Vertical freezing construction method for underneath comprehensive pipeline such as high voltage cable of city subway

A technology of high-voltage cables and construction methods, which is applied to earthwork drilling, mining equipment, tunnels, etc., and can solve problems such as long periods, pipelines affected by low temperature, and foundation pit precipitation affecting frozen walls, etc., achieving high economic benefits and safe construction reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

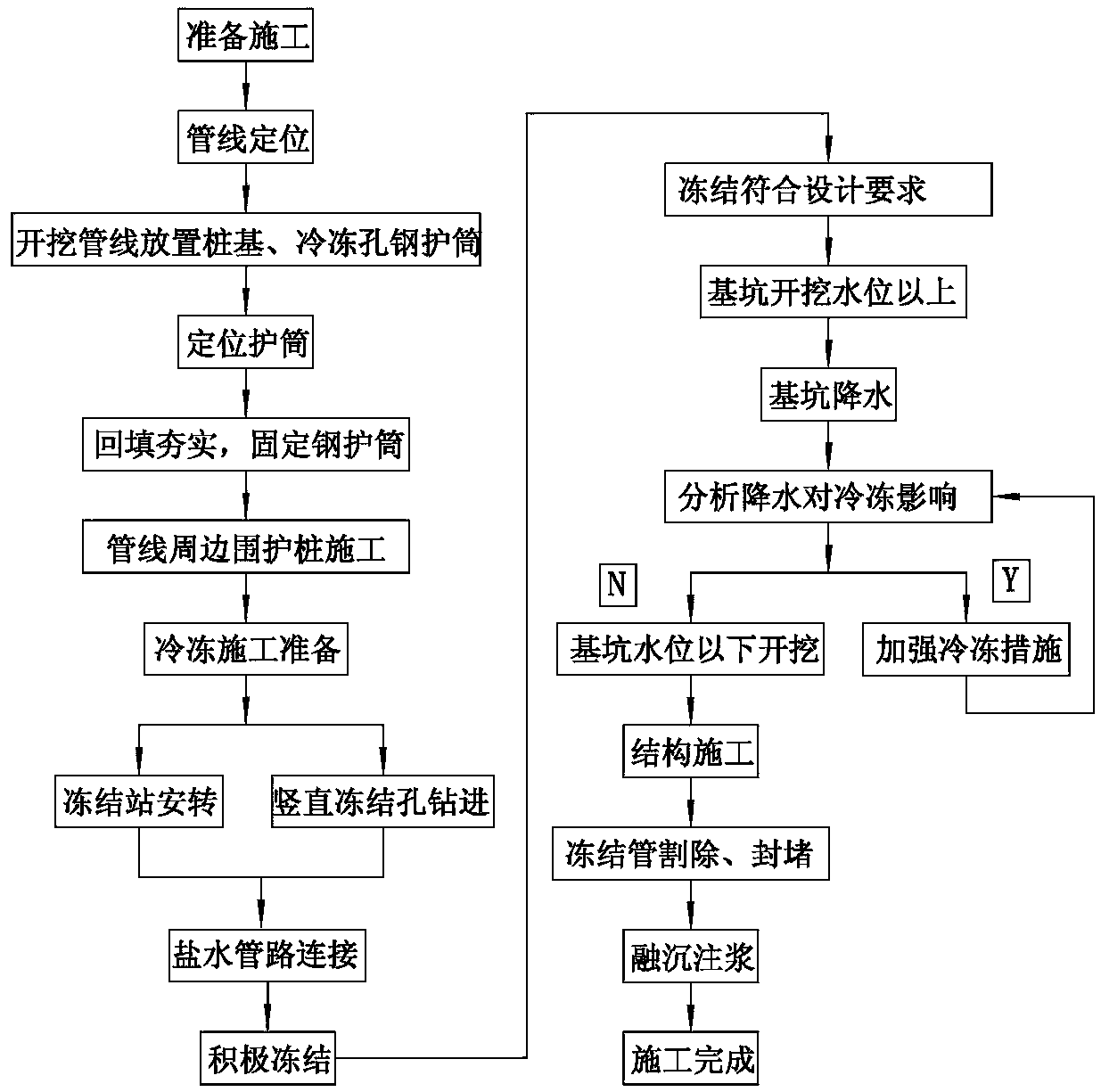

[0044] Jinan Metro Line R1 Dayangzhuang Station No. 1 Wind Pavilion and Exit A are located at the northwest corner of the intersection of Jingshi West Road and Qilu Avenue. It is a super large special-shaped foundation pit with an excavation area of about 3000m 2 , The maximum excavation depth is 15m, and the average excavation is 12m. The water level in the pit drops to 8m. There are many surrounding pipelines, and 220KV and 10KV power pipelines mainly affect the construction of the auxiliary structure of Dayangzhuang Station. The enclosure structure is affected by the 220KV power draw pipe. The pipeline under the enclosure structure is closed and there are gaps. Due to the complex geology and the large amount of groundwater, accidents are prone to occur during the excavation of the foundation pit. The use of an urban subway underpasses high-voltage cables. The vertical freezing construction method of the pipeline is carried out, such as figure 1 As shown, it specifically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com