Metal cutting machine tool capable of quickly clamping

A technology of metal cutting and clamping mechanism, which is applied to the accessories of toolholders, metal processing equipment, turning equipment, etc., which can solve the problems of easily affecting the cutting of workpieces, insufficient technology, and slow clamping speed, so as to reduce defective cutting products High efficiency, fast clamping speed and stable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

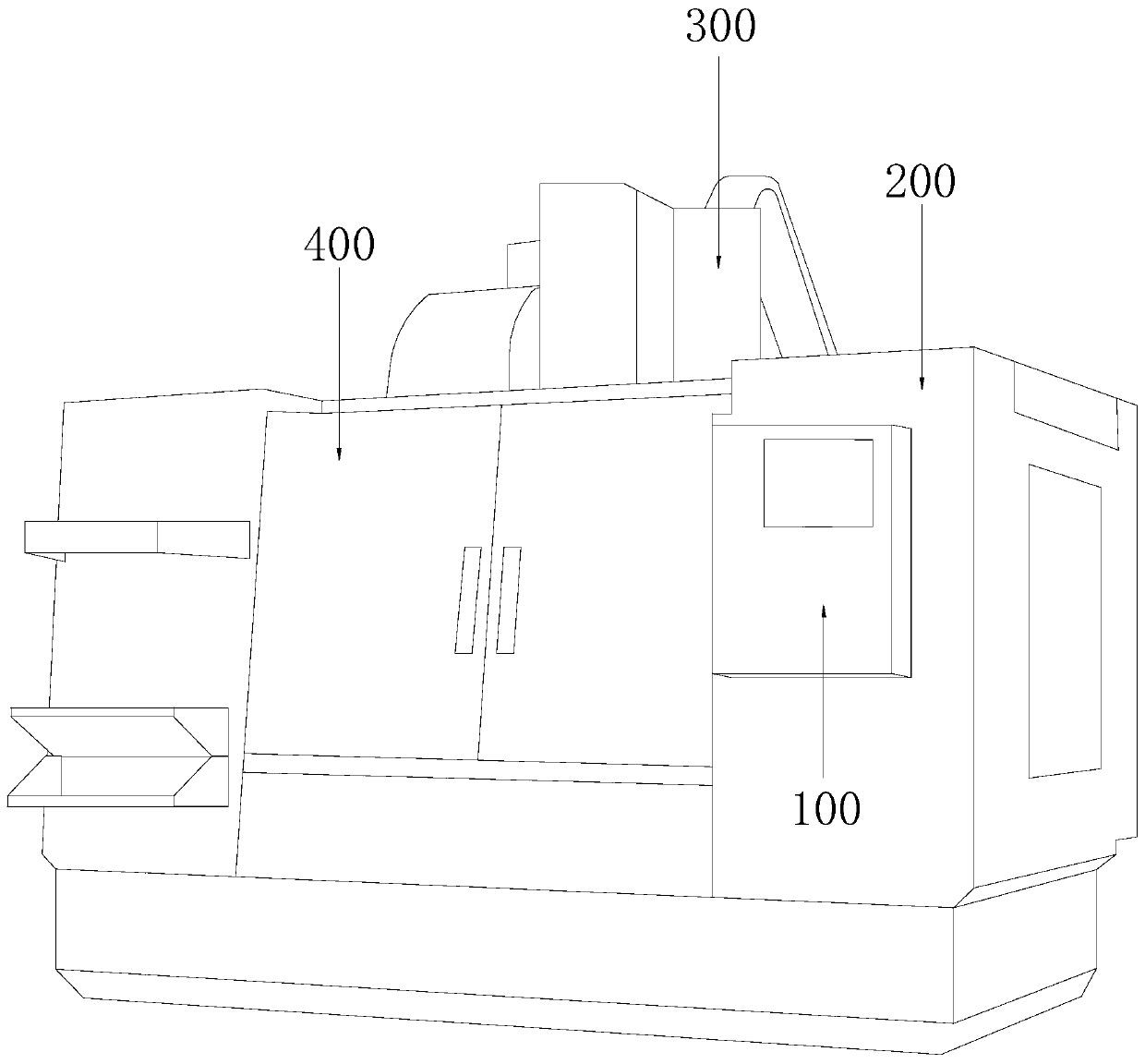

[0036] see Figure 1-7 , the present invention provides a technical solution for a fast clamping metal cutting machine tool: its structure includes a controller 100, a metal cutting machine tool body 200, a metal cutting device 300, a protective door 400, and a quick chuck 500 for cutting parts. The machine tool body 200 is equipped with a controller 100, the controller 100 is electrically connected to the metal cutting device 300, and the cutting part quick chuck 500 is provided directly below the metal cutting device 300, and the cutting part quick chuck 500 is built in Metal cutting machine tool body 200, the metal cutting machine tool body 200 is hinged with a protective door 400;

