A kind of catalytic slurry, membrane electrode and its preparation method and application

A membrane electrode and catalytic slurry technology, used in battery electrodes, circuits, fuel cells, etc., can solve the problems of no reduction in current density and durability, swelling and deformation of proton exchange membranes, and low performance of membrane electrodes, etc. The effect of reducing activation polarization and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

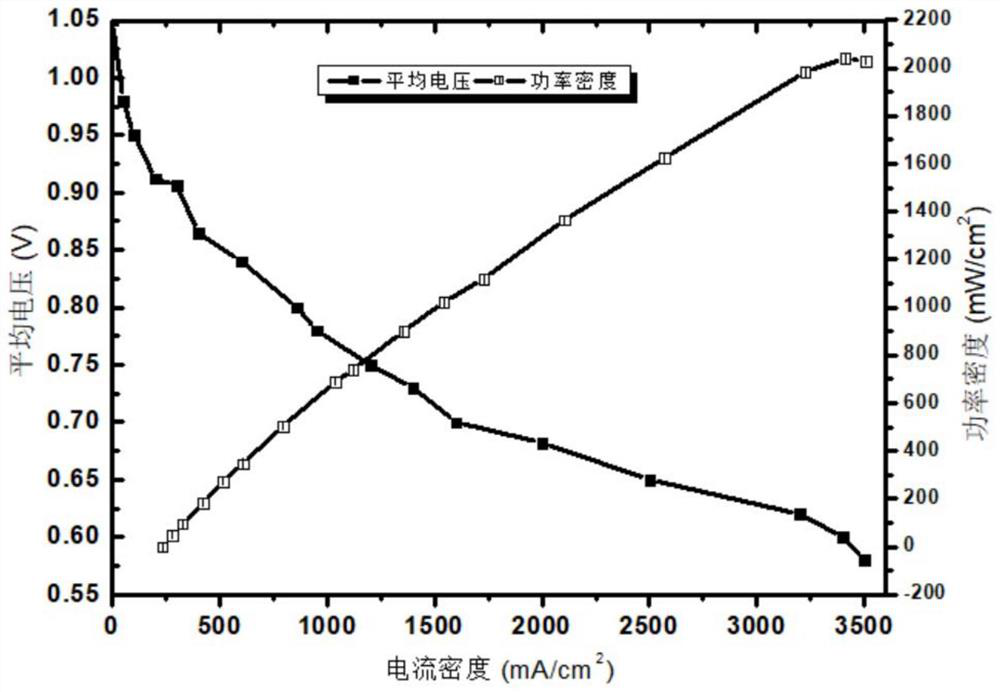

Embodiment 1

[0093] The present embodiment provides a kind of preparation method of catalytic slurry:

[0094] (1) Preparation of component A:

[0095] a. In the stirring tank, add commercialized Pt / C catalyst (the massfraction of Pt in the Pt / C catalyst is 60%) 0.12g, and add 1g deionized water stabilizer, the commercialized Pt / C catalyst is all moistened Wet and ultrasonically mix for 10 minutes;

[0096] b. Add 44g ethanol and 55g isopropanol mixed solvent, mix and stir for 18min;

[0097] c. Add 1.2 g of binder (5% Nafion resin solution), stir for 45 minutes with a high-speed emulsifying shear, and pass compressed air with a small flow rate above the liquid to obtain component A.

[0098] (2) Preparation of component B:

[0099] a. In the stirring tank, add commercialization Pt-Co / C catalyst (the mass percentage composition of Pt is 48% in the Pt-Co / C catalyst, the mass percentage composition of Co is 3%) 0.5g, and add 0.5 g deionized water stabilizer to fully wet the commercial Pt...

