Vehicle-mounted traffic cone automatic laying device

A traffic cone and vehicle-mounted technology, which is applied in the field of vehicle-mounted traffic cone automatic deployment devices, can solve problems such as low work efficiency, inconvenient operation, and slow operation speed, and achieve the effects of easy promotion, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

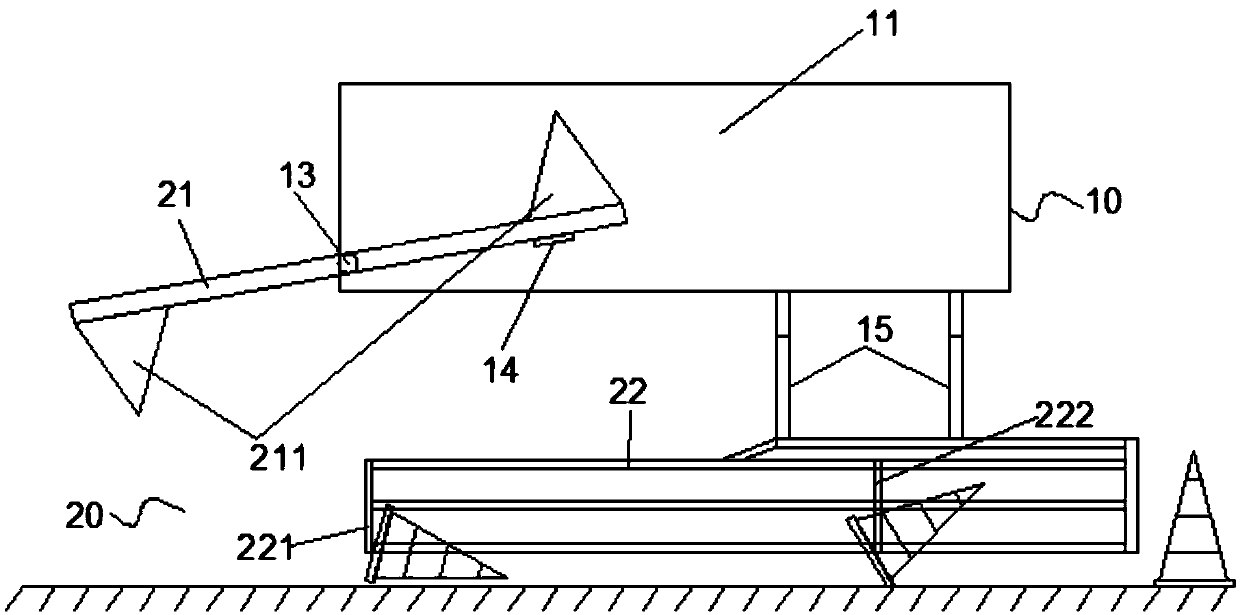

[0021] see Figure 1~2 , a vehicle-mounted traffic cone automatic deployment device, comprising a structure panel 10, a traffic cone deployment mechanism 20; the structure panel includes a first flat plate 11 and a second flat plate 12 perpendicular to each other; the traffic cone deployment The mechanism 20 is fixedly connected to the first flat plate 11; the traffic cone deployment mechanism includes a turning plate 21 and a guide frame 22; a pair of conical protrusions 211 are provided on the surface of the turning plate at both ends, and the tapered The protrusions 211 are respectively located on the plate surface of the opposite side of the turning lever 21, and the side of the turning plate 21 in the middle is connected with the first flat plate 11 through a rotating shaft 13, and the turning 21 plate can be carried out with the rotating shaft 13 as the center. Rotation; the first flat plate 11 is provided with a preparatory position shrapnel 14 that limits the idling of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com