Hospital waste burn-out furnace and burn-out treatment method

A technology for hospital waste and treatment methods, applied in the directions of combustion methods, incinerators, combustion types, etc., can solve the problems of air pollution, harm to descendants, polluted land and water sources, etc., and achieve the effect of improving work efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

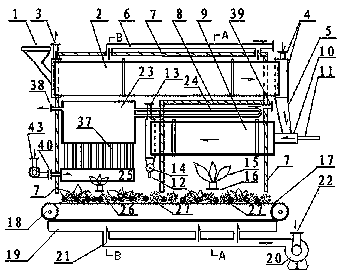

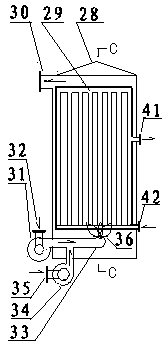

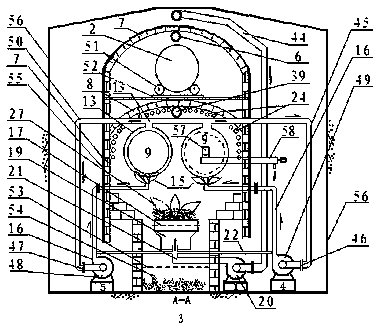

[0057] A hospital garbage incineration furnace and its incineration treatment method, comprising: a garbage feeding hopper 1, a rotary dryer 2, a kiln head cover and an exhaust pipe 3, a kiln tail cover and an air intake pipe 4, and a dry garbage distributor 5 , burnout furnace exhaust pipe 6, burnout furnace body 7, carbonization furnace body 8, rotary carbonization furnace 9, carbonization furnace hydraulic feeder 10, hydraulic push rod 11, glue removal oil pipe 12, rotary carbonization furnace tail cover and row Air port 13, toner discharge auger 14, mixed gas combustion flame 15, mixed gas pipe 16, chain grate of burnout furnace 17, chain row driving wheel 18, bellows 19, No. 1 blower 20, No. 1 blower outlet pipe 21 , No. 4 and No. 5 blower air distribution pipe 22, waste heat boiler 23, carbonization furnace waste heat coil 24, boiler lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com