Piston for breaking hammer and manufacturing method thereof

A manufacturing method and breaking hammer technology, applied in the directions of pistons, manufacturing tools, cylindrical pistons, etc., can solve the problems of poor anti-friction performance, decreased hardness of the piston core, and piston strain, so as to achieve less wear and less maintenance. cost, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

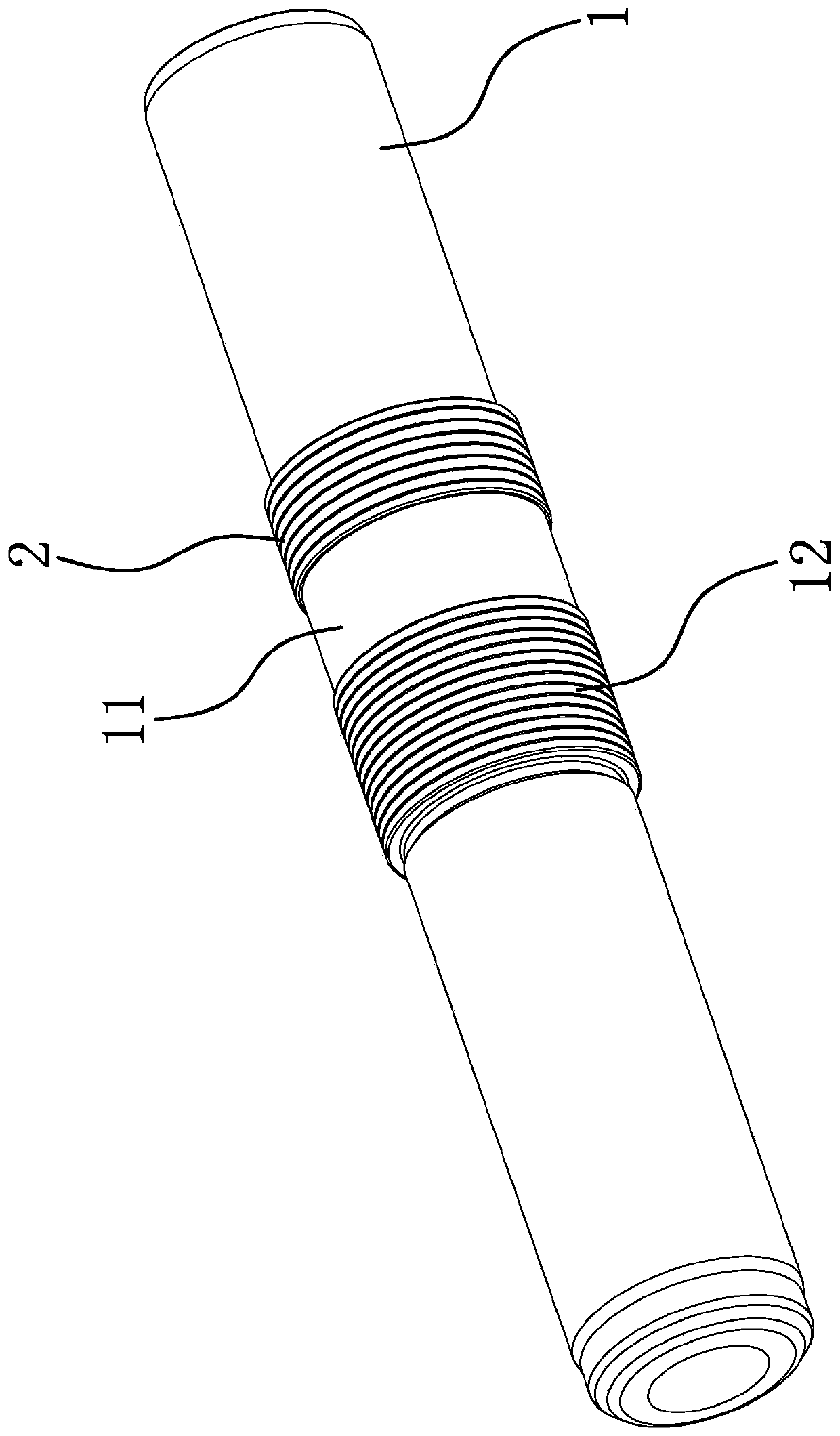

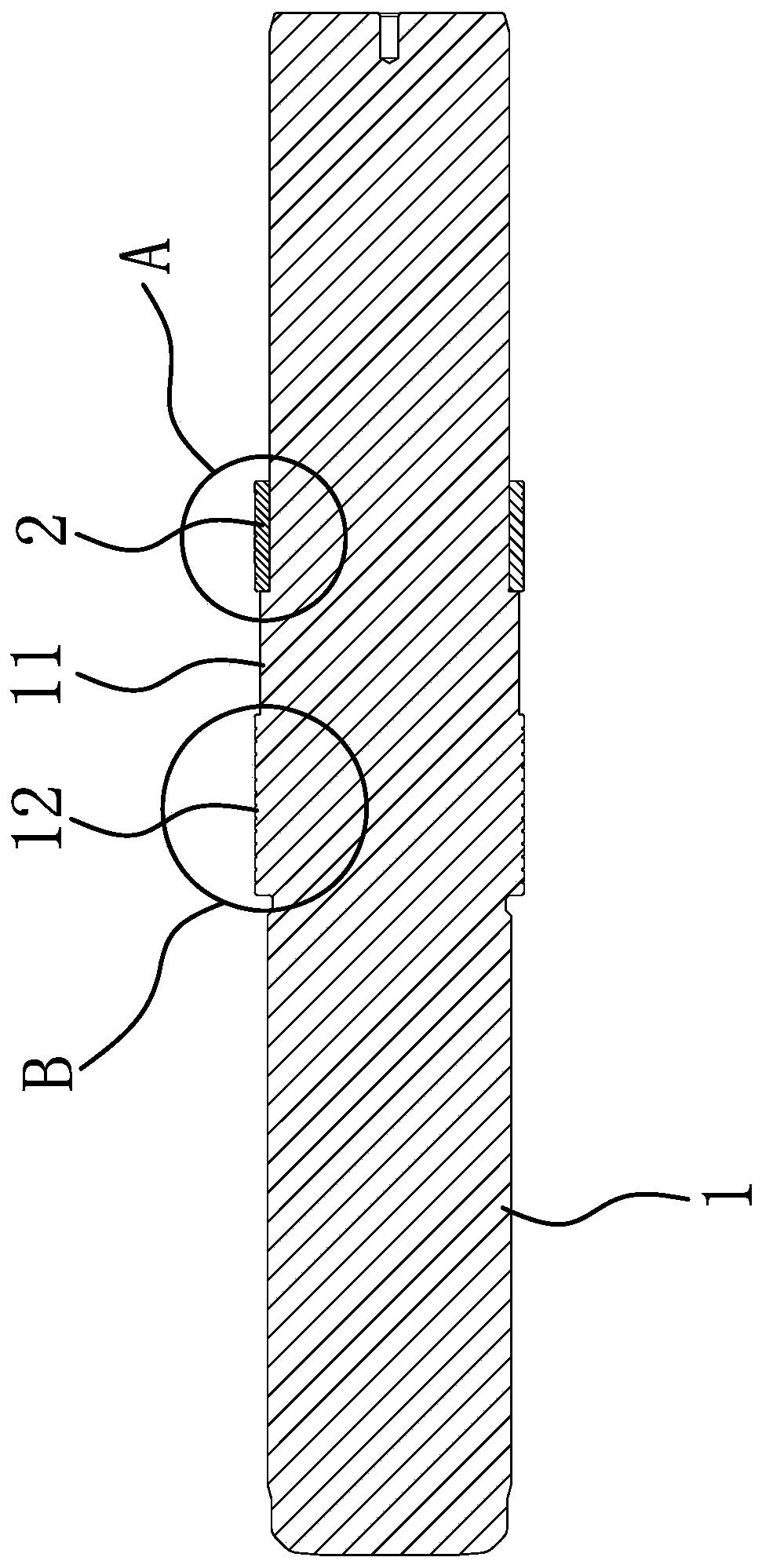

[0031] Such as Figure 1 to Figure 4 as shown, The piston for the breaking hammer includes a piston main body 1. The outer peripheral surface of the piston main body 1 has an annular positioning boss 11. The piston main body 1 has a front boss 12 on the front side of the positioning boss 11. The piston main body 1 1. The front boss 12 and the positioning boss 11 are integrally formed. The outer diameter of the front boss 12 is greater than the outer diameter of the positioning boss 11. The outer edges of the front and rear end faces of the front boss 12 are provided with chamfers 2 12a. The boss 12 is located in the middle of the piston body 1 .

