Hydraulic power and fracturing combined resonant gas extraction method for coal bed and hole packer

A technology for hydraulic fracturing and gas drainage, which is applied in the field of coal seam hydraulic fracturing combined with resonance gas drainage method and hole sealing device, can solve problems such as insufficient gas drainage efficiency, and achieves improved regional fracture-making effect and huge economic benefits. and social benefits, and the effect of improving the degree of fissure development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

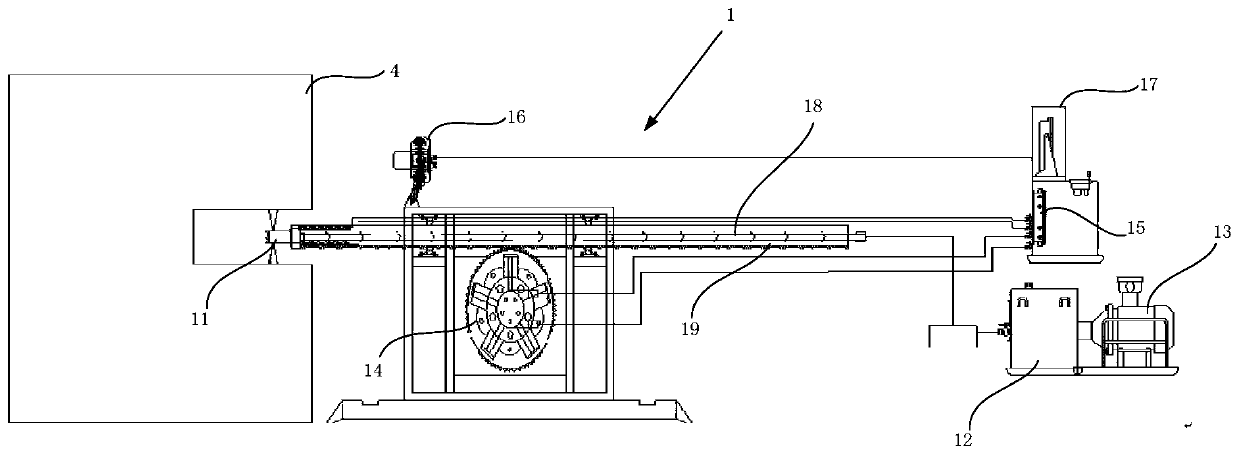

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

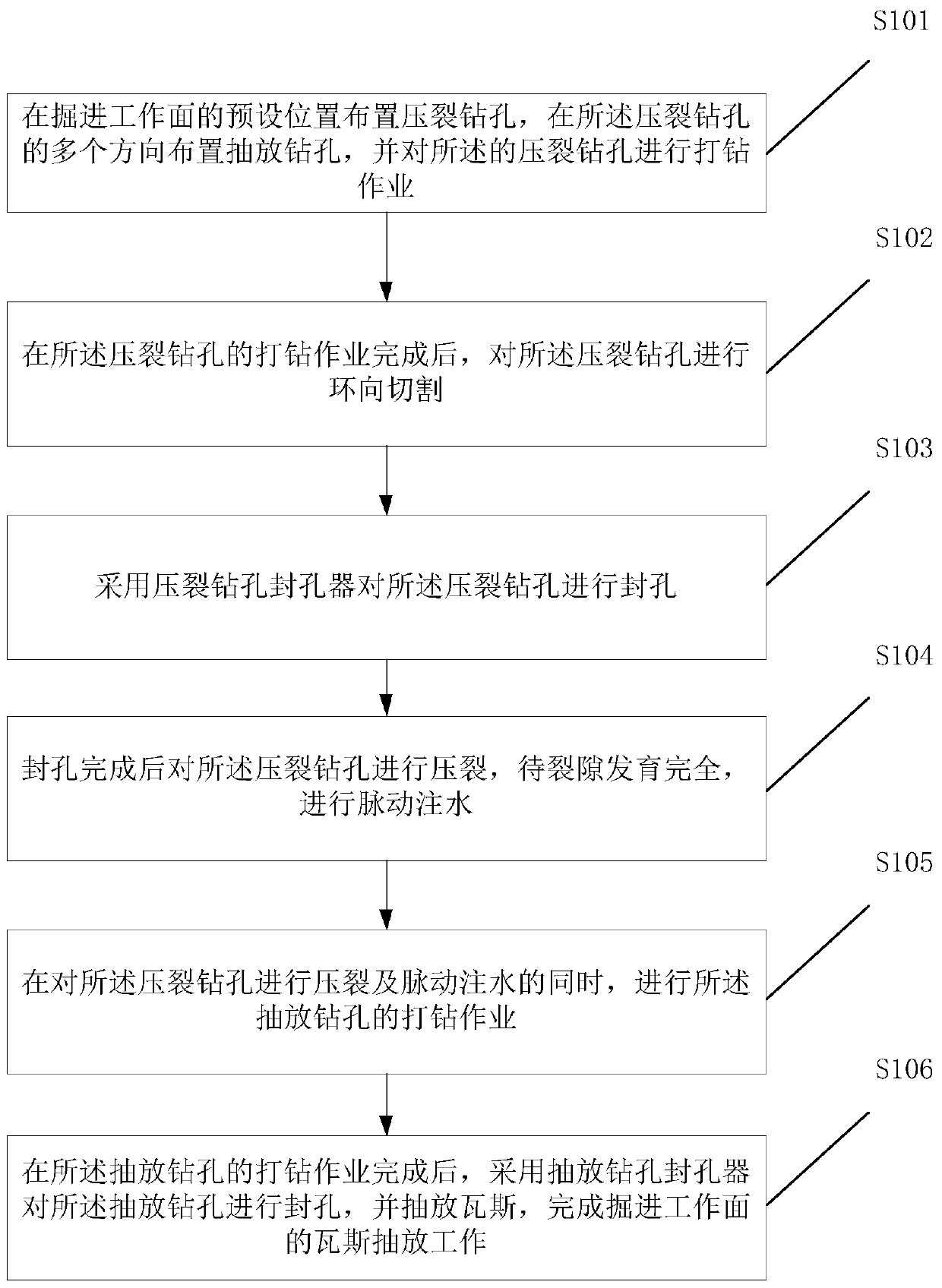

[0043] Such as figure 1 Shown is a working flow chart of a coal seam hydraulic fracturing combined resonance drainage gas method of the present invention, including:

