Duct type cooling fan

A ducted and fan technology, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of poor cooling effect of refrigeration fans, and achieve the effect of accelerating cooling and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

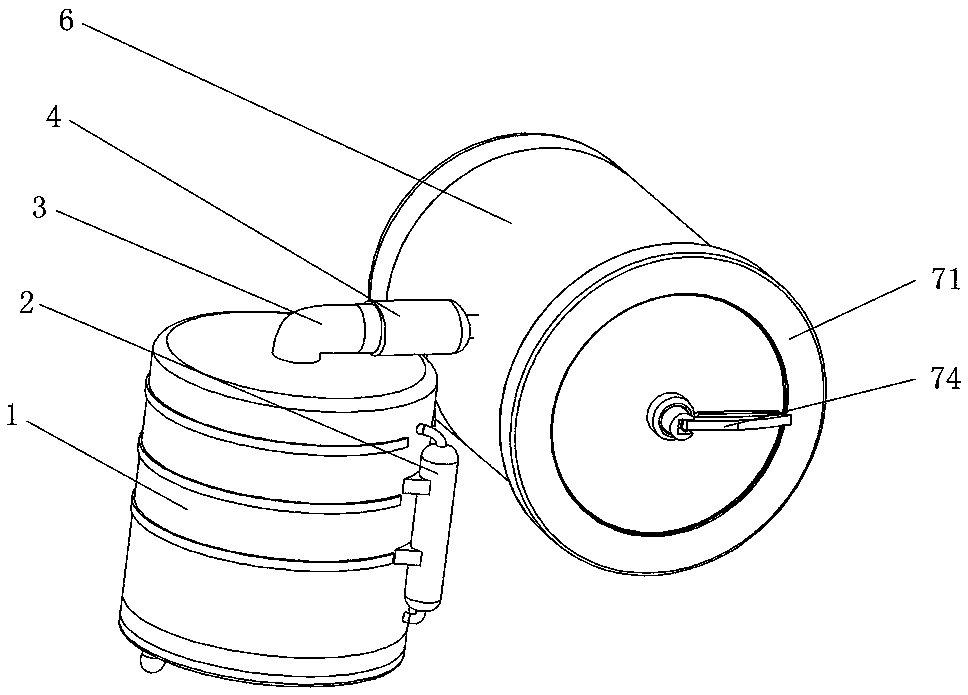

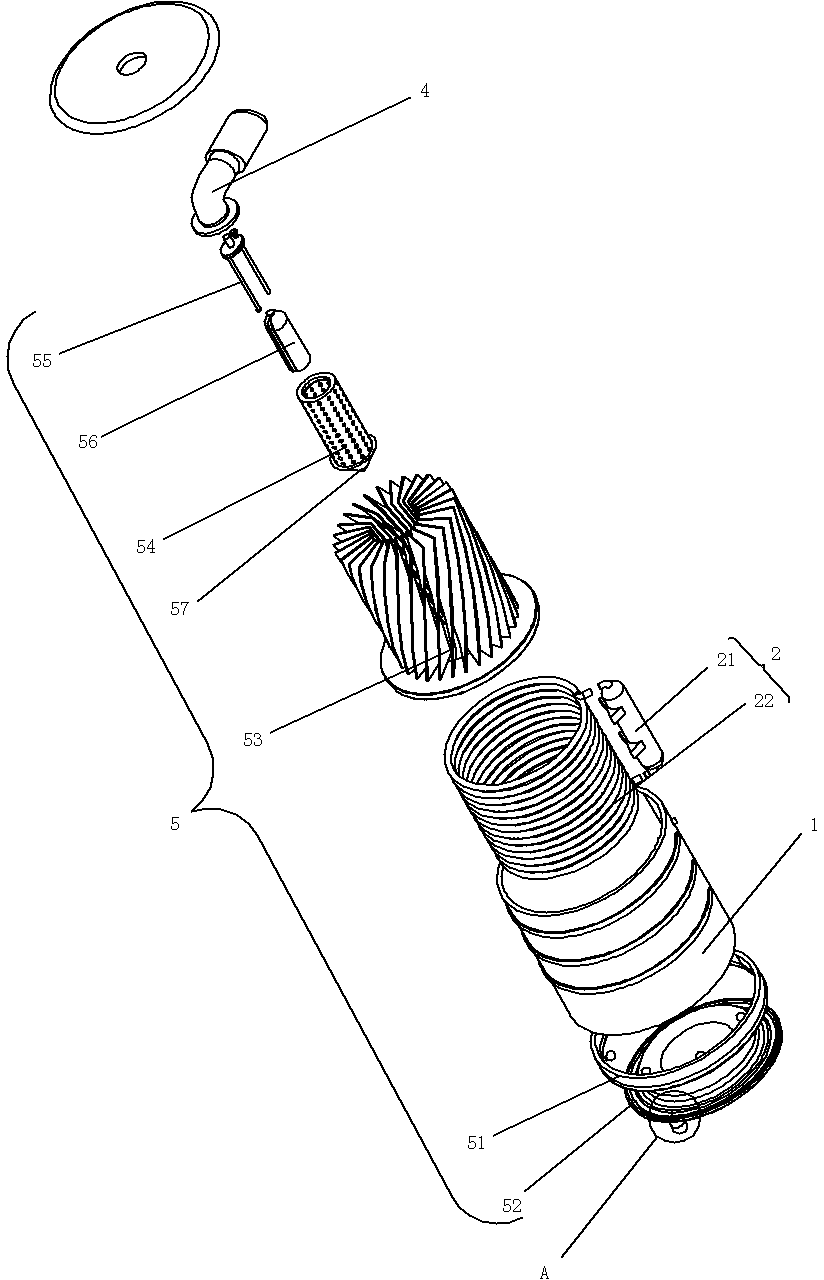

[0034] Such as figure 1 , 3, 4, 5, and 7, the embodiment of the present invention provides a ducted refrigeration fan, including a cooling cylinder 1, the upper end of the cooling cylinder 1 is connected with an air guide pipe 3, and the other end of the air guide pipe 3 is connected with a suction fan 4, The surface of the suction fan 4 is fixedly connected with the cooling cylinder 1, and the other end of the suction fan 4 is connected with a pipeline 6, which is vertically arranged with the cooling cylinder 1, and the surface of the pipeline 6 is fixedly connected with the cooling cylinder 1, and the surface of the cooling cylinder 1 is provided with The cooling mechanism 2, the cooling mechanism 2 includes a compressor 21, the