Anti-counterfeiting printing equipment

A technology of anti-counterfeiting printing and equipment, which is applied in the direction of spraying devices, coatings, liquid spraying devices, etc., can solve the problems of low efficiency and failure of anti-counterfeiting operations such as scratching and winning prizes, and achieve high-efficiency printing and covering, increased work efficiency, and simple equipment structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

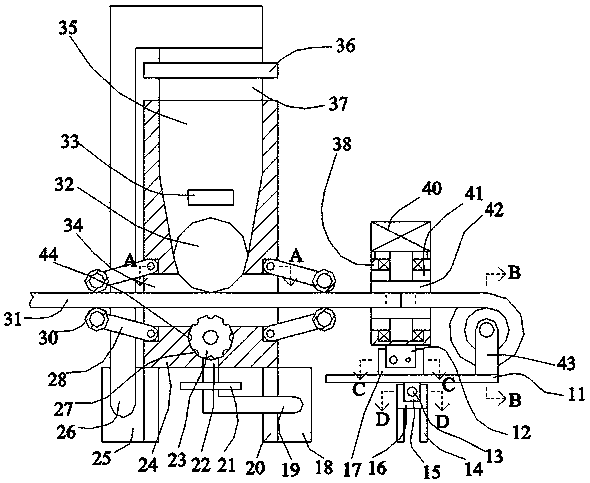

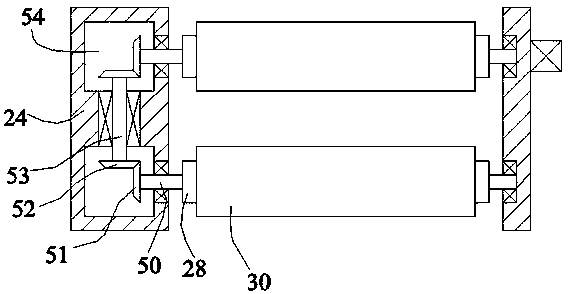

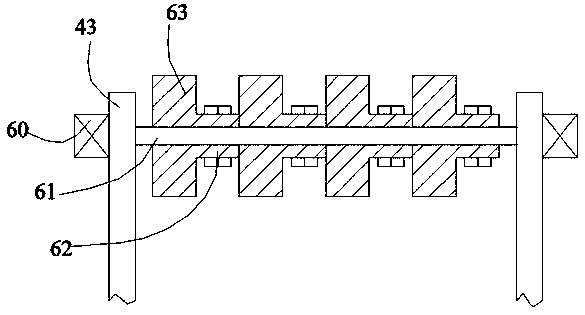

[0024] Such as Figure 1-Figure 5 As shown, the present invention is described in detail. For the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1The up, down, left, right, front and back directions of the projection relationship itself are consistent. An anti-counterfeiting printing device of the present invention includes a side box 24, and the side box 24 is provided with a penetrating 34, and the lower end surface of the side box 24 is fixed with a symmetrical The supporting foot 20, the two sides of the supporting foot 20 are respectively fixed with a liquid storage tank 25 and a storage tank 18, and the storage inner chamber 35 located in the side box 24 is arranged above the said 34, and the storage inner chamber 35 communicates with the 34, so that the upper side of the storage cavity 35 is communicated with a bottom connecting pipe 37, and the bottom connecting pipe 37 is connected with a top side valve body 36, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com