Centrifugal rotating spiral concentrator

A spiral concentrator and centrifugal separation technology, applied in the field of beneficiation, can solve the problems such as the large influence of material separation and layering effect parameters, the difficulty in ensuring the stability of the separation process, the low separation efficiency and the low processing, and the like. Sorting efficiency and effects of low processing, high integration and high sorting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

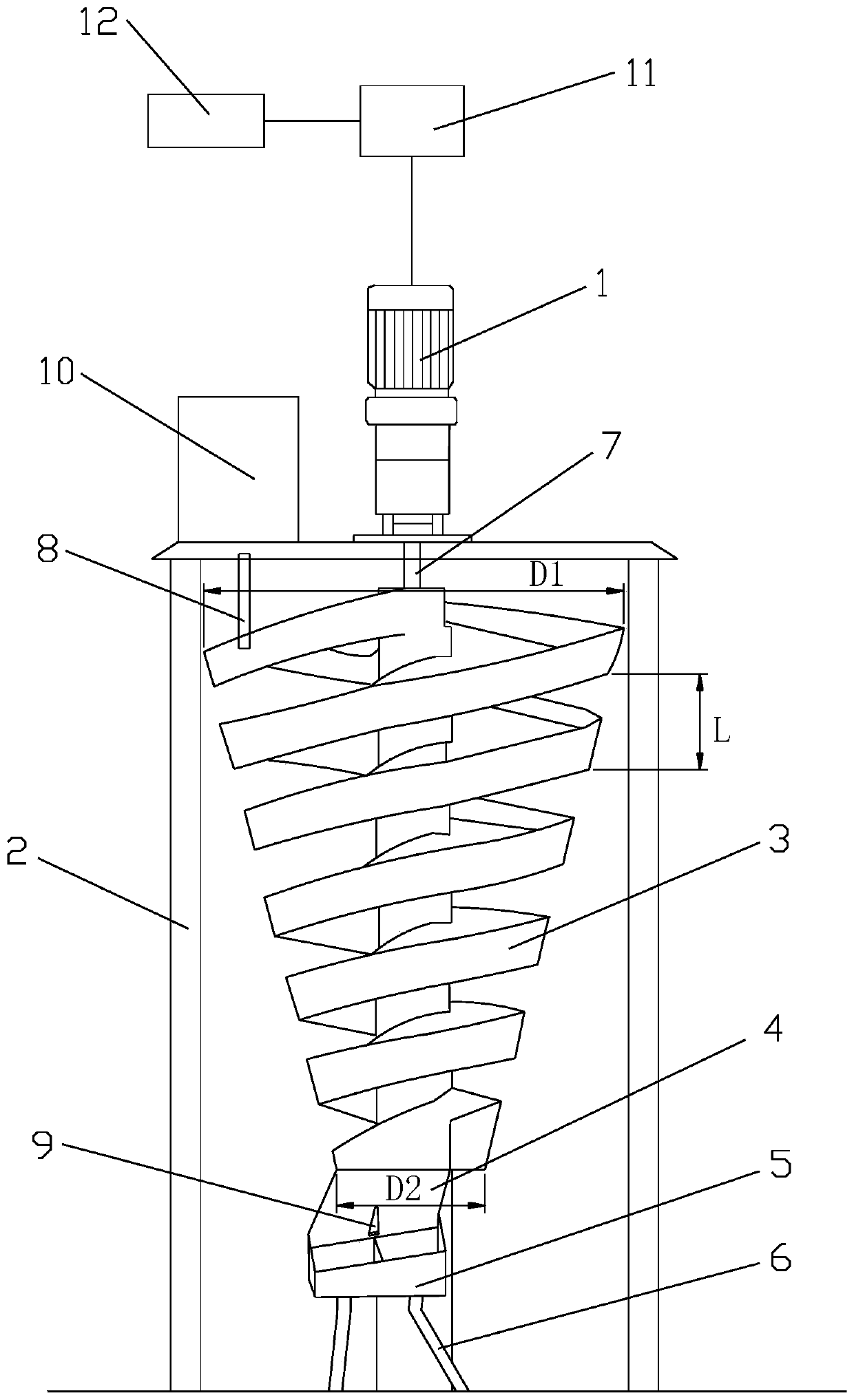

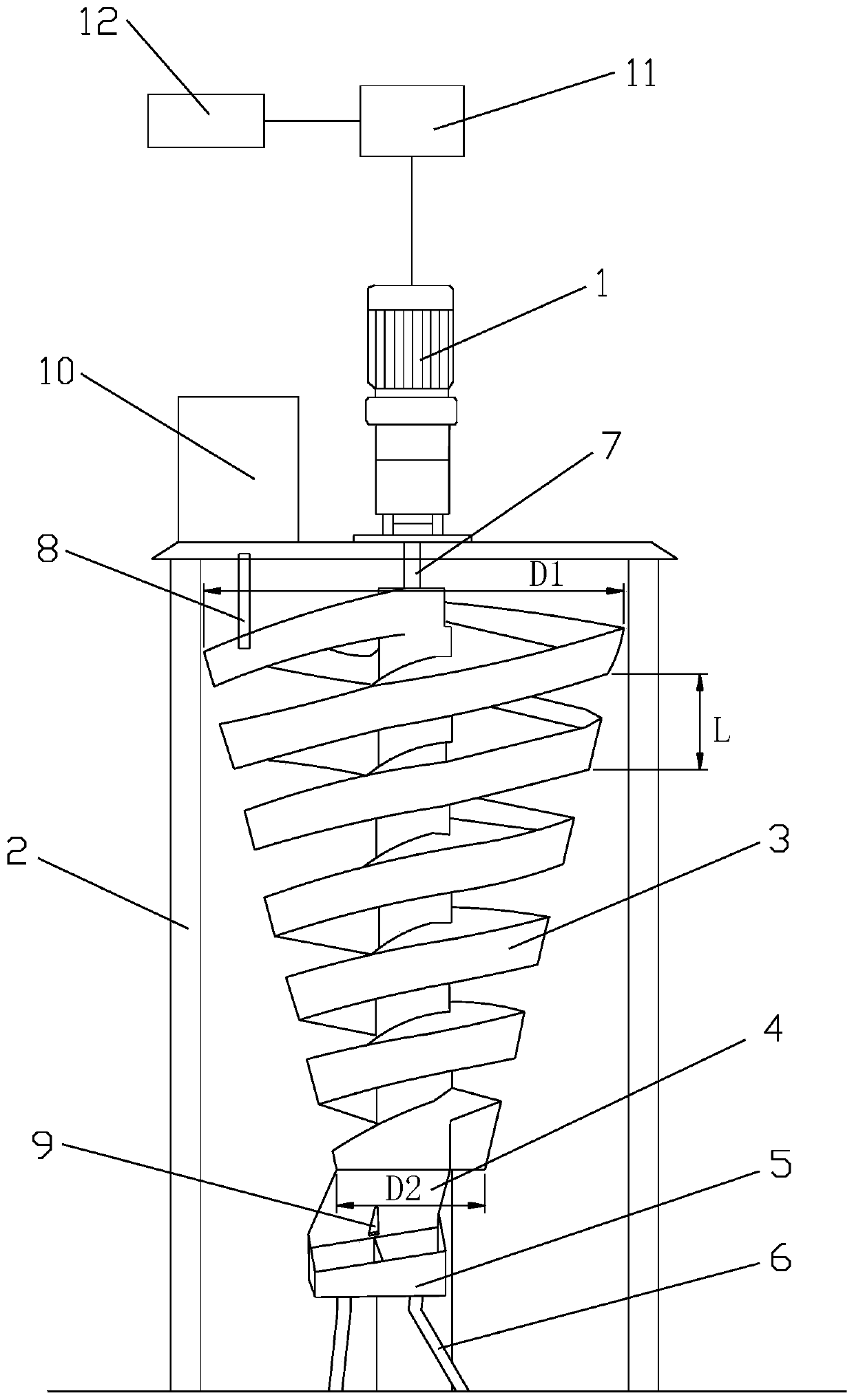

[0029] like figure 1 A centrifugal rotating spiral mineral concentrator shown includes a frame 2, a rotating main shaft 7, a feeding box 10, a spiral centrifugal separation tank 3, a reduction motor 1, a frequency converter 11, a controller 12 and a multi-product receiving mechanism, The rotating main shaft 7 is vertically installed in the frame 2 along the central axis of the frame 2, the upper end of the rotating main shaft 7 is connected with the top center of the frame 2 in rotation, and the lower end of the rotating main shaft 7 is connected with the bottom of the frame 2. The center of the bottom is rotationally connected, the spiral centrifugal separation tank 3 is fixedly installed on the outer wall of the rotating main shaft 7, the feed box 10 is arranged on the top side of the frame 2, and the bottom of the feed box 10 is provided with a Give the feed port 8 of the spiral centrifugal separation tank 3 feeding, the lower end of the feed port 8 is located at the feed i...