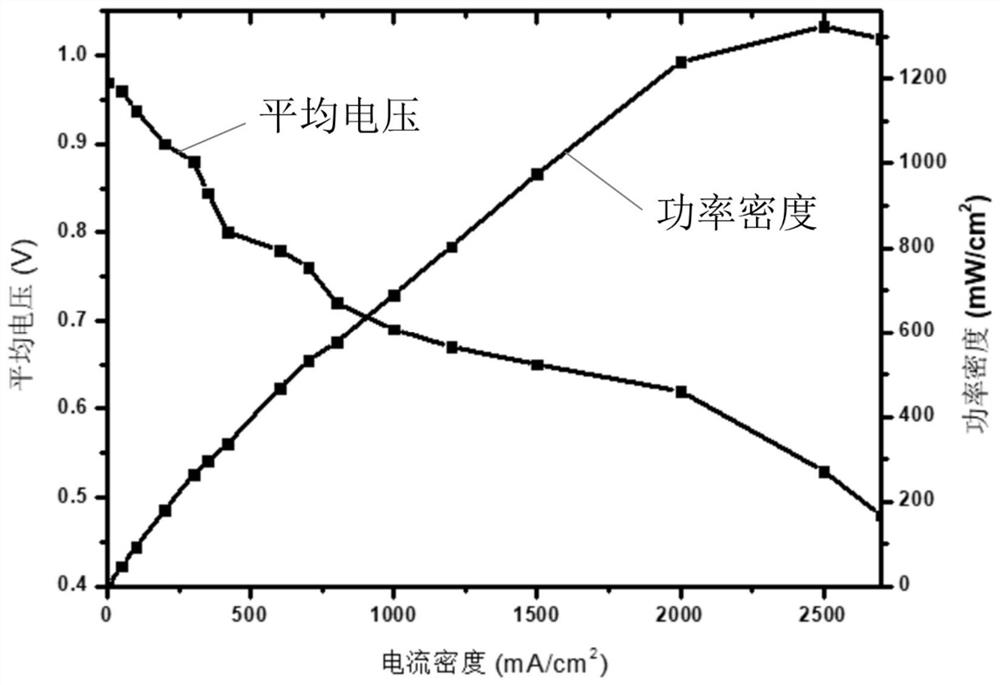

Embodiment 2

[0145] The present embodiment provides a kind of preparation method of catalytic slurry:

[0146] (1) Preparation of component A:

[0147] a. In the stirring tank, add commercialized Pt / C catalyst (the mass fraction of Pt in the Pt / C catalyst is 70%) 0.5g, and add 1.0g deionized water stabilizer, all commercialized Pt / C catalyst Wet and sonicate for 15 minutes;

[0148] b. Add 55g of ethanol and 38g of isopropanol mixed solvent, 1.5g of cerium oxide and mix and stir for 30min;

[0149] c. Add 1.0 g of binder (5% Nafion resin solution), stir with a high-speed emulsifying shearer for 70 minutes, and pass compressed air with a small flow rate above the liquid to obtain component A.

[0150] (2) Preparation of component B:

[0151] a. In the stirring tank, add commercialization Pt-Co / C catalyst (the mass percentage composition of Pt is 46% in the Pt-Co / C catalyst, the mass percentage composition of Co is 4%) 0.75g, and add 0.4 g deionized water stabilizer to fully wet the comm...

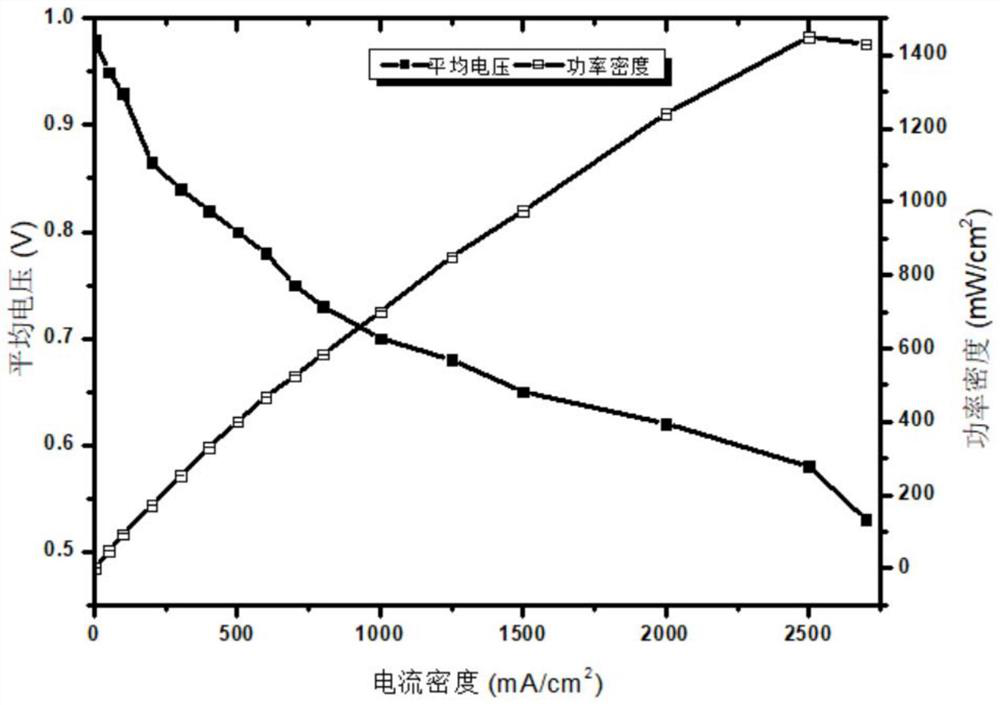

Embodiment 3

[0163] The present embodiment provides a kind of preparation method of catalytic slurry:

[0164] (1) Preparation of component A:

[0165] a. In the stirring tank, add commercialized Pt / C catalyst (the mass fraction of Pt in the Pt / C catalyst is 60%) 0.5g, and add 0.6g deionized water stabilizer, and commercialized Pt / C catalyst is all Wet and sonicate for 5 minutes;

[0166] b. Add 40g ethanol and 50g isopropanol mixed solvent, 1.5g rubidium oxide and mix and stir for 10min;

[0167] c. Add 0.9 g of binder (5% Nafion resin solution), stir for 45 min with a high-speed emulsifying shear, and pass a small flow of compressed air above the liquid to obtain component A.

[0168] (2) Preparation of component B:

[0169] a. In the stirring tank, add commercialized Pt-Cu / C catalyst (the mass percentage composition of Pt in the Pt-Co / C catalyst is 48%, the mass percentage composition of Co is 3%) 0.6g, and add 0.9g deionized water stabilizer wets the commercial Pt-Co / C catalyst com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com