Magnesium alloy die-casting box with high heat dissipation efficiency

A technology of heat dissipation efficiency and magnesium alloy, applied in metal casing, cooling/ventilation/heating transformation, chassis/cabinet/drawer parts and other directions, can solve the problems of fan damage and increase cost, achieve fast heat dissipation, reduce Fan loss and cost, the effect of wide cooling space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

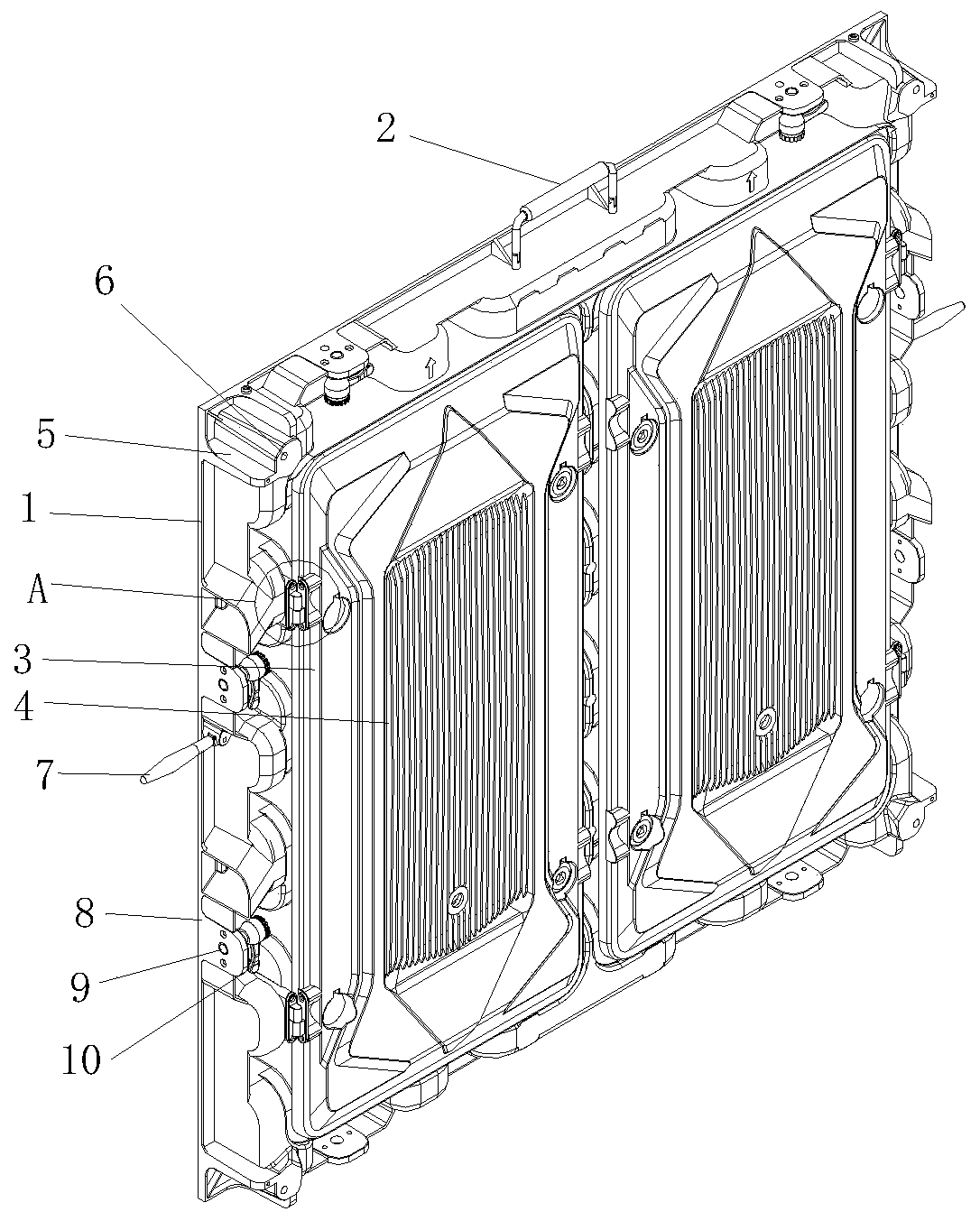