Embodiment 2

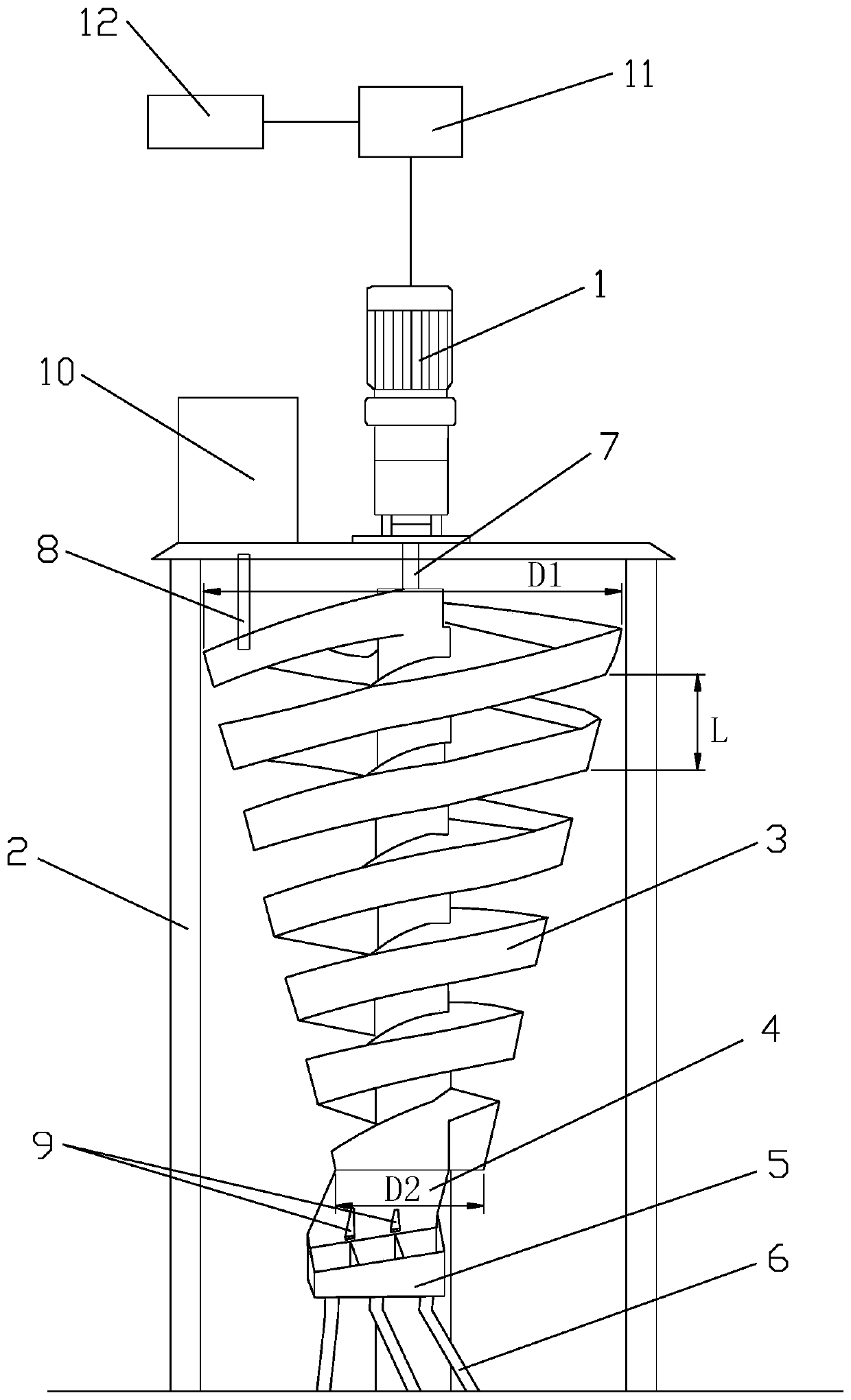

[0042] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the number of the distribution grids 9 is two, the number of notches in the receiving trough 5 and the number of discharge pipes 6 are three. Two distribution grids 9 can divide the distribution chute 4 into three distribution troughs; correspondingly, the number of notches in the receiving chute 5 and the number of discharge pipes 6 are three, each receiving material The notches in the tank 5 correspond to a distribution tank and a discharge pipe 6 respectively. Three distribution grids 9 are used to separate materials of different densities, and three products of different densities can be produced, namely light products, heavy products and mid product. The kind of sorting product is determined by the number of material distribution grids 9 . The lower ends of the three discharge pipes 6 can respectively extend into three ring-shaped hoppers to collect materials. The three ring-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com