A kind of alkali slag magnesium oxychloride cement and its preparation method and application

A technology of magnesium oxychloride cement and alkali slag, which is applied in the field of alkali slag magnesium oxychloride cement and its preparation, can solve the problems that alkali slag has not been effectively treated, large-scale industrial production cannot be produced, and product quality is unstable. Strength, excellent fire resistance, and the effect of good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

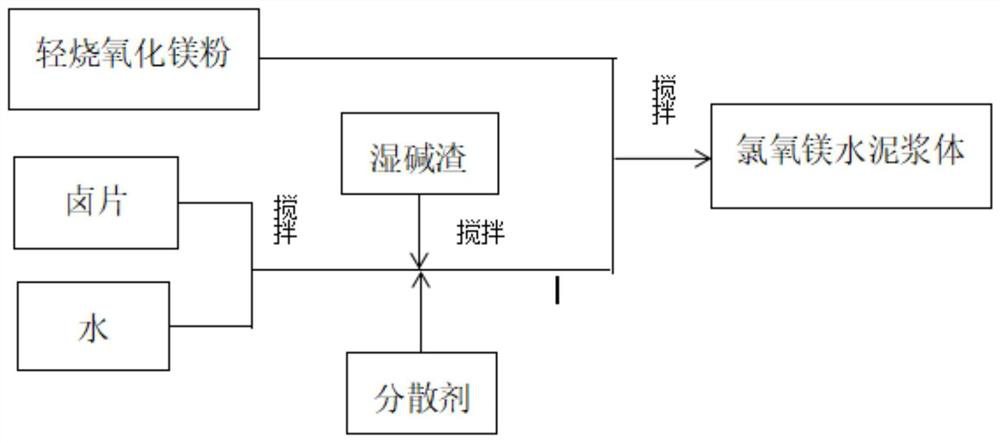

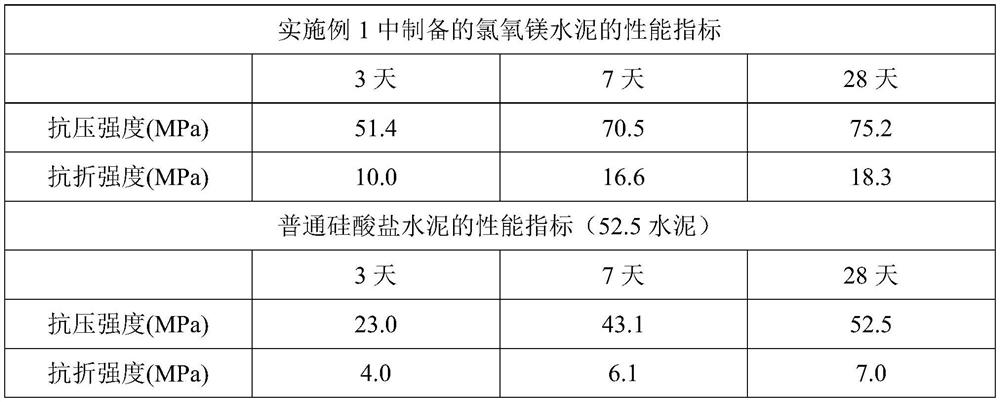

[0031] According to attached figure 1 Technological process, prepare the magnesium oxychloride cement with soda making waste slag as admixture, take the following raw materials by weight according to the proportion: 90 parts of light-burned magnesium oxide powder, halogen sheet (main component MgCl 2 ·6H 2 O) 90 parts, water 55 parts, wet alkali slag 25 parts, sodium hexaphosphate metaphosphate (dispersant) 1 part.

[0032] Specifically include the following steps:

[0033] S1. dissolving the brine slices in water to form a brine solution;

[0034] S2. adding the dispersant into the wet alkali slag;

[0035] S3. Mix the brine solution in step S1 with the wet alkali slag mixed in step S2;

[0036] S4. Add the burned magnesia powder to the wet alkali slag mixed in step S3, and stir evenly to form cement slurry;

[0037] S5. Cast the cement slurry in step S4 into a mold, demould after curing at room temperature, and continue curing to obtain the magnesium oxychloride cement....

Embodiment 2

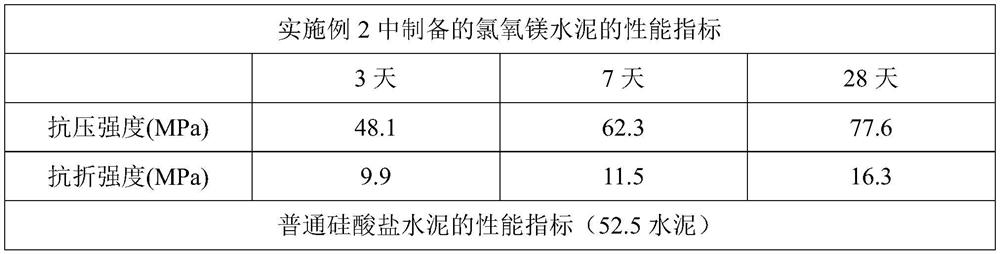

[0043] According to attached figure 1 Technological process, prepare the magnesium oxychloride cement with soda making waste slag as admixture, take the following raw materials by weight in proportion: 100 parts of lightly burned magnesium oxide powder, halogen sheet (main component MgCl 2 ·6H 2 O) 90 parts, water 50 parts, wet alkali residue 30 parts, sodium dodecylbenzenesulfonate (dispersant) 1.5 parts.

[0044] Specifically include the following steps:

[0045] S1. dissolving the brine slices in water to form a brine solution;

[0046] S2. adding the dispersant into the wet alkali slag;

[0047] S3. Mix the brine solution in step S1 with the wet alkali slag mixed in step S2;

[0048] S4. Add the burned magnesia powder to the wet alkali slag mixed in step S3, and stir evenly to form cement slurry;

[0049] S5. Cast the cement slurry in step S4 into a mold, demould after curing at room temperature, and continue curing to obtain the magnesium oxychloride cement.

[0050...

Embodiment 3

[0056] According to attached figure 1 Technological process, prepare the magnesium oxychloride cement with soda making waste slag as admixture, take the following raw materials by weight according to the proportion: 98 parts of light-burned magnesium oxide powder, halogen sheet (main component MgCl 2 ·6H 2 O) 80 parts, 65 parts of water, 40 parts of wet alkali slag, 2 parts of polymerized carboxylic acid comb graft copolymer (dispersant).

[0057] Specifically include the following steps:

[0058] S1. dissolving the brine slices in water to form a brine solution;

[0059] S2. adding the dispersant into the wet alkali slag;

[0060] S3. Mix the brine solution in step S1 with the wet alkali slag mixed in step S2;

[0061] S4. Add the burned magnesia powder to the wet alkali slag mixed in step S3, and stir evenly to form cement slurry;

[0062] S5. Cast the cement slurry in step S4 into a mold, demould after curing at room temperature, and continue curing to obtain the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com