Assembly type short-limb underground continuous wall

An underground continuous wall and prefabricated technology, which is applied in the direction of sheet pile walls, excavation, construction, etc., can solve the problems of complex construction steps and prolong the construction period of the building, and achieve the effect of shortening the construction period and reducing the construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

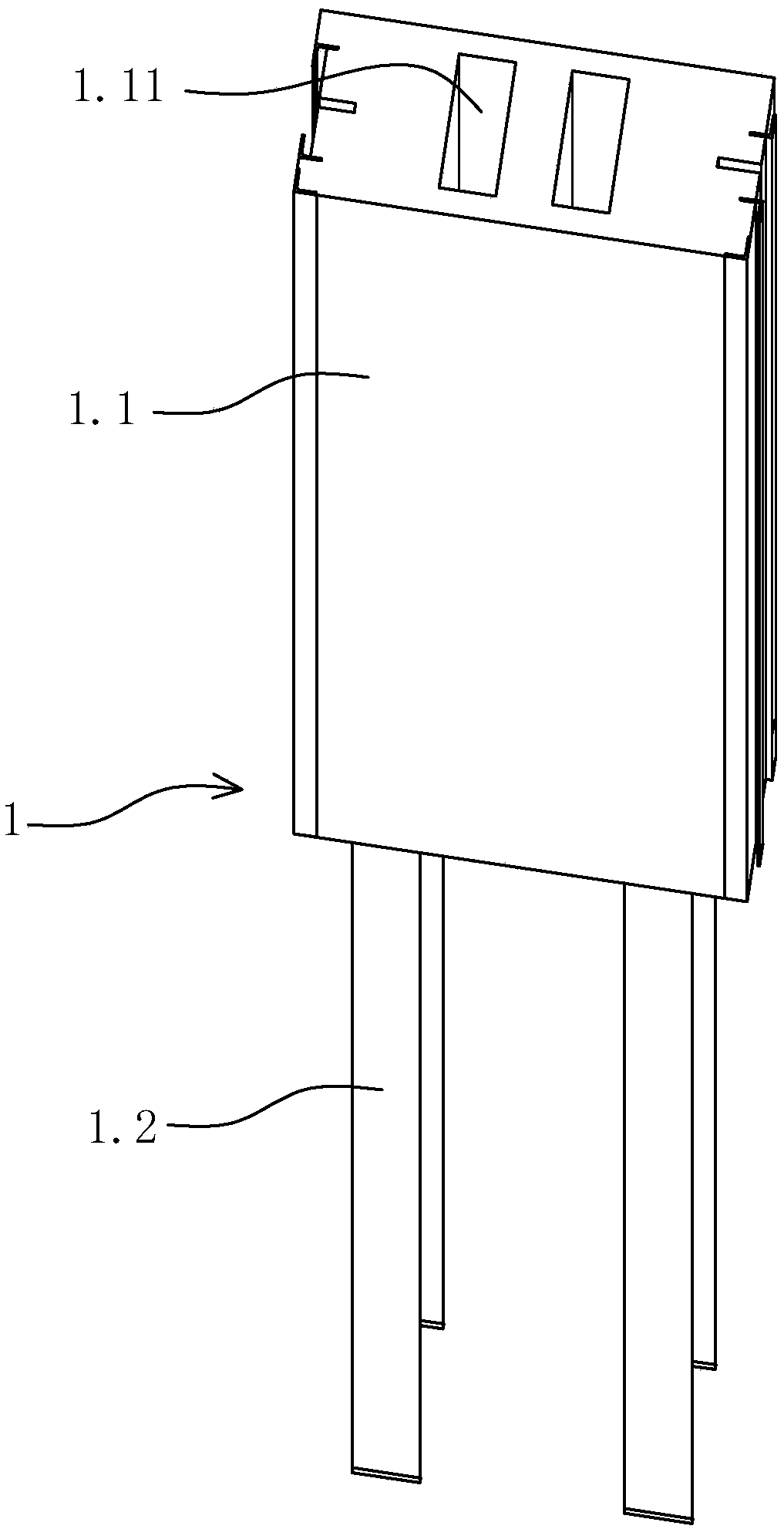

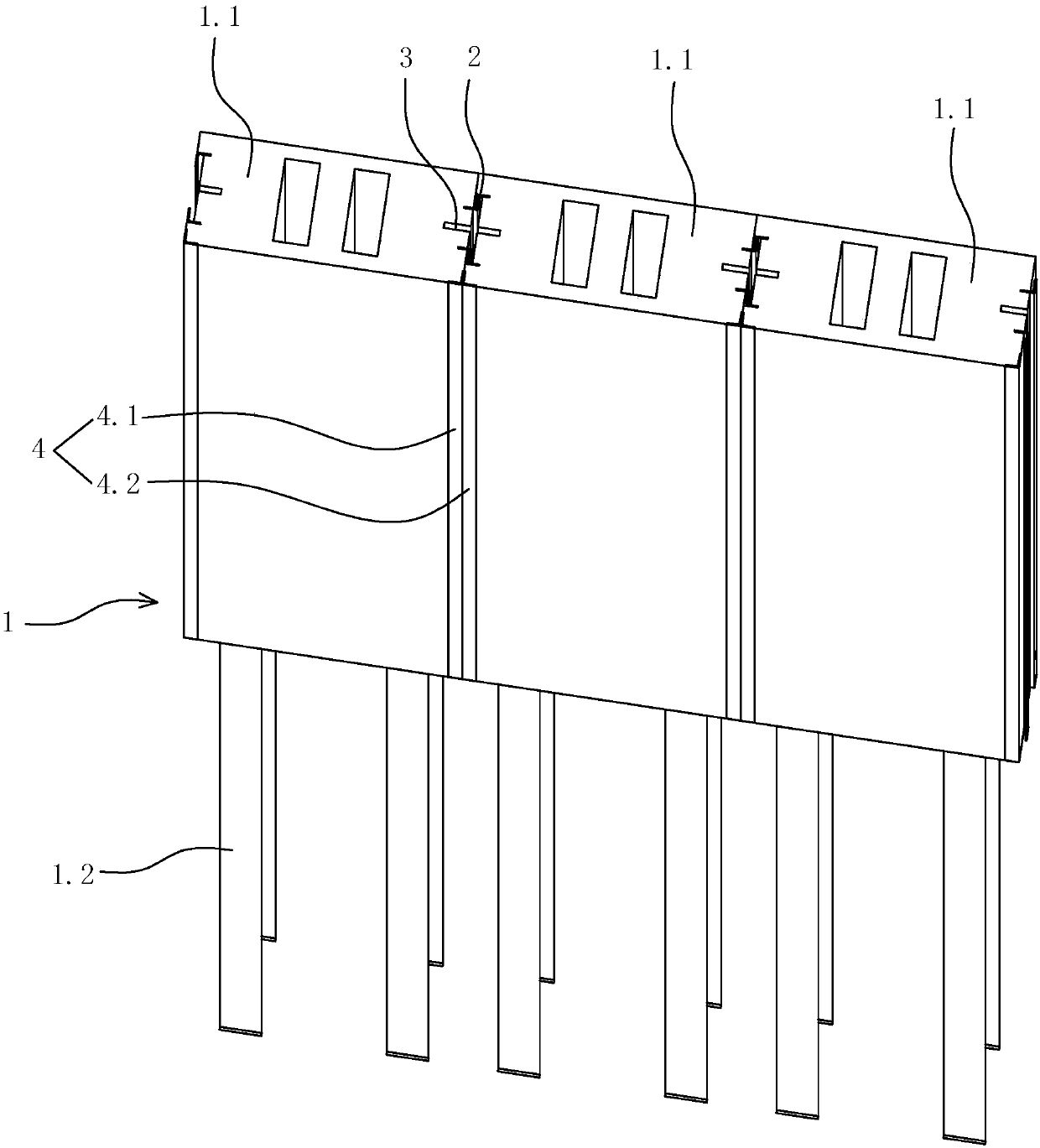

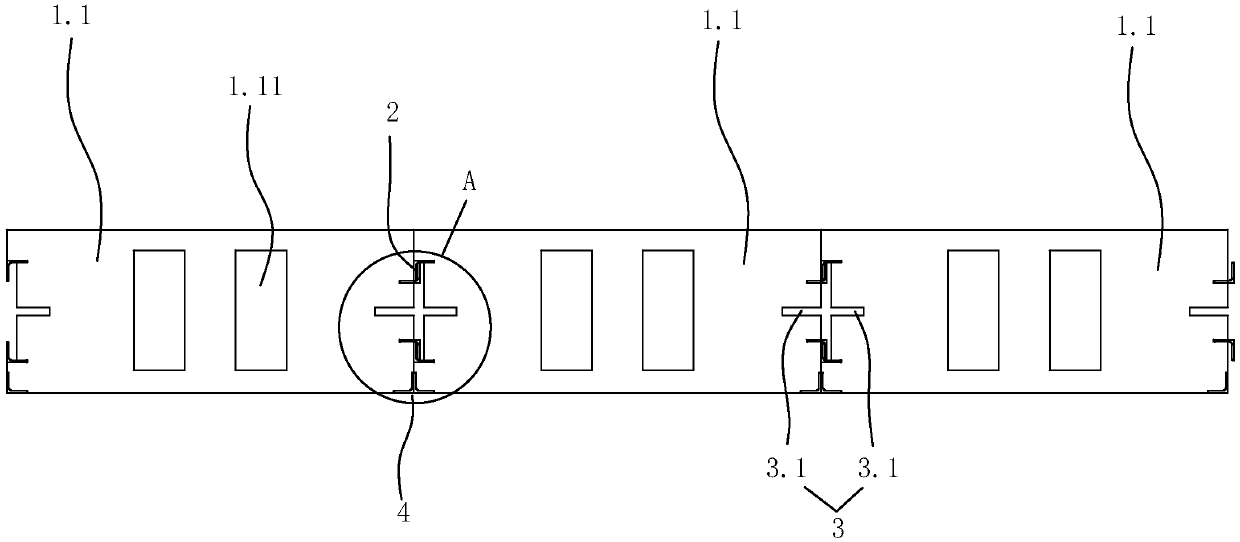

[0038] Specific embodiment one: as figure 1 , figure 2 As shown, a prefabricated short-leg underground diaphragm wall includes an underground cement-soil diaphragm wall and a prefabricated diaphragm wall with outriggers. The underground cement-soil continuous wall is arranged around the foundation pit. The underground cement-soil diaphragm wall is used to block groundwater to form the enclosure of the foundation pit.

