Enzyme-modified biomass wood adhesive and preparation method thereof

A wood adhesive and biomass technology, applied in the field of wood adhesives, can solve the problems of high production cost, poor process applicability, uncompetitive products, etc., achieve important economic and social benefits, increase bonding strength and water resistance, solve the The effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

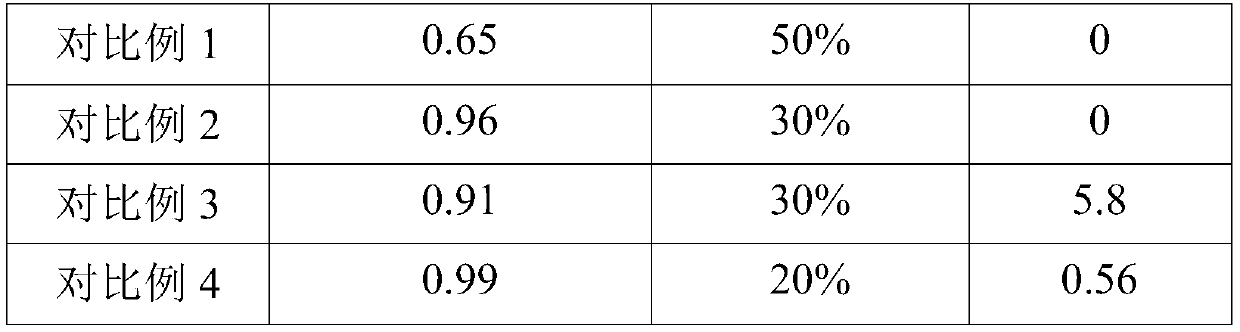

Examples

Embodiment 1

[0023] An enzyme-modified biomass wood adhesive of the present invention comprises the following components in mass percent, per 100 grams: 4% soybean protein isolate, 0.1% sodium hydroxide, 0.001% tyrosinase, and 0.4% glucosamine sulfate %, hydroxymethyl cellulose 2%, and the balance is water.

[0024] The preparation method of an enzyme-modified biomass wood adhesive of the present invention comprises separately taking soybean protein isolate, glucosamine sulfate, hydroxymethyl cellulose and water, dissolving the soybean protein isolate in water, and taking sodium hydroxide to adjust the pH of the solution The value is 7, then stir at 50°C for 2h to form a vegetable protein solution, then add glucosamine sulfate and tyrosinase, stir overnight at 37°C, and then disperse hydroxymethylcellulose evenly in the solution, ultrasonic working time 5s, intermittent time 5s, total time 200s, power 350W, temperature 4°C, volume 100mL. After the pressure is 35MPa (5000psi), the volume i...

Embodiment 2

[0026] An enzyme-modified biomass wood adhesive of the present invention comprises the following components in mass percent, every 100 grams contains: whey protein 8%, potassium hydroxide 0.3%, laccase 0.004%, glucosamine hydrochloride 1.0%, Hydroxyethyl cellulose 2%, the balance is water.

[0027] The preparation method of an enzyme-modified biomass wood adhesive in the present invention comprises taking whey protein, hydroxyethyl cellulose and water respectively, and uniformly dispersing the whey protein and hydroxyethyl cellulose in water, and the ultrasonic working time is 5s , the intermittent time is 5s, the total time is 200s, the power is 350W, the temperature is 4°C, and the volume is 100mL. Take potassium hydroxide to adjust the pH value of the solution to 9, stir at 50°C for 2 hours to form a mixed solution of vegetable protein and cellulose, then add laccase and glucosamine hydrochloride, stir at 37°C for 3 hours, ), the volume is 100mL, and the wood adhesive is o...

Embodiment 3

[0029] An enzyme-modified biomass wood adhesive of the present invention comprises the following components in mass percentages, and every 100 grams contains: a mixture of 12% soybean protein isolate and millet gluten in a mass ratio of 20:1, hydrogenated Calcium 0.8%, peroxidase 0.005%, glucosamine sulfate 1.5%, dextran 3%, and the balance is water.

[0030] The preparation method of an enzyme-modified biomass wood adhesive of the present invention comprises taking millet gluten protein, glucosamine sulfate, dextran and water respectively, dissolving the mixture of soybean protein and millet gluten protein in water, taking hydrogen oxidation Adjust the pH value of the calcium solution to 11, then stir at 50°C for 2 hours to form a vegetable protein solution, then add peroxidase and glucosamine sulfate, stir overnight at 37°C, then disperse the dextran in the solution evenly, and ultrasonically The working time is 5s, the intermittent time is 5s, the total time is 200s, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com