Axial flux outer rotor hub motor

An axial magnetic flux, in-wheel motor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit, electric components, etc., can solve the problems of blocking the heat dissipation of the stator iron core winding, the weight of the oil cooling device and the dynamic sealing problem. Achieve the effect of increasing heat dissipation, good heat dissipation and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

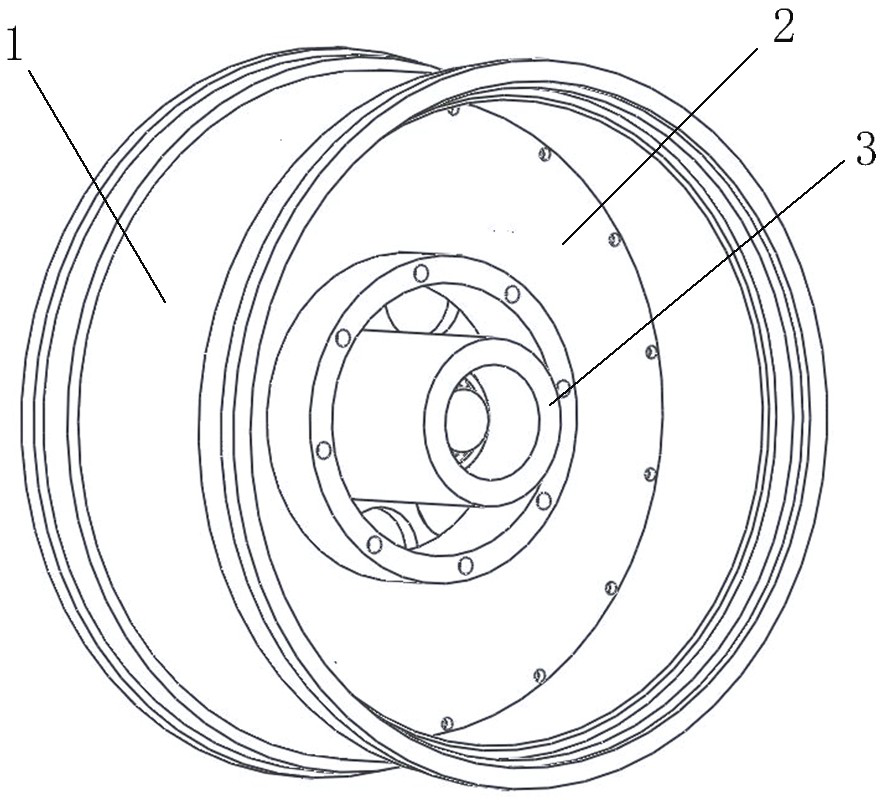

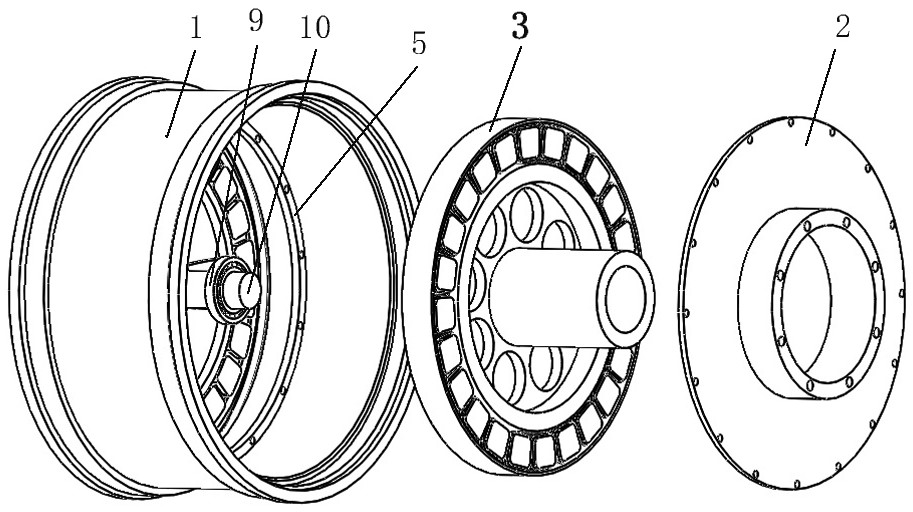

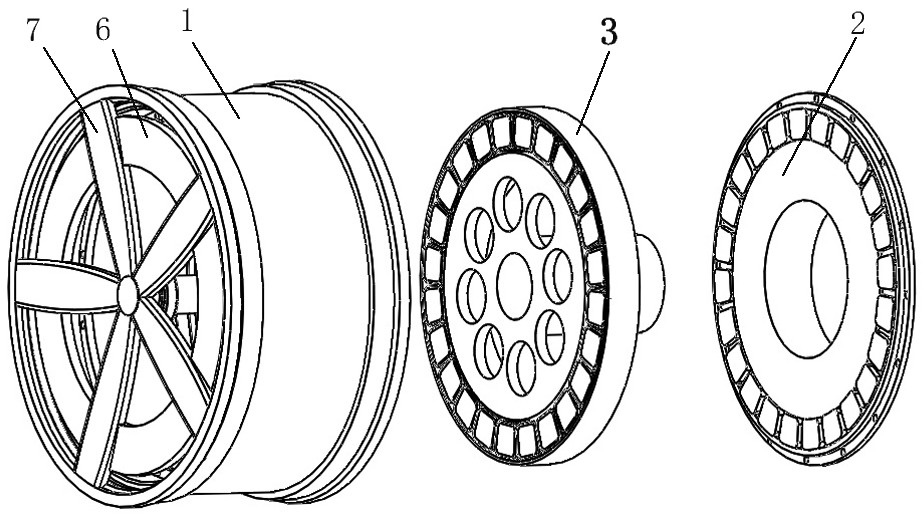

[0028] see attached Figure 1-6 It is an embodiment of the present invention, which discloses an axial magnetic flux outer rotor hub motor, including an outer rotor hub 1, the outer rotor hub 1 is provided with a rotor disk 6 at one end and a rotating shaft 10 in the center. A plurality of permanent magnets 11 are evenly arranged on the surface of the rotor disk 6 along the circumferential direction, and the plurality of permanent magnets 11 on the rotor disk 6 form a first permanent magnet group.

[0029] The outer rotor hub 1 is also fixedly provided with a hub brake pad connecting plate 2. The surface of the hub brake pad connecting plate 2 is provided with a plurality of permanent magnets 11 evenly distributed along the circumferential direction. The magnets 11 constitute a second permanent magnet group.

[0030] An inner stator assembly 3 is arranged between the rotor disk 6 and the hub brake pad connecting plate 2 , and the inner stator assembly 3 includes a stator disk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com