A test device for realizing multiple composite crack propagation and using method

A crack propagation and test device technology, which is applied in the field of test devices to realize multiple compound crack growth, and can solve problems such as experimental measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions of the present invention will be clearly and completely described below with reference to the specific embodiments of the present invention and the corresponding drawings. The technical solutions provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

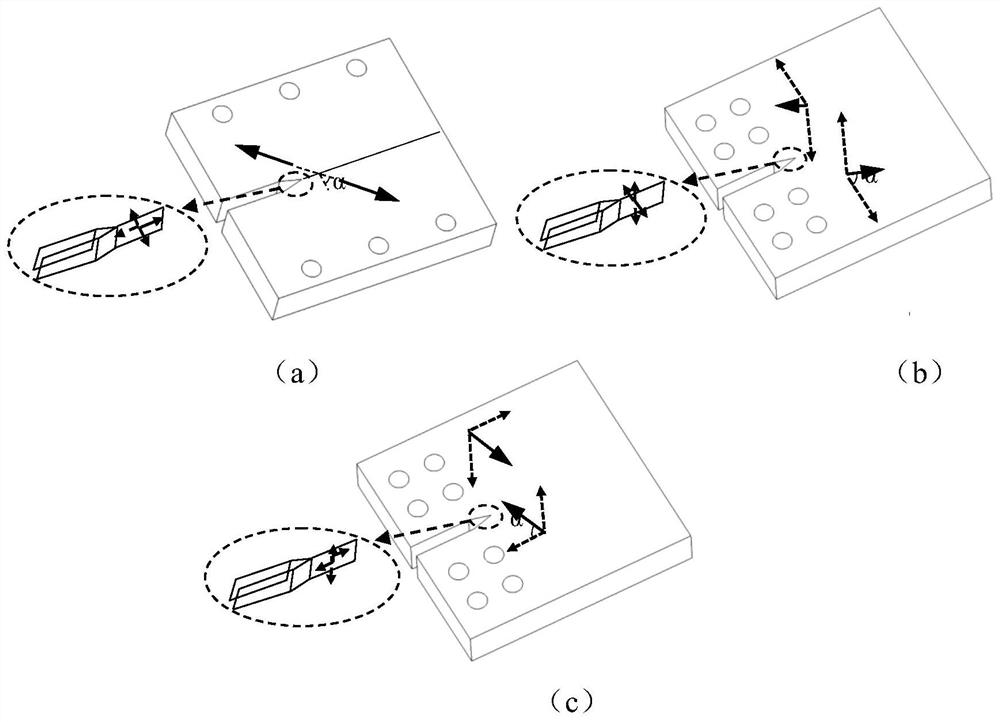

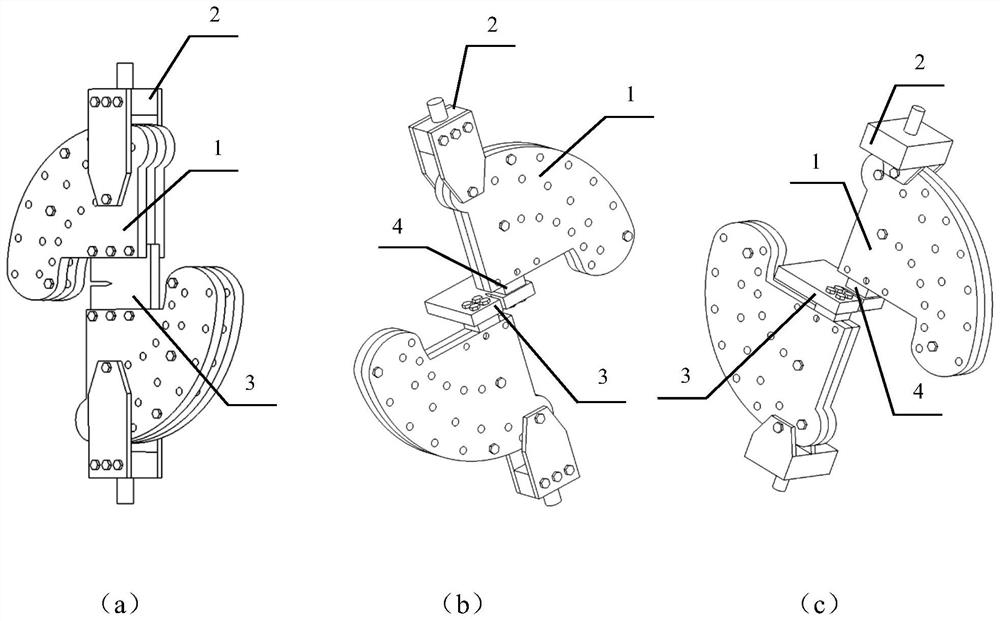

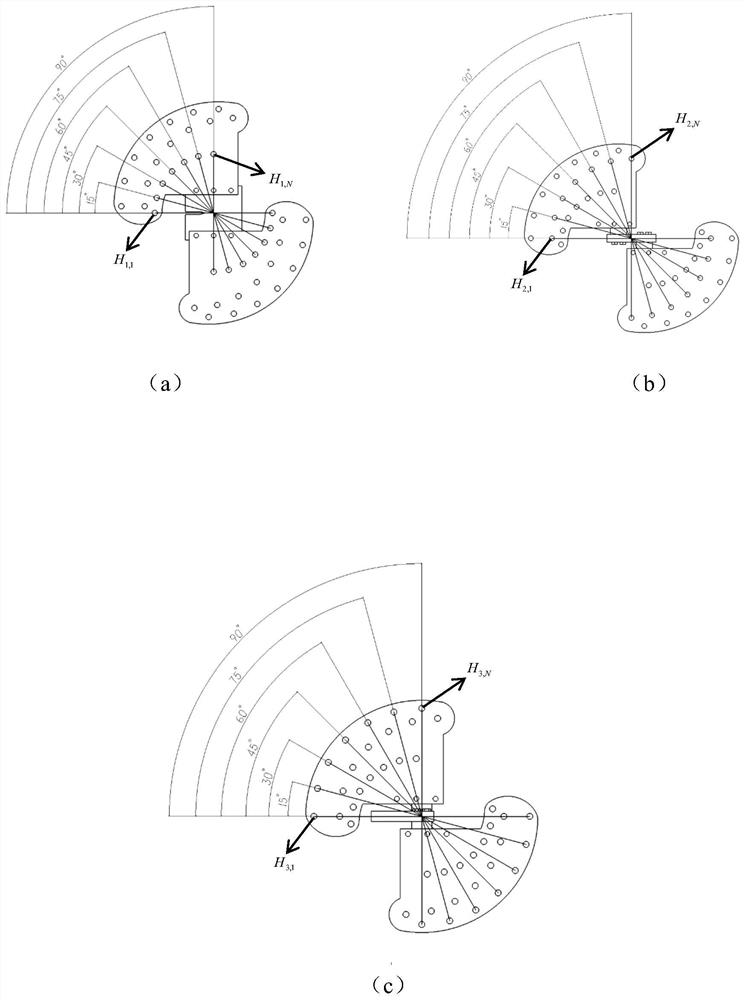

[0034] According to the embodiments of the present invention, a test device and method for realizing multiple composite crack propagation are provided, which are used for testing composite crack propagation behavior of materials. The composite crack growth experiment uses the same size sample, figure 1 (a) is the sample used for type I / II loading, which is subjected to tension and plane shear during the experiment; figure 1 (b) is the sample used for type I / III loading, which is subjected to tensile and inverse plane shea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com