Range hood with movable fan and control method of range hood

A technology of a range hood and a control method, which is applied in the directions of removing oil fume, heating method, and household heating, etc., can solve the problems of unbalanced oil fume concentration, high energy consumption, and inability to maximize the use of fans, and achieve rapid extraction of oil fume. , improve work performance, reduce the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

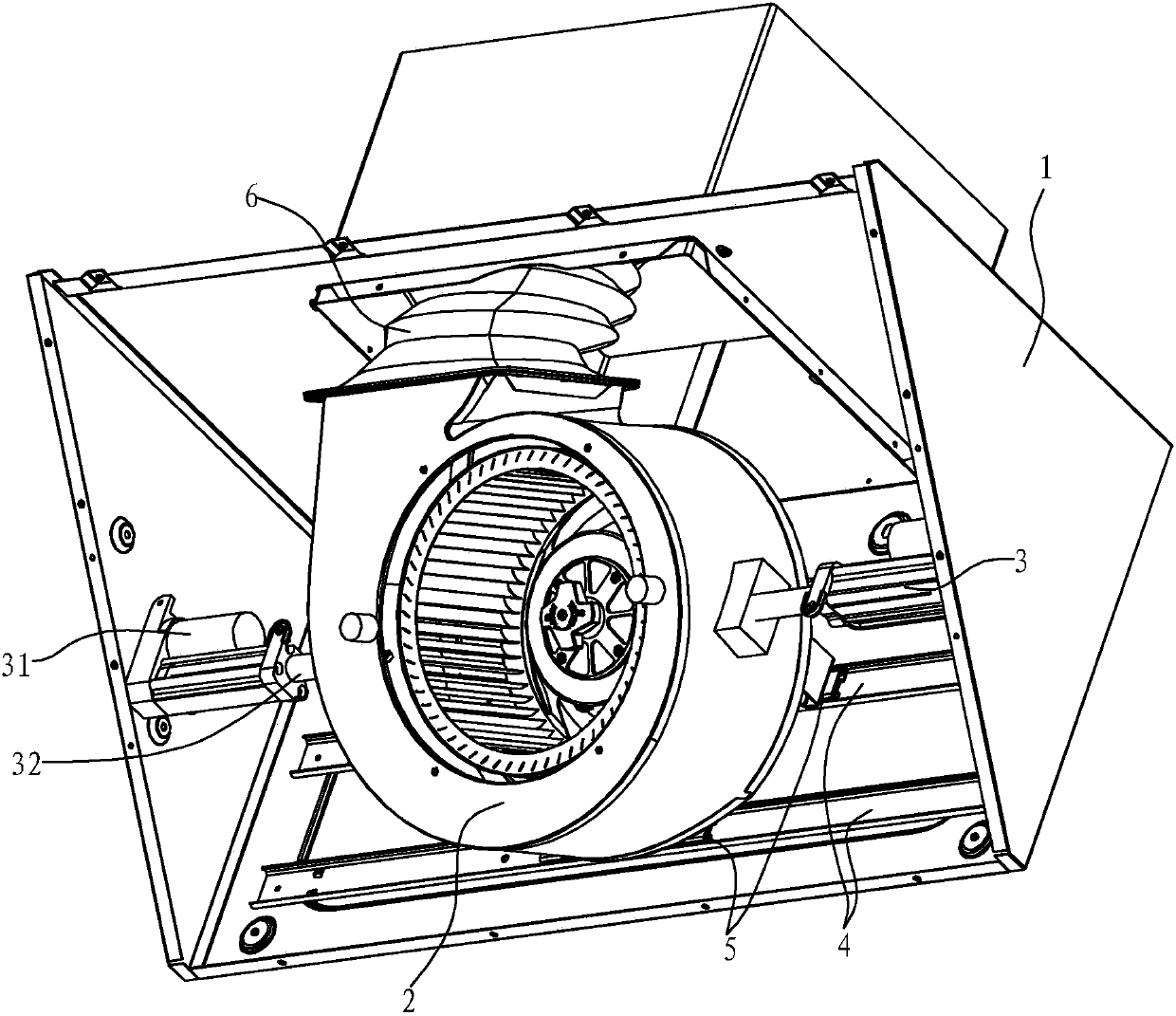

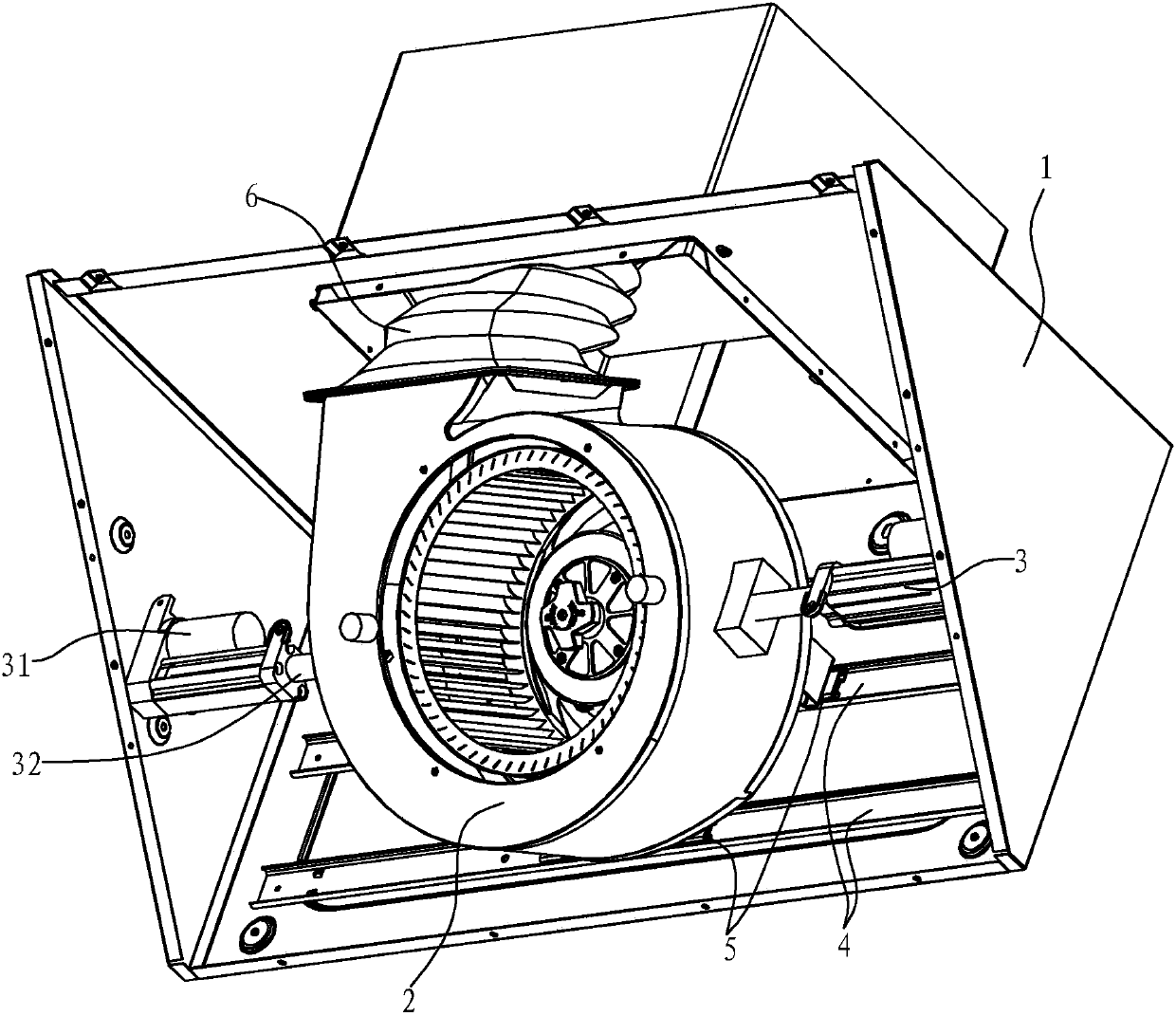

[0030] Such as figure 1 As shown, the range hood with a displaceable fan in this embodiment includes a casing 1 , a fan 2 and a driving mechanism 3 , and both the fan 2 and the driving mechanism 3 are arranged in the casing 1 .

[0031] According to the positioning and needs of range hood products, the fan 2 can also be driven manually. The specific support structure is set according to the space in the casing 1. An operating handle is reserved outside the casing 1, and then the handle can be pushed. The way to drive the fan 2 to move.

[0032] At the same time, the moving mode of the fan 2 can also be adaptively set according to the specific positions of the cooking holes on the cooking range, so as to ensure that the fan 2 can move to the top of each cooking hole, so as to facilitate and better exert the working performance of the fan 2 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com