surface of the compressor 21 is fixedly connected to the surface of the cooling cylinder 1, the port of the cooling cylinder 1 is connected with an exchange tube 22, and the surface of the exchange tube 22 runs through the side wall of the cooling cy...

Embodiment 2

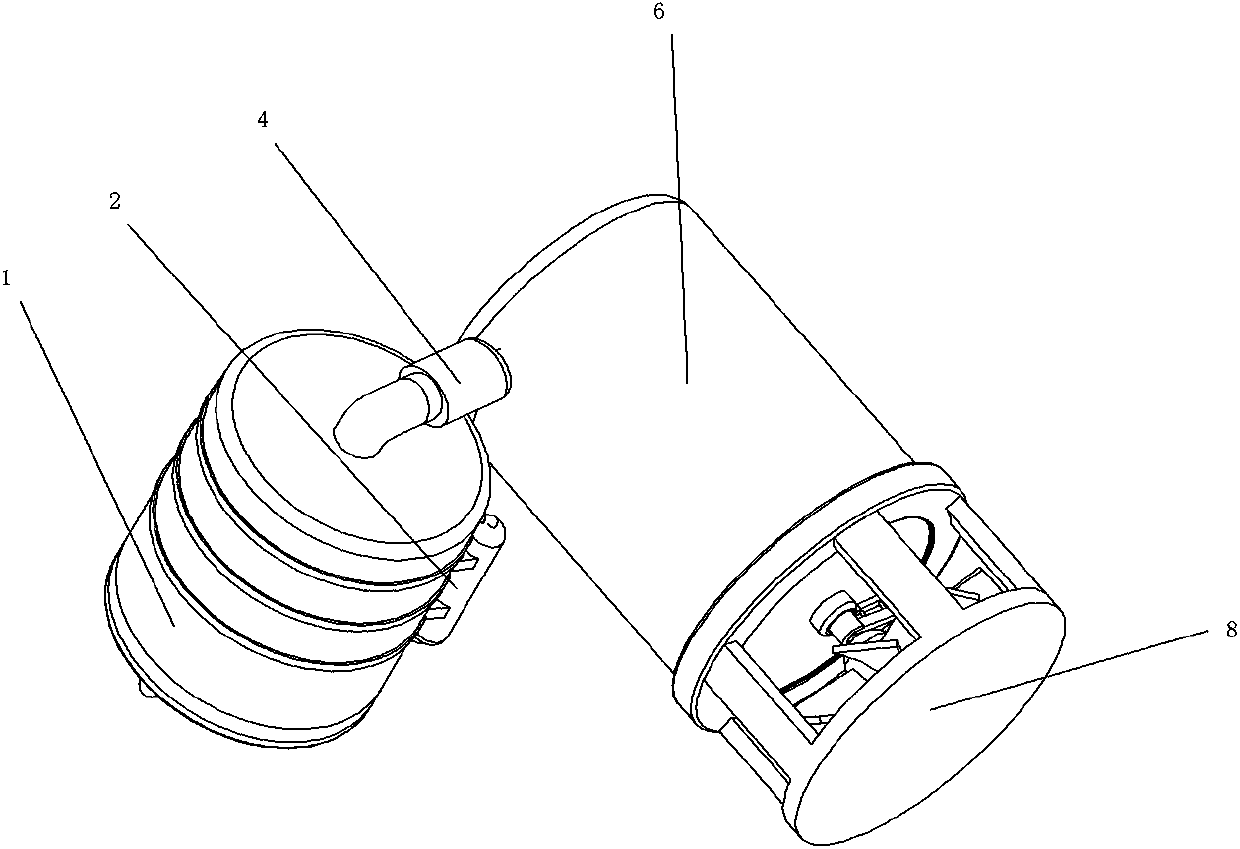

[0038] Such as figure 2 , 6 As shown, the embodiment of the present invention provides a ducted refrigeration fan. On the surface of the upper limit ring 71 of the specific embodiment 1, an air guiding device 8 is fixedly connected. The air guiding device 8 includes a connecting piece 801, one end of the connecting piece 801 and The limit ring 71 is fixedly connected, the other end of the connecting piece 801 is fixedly connected with a baffle 802, the size of the baffle 802 is suitable for the limit ring 71, and the end of the baffle 802 close to the limit ring 71 is rotatably connected with a wind deflector 803 , using the air guiding device 8 to prevent the cold air from being directly blown out by the pipe 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com