[0039] The prefabricated continuous wall with outriggers includes prefabricated single walls 1 sequentially arranged in the underground cement-soil continuous wall along the length direction of the underground cement-soil continuous wall. The prefabricated monolithic walls are set vertically.

[0040] The prefabricated single wall includes a prefabricated reinforced concrete component 1.1 arranged in the underground cement-soil continuous wall and a section steel component 1.2 located below the prefabricated reinforced concrete component. In this embodimen...

specific Embodiment 2

[0051] Specific embodiment two: as Figure 5 , Figure 6 As shown, the rest of the structure of this embodiment refers to the specific embodiment one, the difference is:

[0052] A prefabricated short limb underground continuous wall also includes an expansion support device 5 arranged at the lower part of the prefabricated reinforced concrete member 1.1. The expansion support device includes a horizontal chute 5.1 arranged at the lower part of the side of the prefabricated reinforced concrete member, a sliding support plate 5.2 slidably arranged in the horizontal chute, and a housing arranged in the lower part of the prefabricated reinforced concrete member and communicated with the horizontal chute. Groove 5.0, horizontal cylinder 5.3 embedded in the lower part of the prefabricated reinforced concrete member, piston 5.4 slidingly arranged in the horizontal cylinder and piston rod 5.5 connected with the piston.

[0053] There are two horizontal chutes in the same expansion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com