Cell micro-scalpel based on optical fiber optical hand, and manufacture method for cell micro-scalpel

A micro-scalpel and low-light technology, applied in the field of single-cell manipulation, can solve the problems of low flexibility and large volume of the spatial light system, and achieve the effect of precise cell surgical positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: The fiber-optic low-light hand has a powerful cell posture adjustment function.

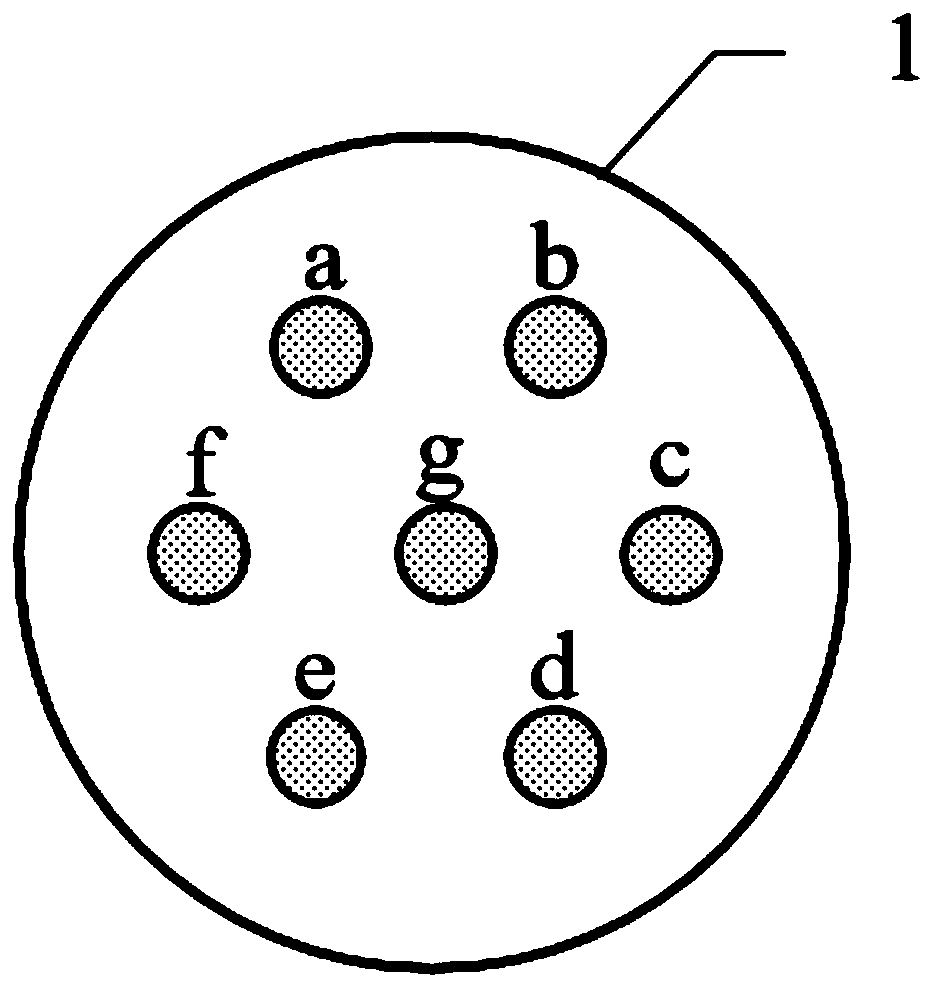

[0050] This embodiment adopts seven-core optical fiber to describe the present invention in detail, as figure 1 What is shown is a schematic view of the end face of the seven-core optical fiber 1 . The optical fiber has a central core and six peripheral cores distributed coaxially and annularly. In order to reflect and converge the captured light transmitted in the surrounding fiber core to form a trapping potential well, it is necessary to prepare a reflective frustum conical structure at the fiber end by precision grinding, such as figure 2 As shown, the frustoconical structure can be as figure 2 (a) shows the frustum of conical structure 1-1. Of course, in order to make the beam focus better and make the cell capture effect more stable, you can figure 2 The frustum structure in (a) is optimized to form an arc-shaped reflective frustum structure 1-2, such as figure 2 ...

Embodiment 2

[0053] Example 2: Cell high-precision, minimally invasive surgery function.

[0054] Such as Figure 5 As shown in (a), the single cell 9 is stably captured by the low-light hand of the seven-core optical fiber and its posture is adjusted so that the site to be operated on of the cell 9 faces the end face of the optical fiber. Figure 5 (b) is a cross-sectional view along the fiber axis. In addition to the truncated conical structure 1-1 that reflects and captures the beam, the fiber end of the seven-core fiber is also etched with a 10um×10um×10um concave in the middle of the fiber end face. Groove 13, groove 13 has microsphere lens 12 adhered with low refractive index glue. Figure 5 (c) is an enlarged view of the groove 13. The light beam output by the middle core of the seven-core optical fiber 1 is compressed by the microsphere lens 12, and can form a needle-shaped photon jet 14 in the axial direction outside the end face of the optical fiber, that is, this patent The Mi...

Embodiment 3

[0066] Example 3: The preparation method of cell micro-surgical knife based on optical fiber micro-light hand.

[0067] Step 1: Take a multi-core optical fiber 1, cut it flat, and use a femtosecond laser to etch a groove 13 on its end face, with a size of 10um×10um×10um;

[0068] Step 2: place a microsphere lens in the groove, and use low refractive index glue to cure the microsphere lens 12 in the center of the groove 13;

[0069] Step 3: Precisely grind and polish the end face, remove the excess adhesive layer 15, and make the end face of the multi-core optical fiber smooth;

[0070] Step 4: Precisely grind the end of the optical fiber to prepare a symmetrical reflective frusto-conical structure 1-1, polish it, clean it ultrasonically, and dry it with nitrogen gas before use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com