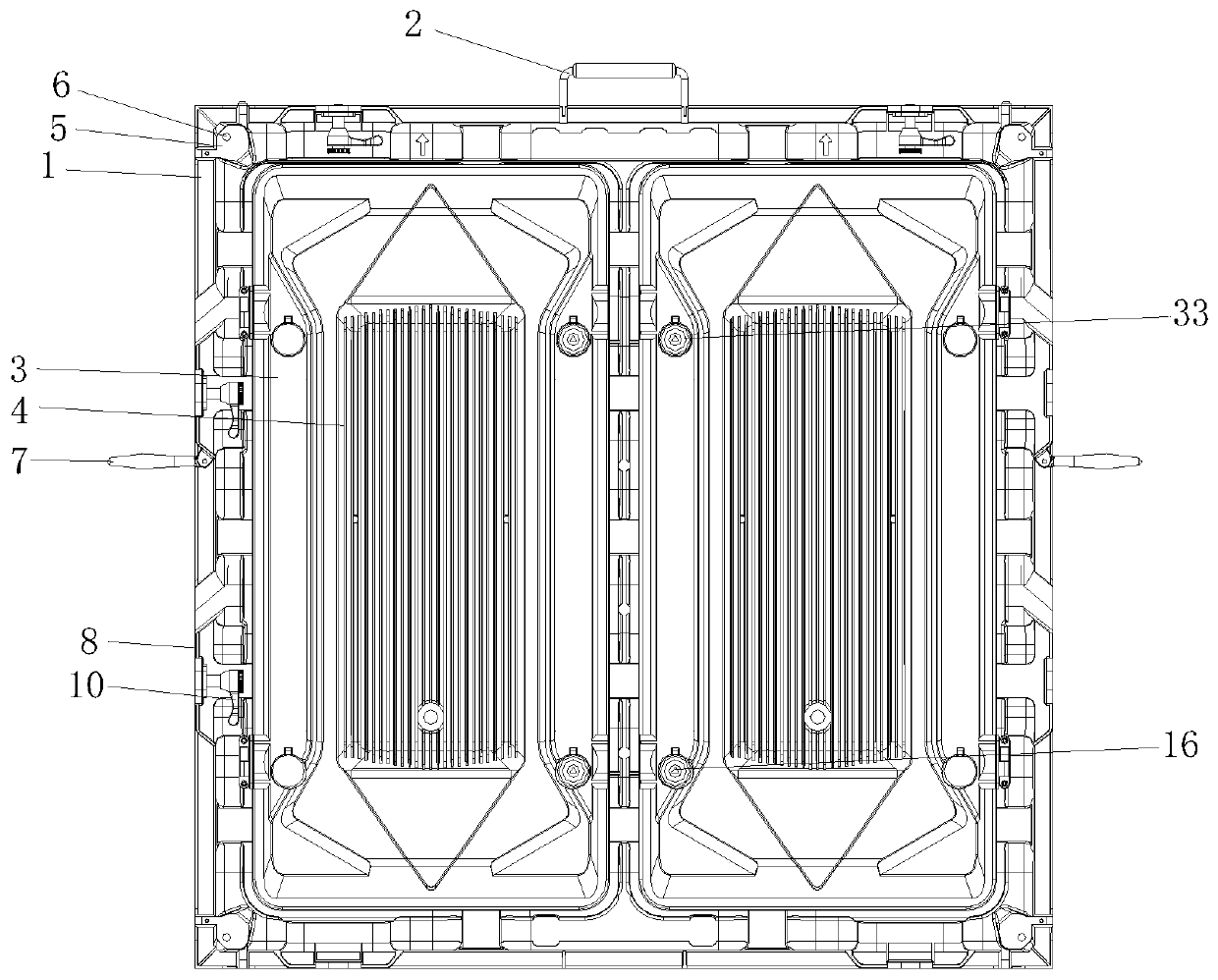

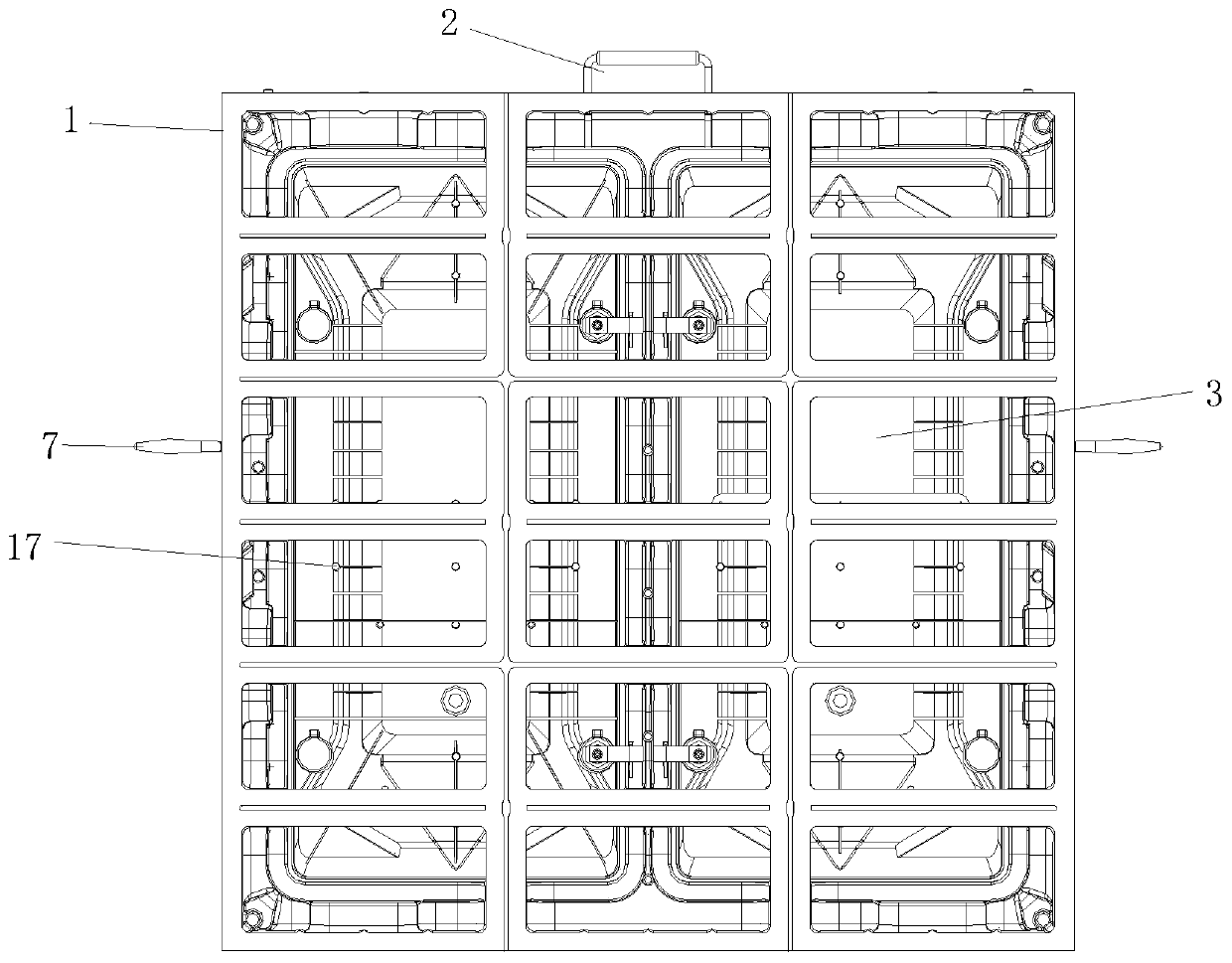

[0028] see Figure 1-12 , a magnesium alloy die-casting box with high heat dissipation efficiency according to an embodiment of the present invention, comprising a die-casting box body 1 and a heat dissipation structure 3, the die-casting box body 1 is provided with a partition protrusion 13, and both sides of the partition protrusion 13 are provided There are heat dissipation structures 3, each heat dissipation structure 3 includes a third protrusion 36, and the outside of the third protrusion 36 is provided with a plurality of outwardly protruding heat dissipation strips 4, and the heat dissipation structure 3 and the heat dissipation strips 4 are integrated structure, the inside of each heat dissipation structure 3 is provided with a plurality of second protrusions 31, and one side of each second protrusion 31 is provided with a plurality of connecting bars ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com