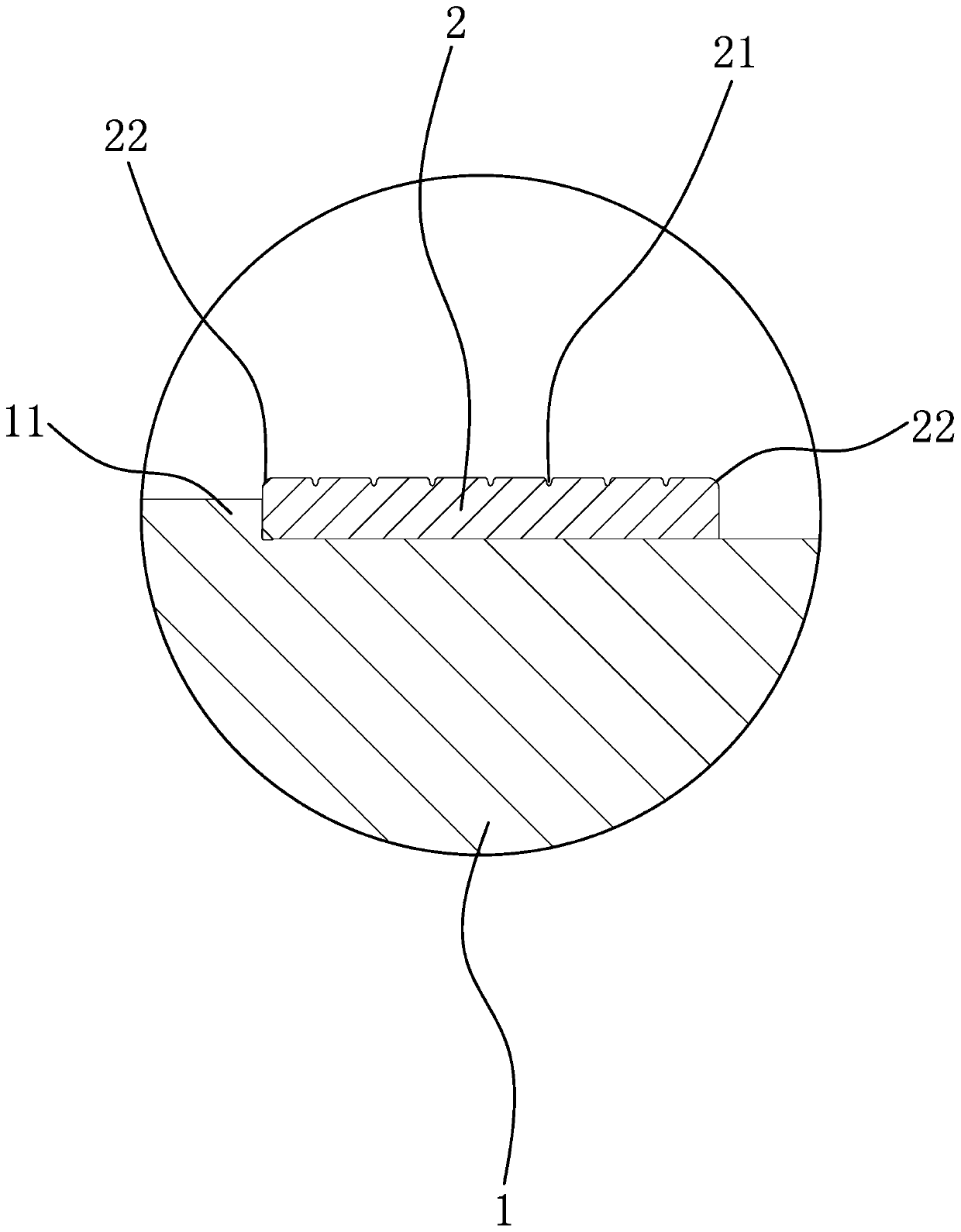

[0032] Such as Figure 1 to Figure 4 as shown, The piston main body 1 is provided with a wear-resistant sleeve 2 on the rear side of the positioning boss 11, and the wear-resistant sleeve 2 is in interference fit with the piston main body 1. The outer diameter of the wear-resistant sleeve 2 is the same as that of the front boss ...

Embodiment 2

[0041] The content of this embodiment is basically the same as that of the above-mentioned embodiment 1, the difference is that: the front side of the positioning boss 11 is provided with a wear-resistant sleeve 2, and the front boss 12 is arranged on the rear side of the positioning boss 11, which is equivalent to a wear-resistant sleeve 2 and front boss 12 interchange positions, other structures remain unchanged.

Embodiment 3

[0043] The content of this embodiment is basically the same as that of the above-mentioned embodiment 1, the difference is that: the front and rear sides of the positioning boss 11 are provided with wear-resistant sleeves 2 , and one end surface of the wear-resistant sleeve 2 abuts against the end surface of the positioning boss 11 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com