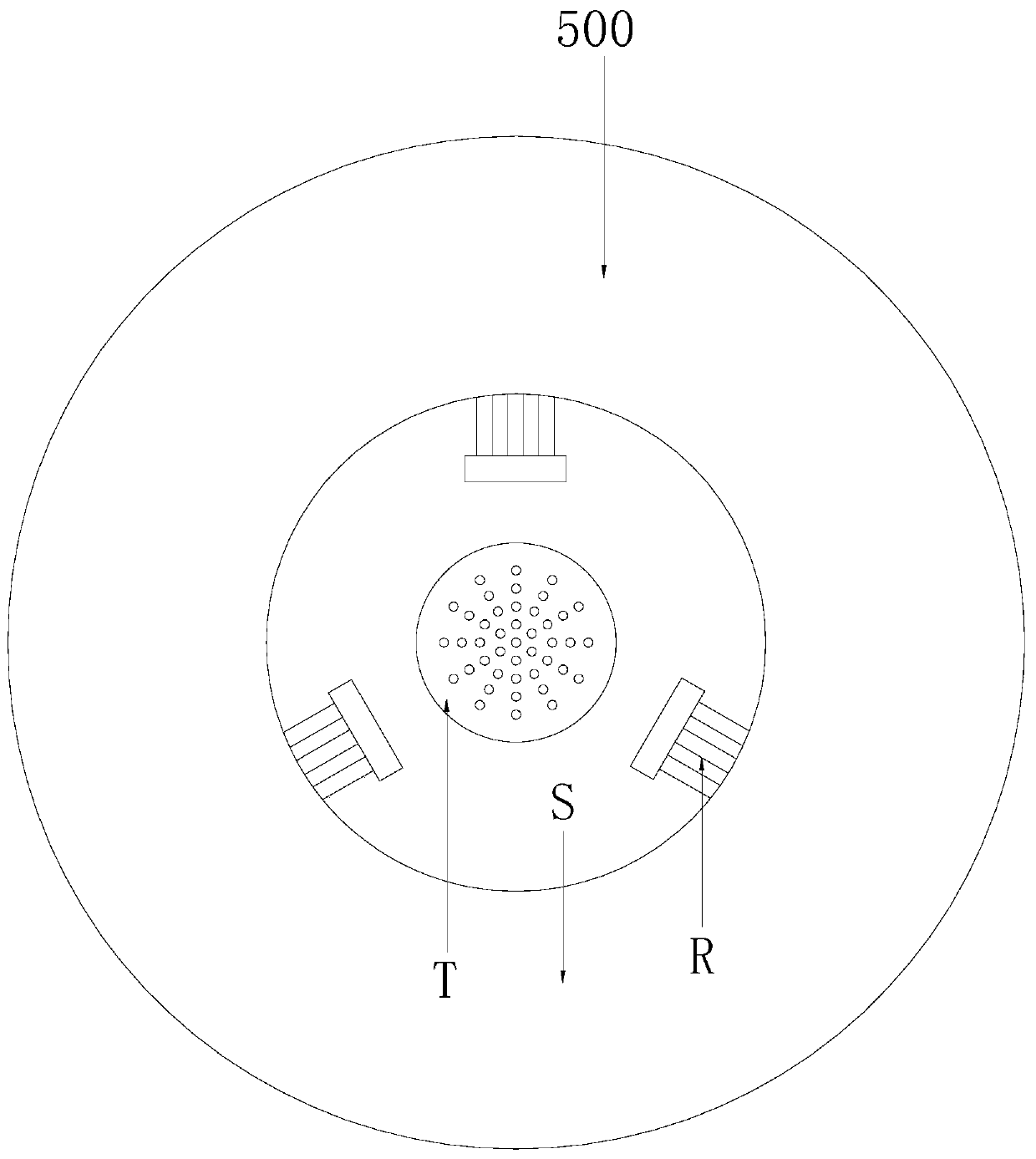

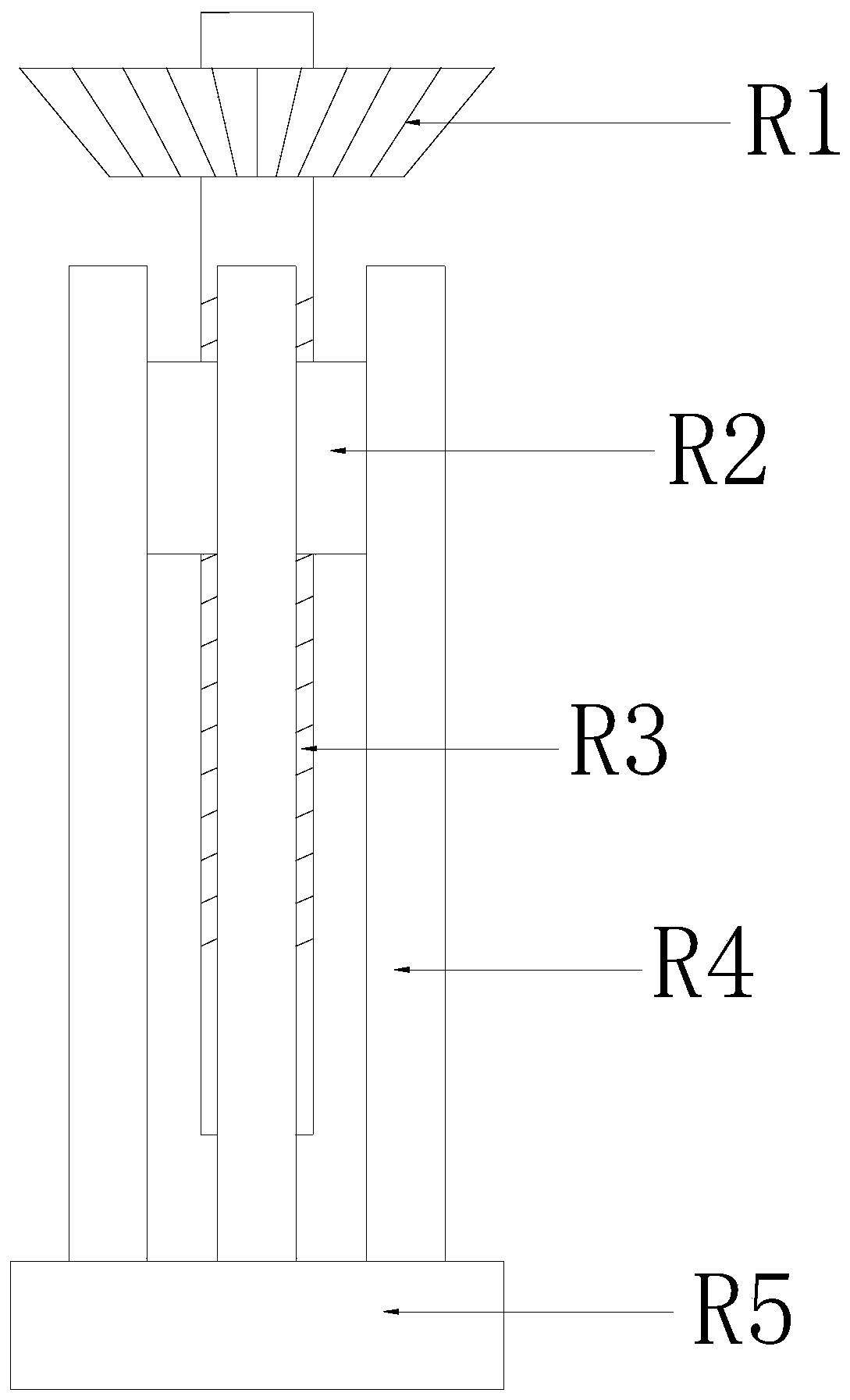

[0037] The cutting quick chuck 500 includes a main clamping mechanism R, a chuck S, and an auxiliary clamping mechanism T. The main clamping mechanism R is arranged on three equal parts of the chuck S, and the chuck S is also provided with an auxiliary clamping mechanism T, the main clamping m...

Embodiment 2

[0045] see Figure 1-9 , the present invention provides a technical solution for a fast clamping metal cutting machine tool: its structure includes a controller 100, a metal cutting machine tool body 200, a metal cutting device 300, a protective door 400, and a quick chuck 500 for cutting parts. The machine tool body 200 is equipped with a controller 100, the controller 100 is electrically connected to the metal cutting device 300, and the cutting part quick chuck 500 is provided directly below the metal cutting device 300, and the cutting part quick chuck 500 is built in Metal cutting machine tool body 200, the metal cutting machine tool body 200 is hinged with a protective door 400;

[0046] The cutting quick chuck 500 includes a main clamping mechanism R, a chuck S, and an auxiliary clamping mechanism T. The main clamping mechanism R is arranged on three equal parts of the chuck S, and the chuck S is also provided with an auxiliary clamping mechanism T, the main clamping m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com