Method for Fracturing Coalbed Gas Reservoir Using Nitrogen Foam Fracturing Fluid

A technology of nitrogen foam and fracturing fluid, which is applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., can solve the problems of inability to effectively control the size and shape of fractures, high equipment requirements, and low safety, and achieve Easy to complex crack network, high construction safety, simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

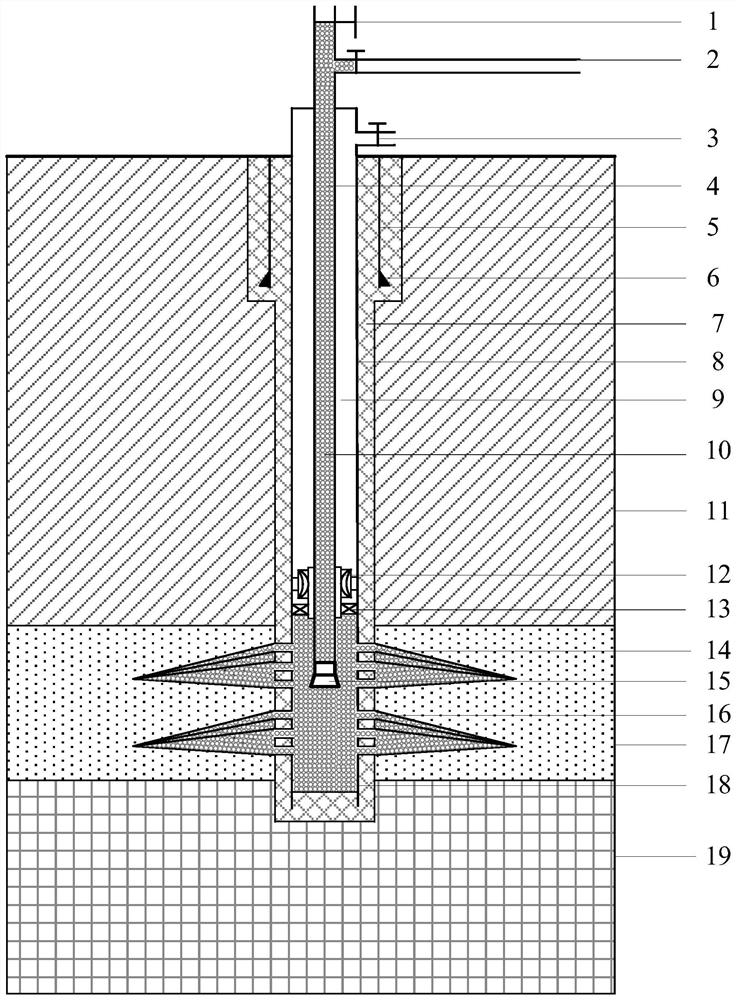

[0023] like figure 1 As shown, the coalbed methane well fractured by nitrogen foam fracturing fluid includes: fracturing operation string 4, completion casing 8, packer 13, hydraulic anchor 12 and sliding sleeve 15; completion casing 8 from top to bottom The bottom passes through the overlying formation 11 and the coalbed methane reservoir 17 in turn until the upper part of the underlying formation 19; the oil casing annular valve 3 is installed on the top of the completion casing 8, which is used for injection and discharge of the annular pressure balance fluid; There is an artificial well bottom 18 at the bottom of the pipe 8, and there is a perforation 16 on the well completion casing in the coalbed methane reservoir 17, and the perforation is used to pump nitrogen foam fracturing fluid 10 into the coalbed methane reservoir 17 and provide a channel for coalbed methane extraction; complete There is a concentric technical casing 5 on the upper part of the well casing, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com