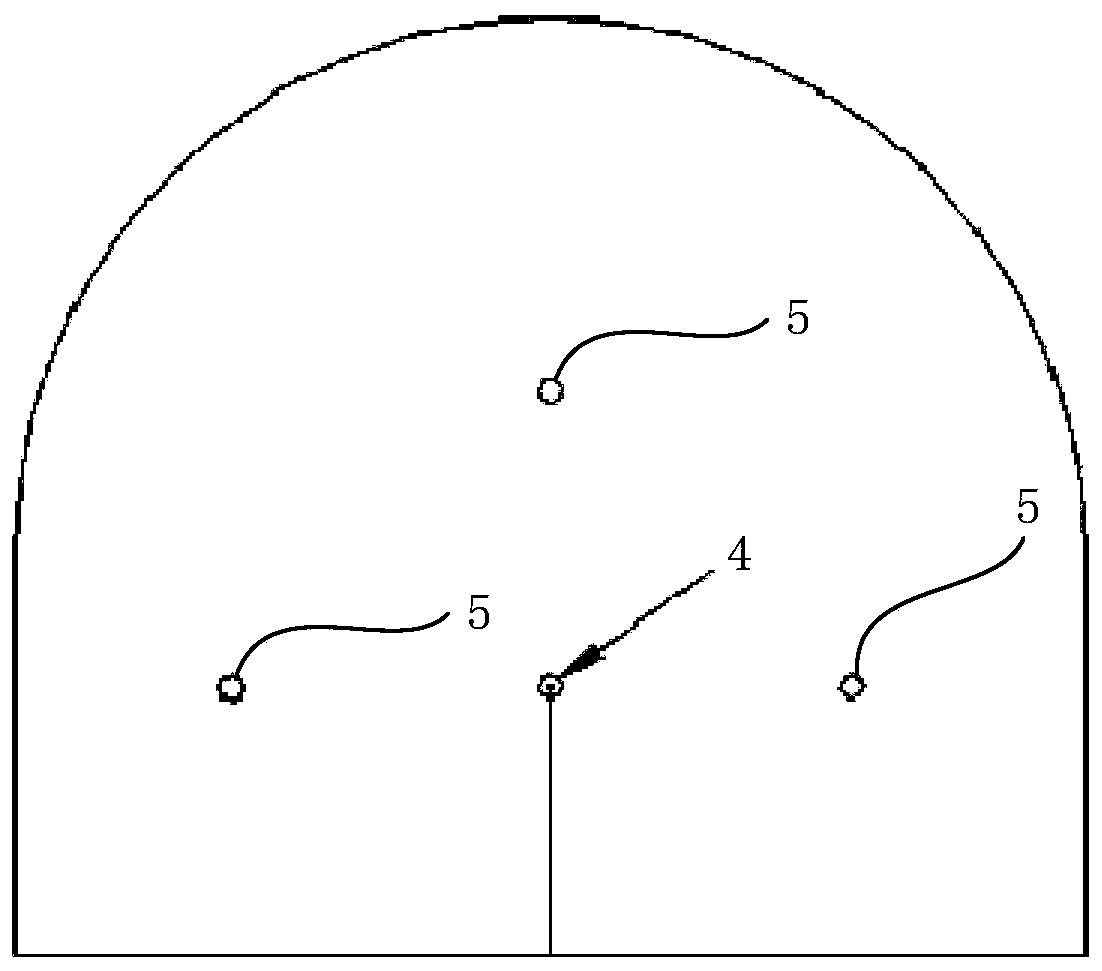

[0044] Step S101, arranging fracturing boreholes at preset positions on the excavation face, arranging drainage boreholes in multiple directions of the fracturing boreholes, and performing drilling operations on the fracturing boreholes;

[0045] Step S102, after the drilling operation of the fracturing borehole is completed, perform circumferential cutting on the fracturing borehole;

[0046] Step S103, using a fracturing drilling sealer to seal the fracturing drilling;

[0047] Step S104, after the hole sealing is completed, perform fracturing on the fracturing borehole, and perform pulsating water injection when the fractures are fully developed;

[0048] Step S10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com