A sealed and pressure-resistant device installed with a constant-volume bomb injector

A technology of pressure-resistant devices and fuel injectors, which is applied in the direction of measuring devices, testing of machines/structural components, instruments, etc., can solve problems such as unstable installation and difficult sealing of fuel injectors, and achieve convenient and fast installation and strong integrity , adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

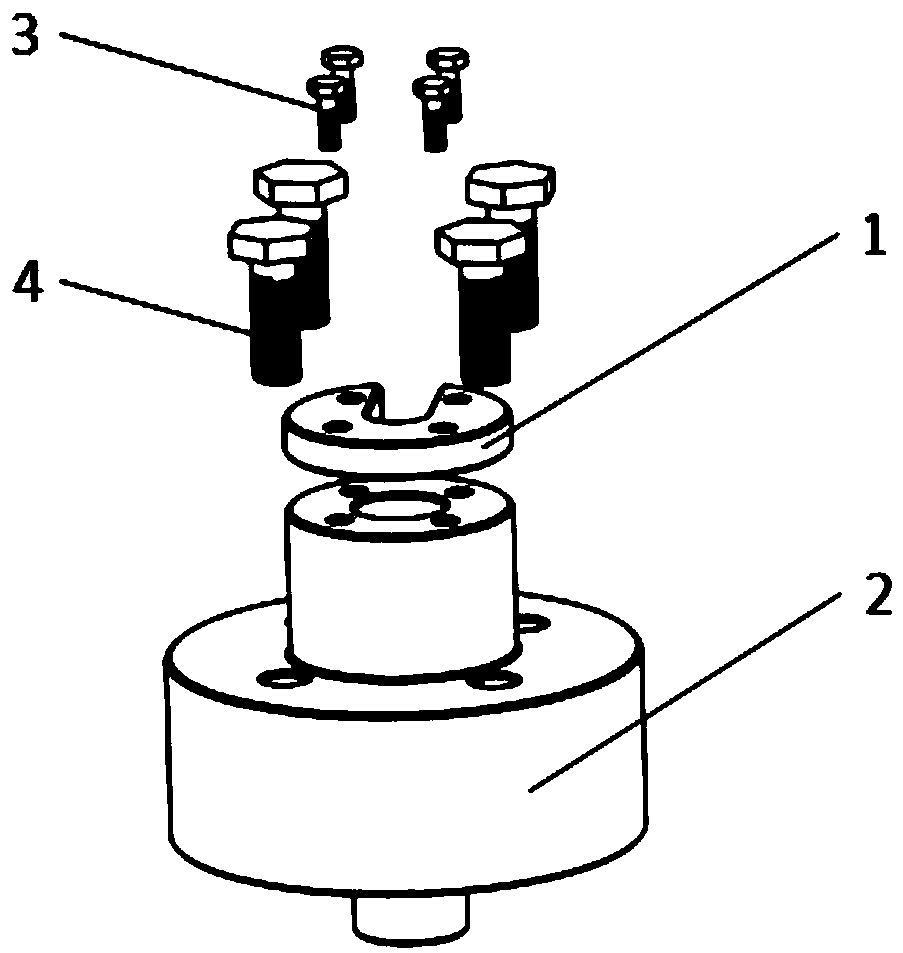

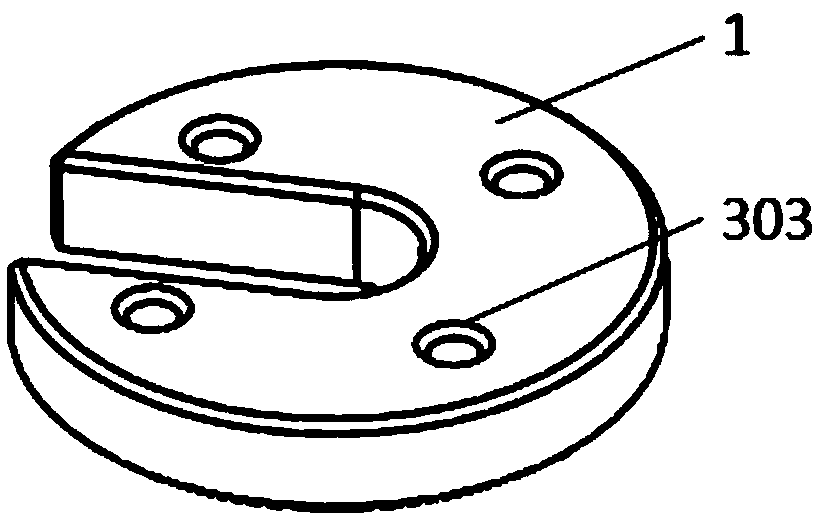

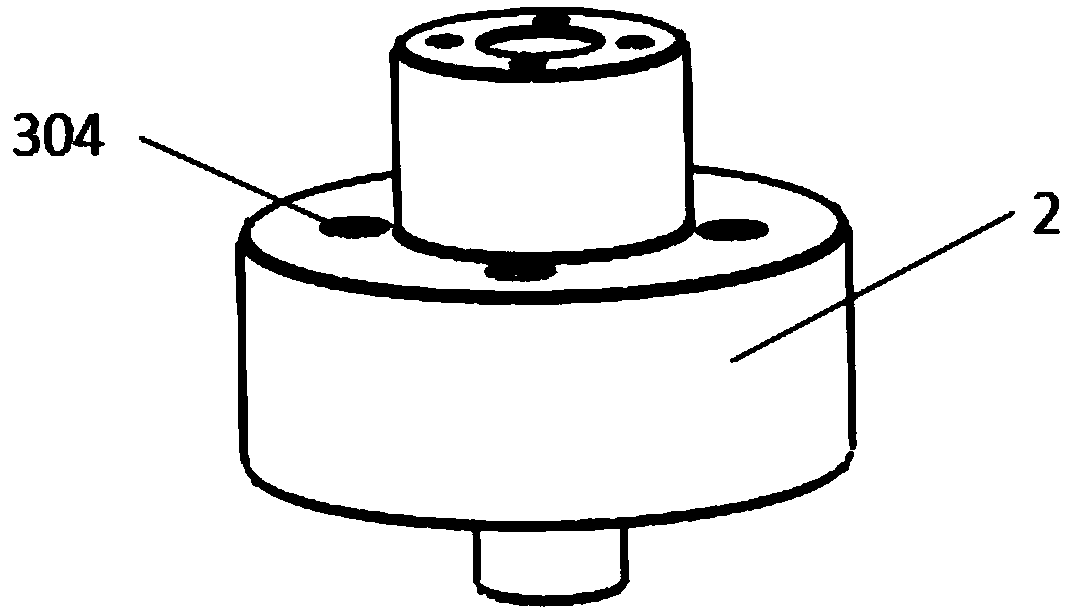

[0020] combine Figure 1 to Figure 4 , the present invention includes a fuel injector mounting base 2, a fuel injector gland 1 and bolts 3, 4; the fuel injector mounting base is an integral structure, a fuel injector for fixed volume Homemade parts such as image 3 , 4 As shown, the fuel injector installation base 2 is divided into upper, middle and lower layers, which are respectively cylinders with different diameters and penetrate the middle up and down and have a through hole for installing the fuel injector. The inner cavity profile of the through hole It is consistent with the characteristics of the outer wall of the injector. At the same time, the cylinder at the bottom of the injector installation base is well fitted in the installation hole of the injector of the constant volume bomb. Movement under the influence of high-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com