Premixed propellant injector with integrated ignition and tempering prevention functions

A propellant and anti-backfire technology, which is applied in the direction of jet propulsion devices, machines/engines, rocket engine devices, etc., can solve problems such as the inability to use anti-backfire measures, and achieve the effects of preventing backfire, uniform injection and ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

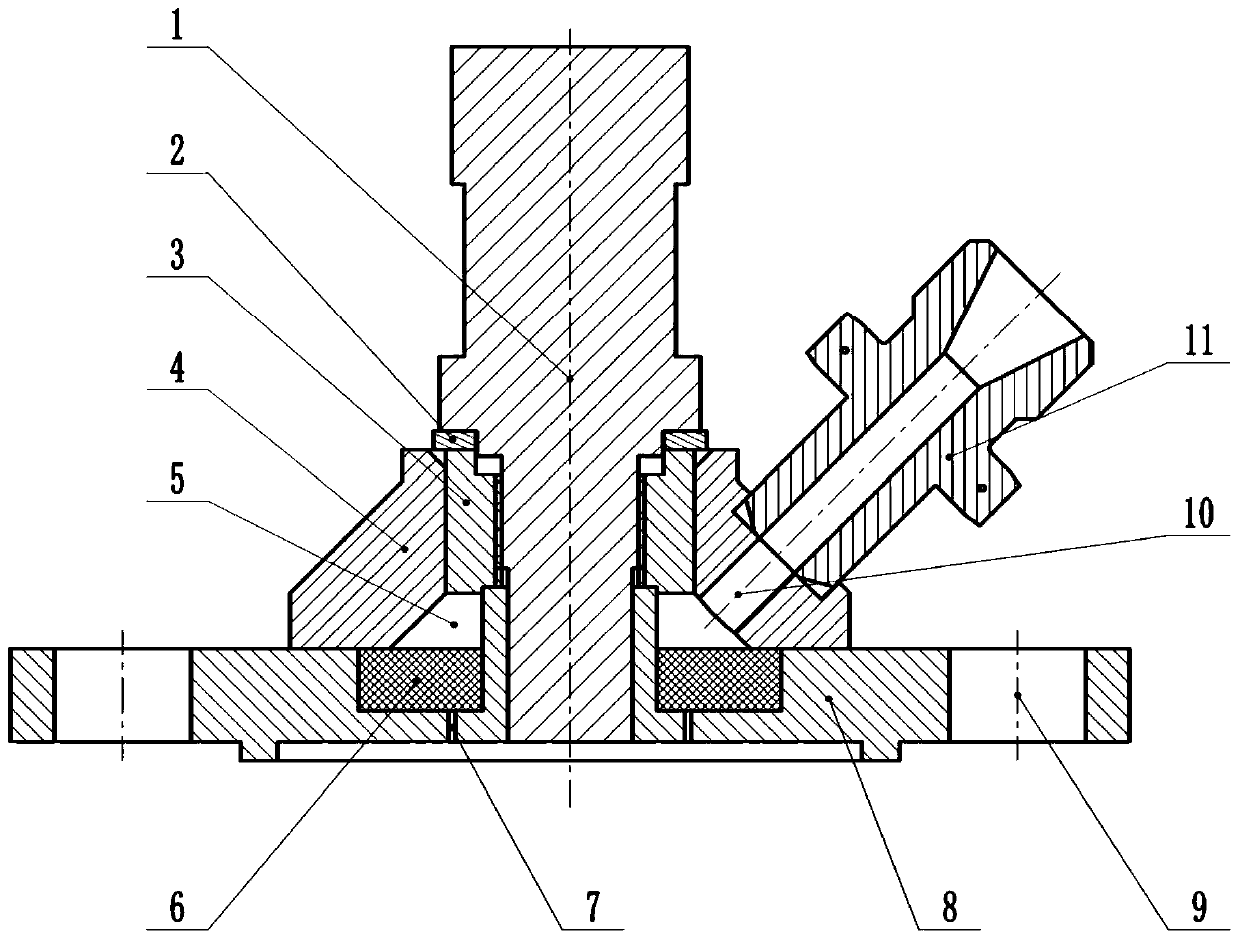

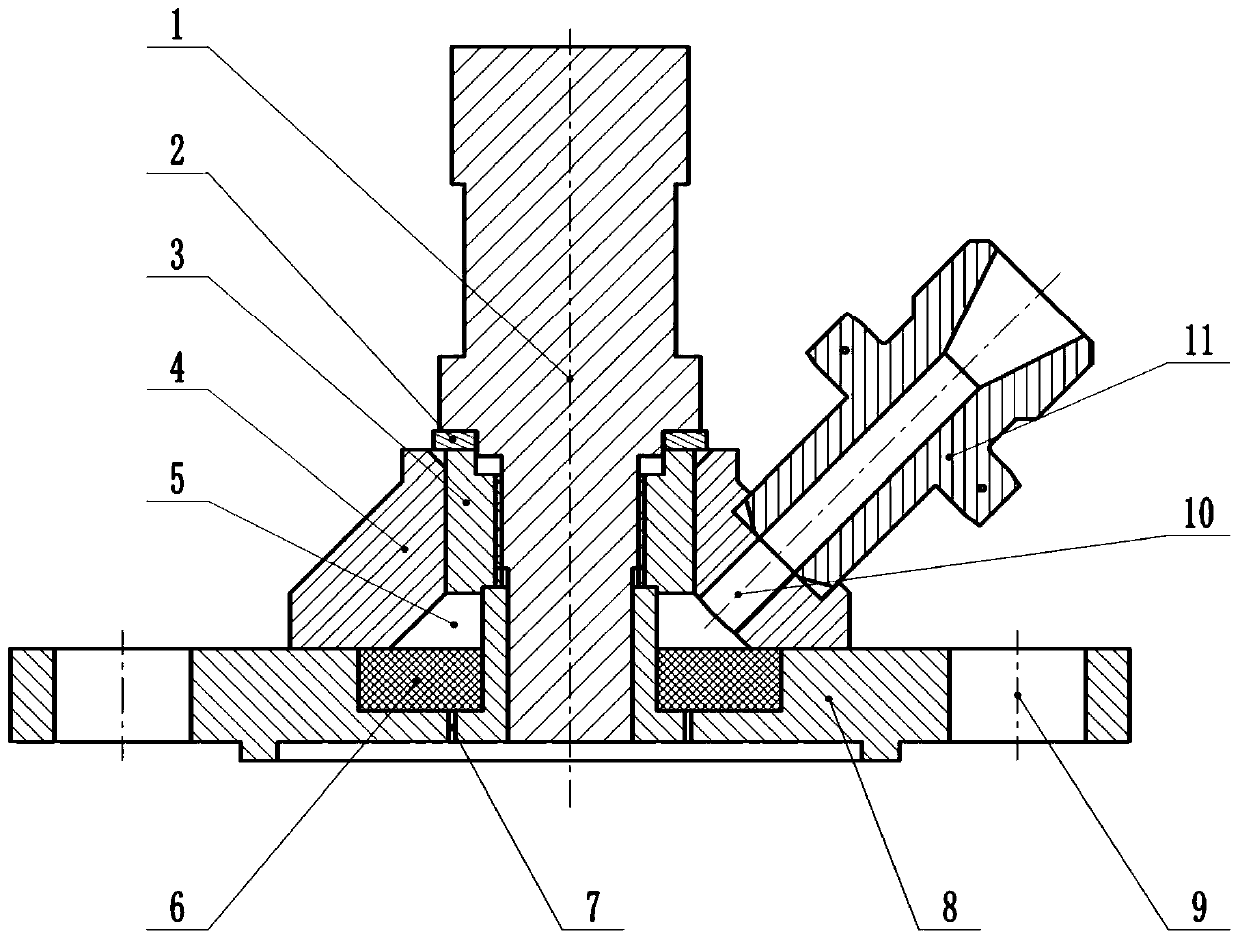

[0021] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] The present invention provides a premixed propellant injector with integrated ignition and anti-backfire functions. Its working principle is as follows: the premixed propellant enters the liquid collection chamber 5 along the propellant inlet conduit 11, and passes through the injection body of porous material. 6 and the direct-current injection hole 7 are uniformly sprayed and atomized, and a low-velocity recirculation zone is formed at the ignition end surface of the electric spark plug 1, and the ignition and stable combustion of the propellant are realized by the electric spark plug 1, and the micron-scale flow channel of the porous material injection body 6 It can effectively prevent the combustion flame from backfiring.

[0023] like figure 1 As shown, the premixed propellant injector with integrated i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com