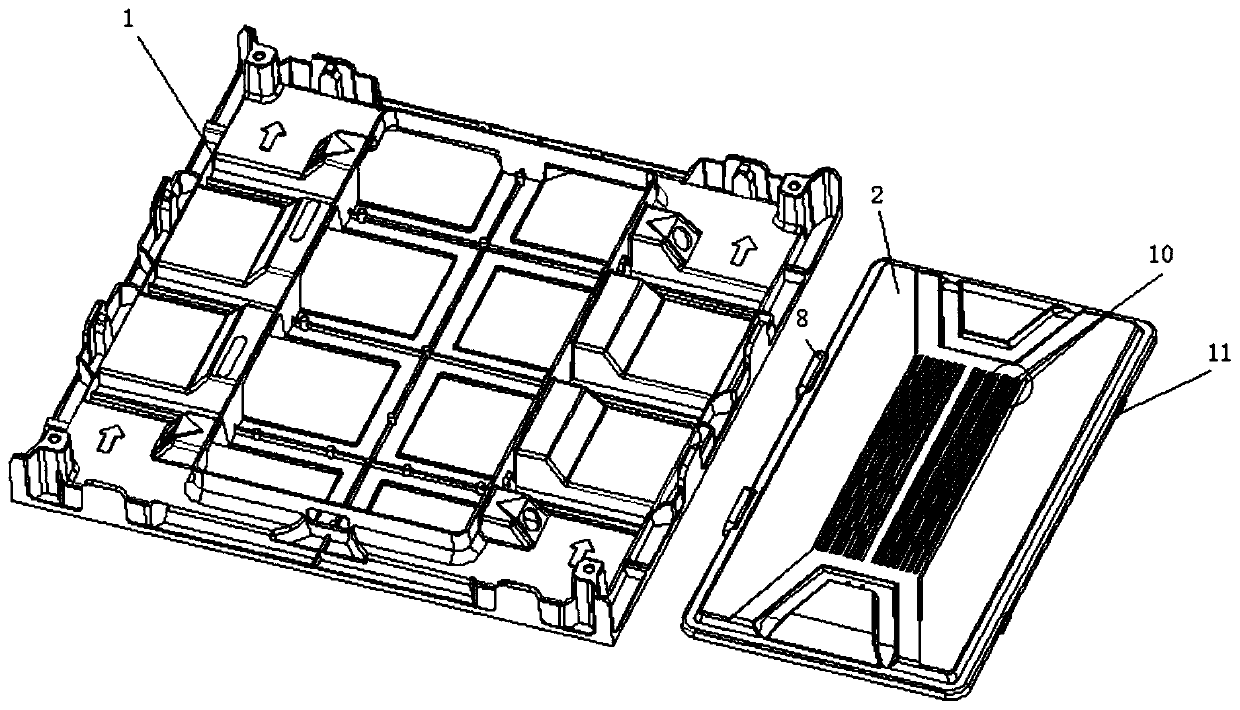

[0024] see Figure 1-6 , according to an embodiment of the present invention, a heat-dissipating magnesium alloy die-casting box includes a die-casting box body 1 and a heat-dissipating door panel 2. Positioning columns 5 are provided at the four corners of the top of the die-casting box body 1, and the center of the positioning column 5 is provided with Positioning holes 6, the four sides of the die-casting box body 1 are provided with several fast lock plates 7 at intervals, the heat dissipation door panel 2 is a rectangular structure as a whole, and the middle part of the top surface of the heat dissipation door panel 2 is provided with several strip-shaped heat dissipation grooves at intervals 10. Two hinges 8 are arranged at intervals on one side of the heat dissipation door panel 2, and two lock pieces 11 are arranged at intervals on the other side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com