Open hole packer staged fracturing string with accurate crack distribution and use method

A staged fracturing and packer technology, which is applied in the directions of sealing/isolation, earthwork drilling, wellbore/well components, etc. The fracture position is affected by the ground stress and natural fractures, and the stimulation effect is poor, so as to reduce the contact area, improve the fracture creation effect, and balance the stimulation effect of the reservoir

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

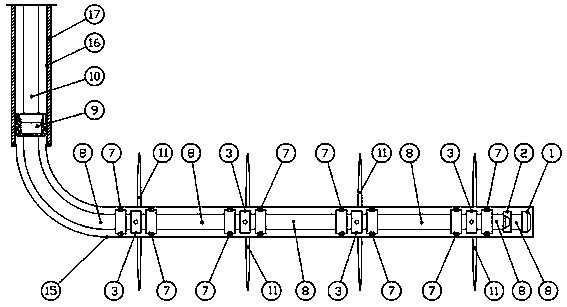

[0024] Such as figure 1 As shown, a staged fracturing string of an open hole packer with precise seams includes a main oil pipe 8 connected with a plurality of sliding sleeves 3 distributed at intervals, and a plurality of seals are also connected with the main oil pipe 8 . The packer set, the packer set and the sliding sleeve 3 correspond one by one, the packer set includes two packers 7 connected to the main oil pipe 8, and the two packers 7 are respectively connected to the sliding sleeve 3 On both sides, clamp the corresponding sliding sleeve 3 in the middle.

[0025] The main oil pipe 8 is divided into multiple stages, each stage is 80-150m long, and a sliding sleeve 3 is connected to the center of each stage.

[0026] The main tubing 8 is divided into multiple stages, each stage has a sliding sleeve 3 and a packer set, the sliding sleeve 3 is located in the middle of the corresponding stage, and the two packers 7 of the packer set are connected to the sliding sleeve 3 ...

Embodiment 2

[0028] Such as figure 1 As shown, on the basis of Example 1, the oil manifold 8 is also connected with a setting joint 2, the setting joint 2 is located behind the rearmost packer 7, and the oil manifold behind the setting joint 2 Also be connected with floating shoes 1 on the 8.

[0029] The main oil pipe 8 is formed by connecting multiple oil pipes, and the two packers 7 in the packer group of the sliding sleeve 3 are separated from the middle sliding sleeve 3 by the length of one oil pipe. Avoiding that the two packers 7 and the sliding sleeve 3 are connected together is too rigid, resulting in difficulty in going downhole.

[0030] The main oil pipe 8 is formed by connecting several oil pipes in sequence, and there is an oil pipe between each packer 7 and the corresponding sliding sleeve 3, that is, a length of 10 meters.

[0031] The front end of the main oil pipe 8 is connected with a return oil pipe 10 through a hanger 9, and the other end of the oil return pipe 10 is...

Embodiment 3

[0035] Such as figure 1 As shown, on the basis of Example 2, a method for using a staged fracturing string of an open hole packer with precise seams includes the following steps:

[0036] In the first step, the pipe string is run in. After the open hole horizontal well is drilled, the main oil pipe 8 and all the sliding sleeves 3 and packers 7 on the main oil pipe 8 are sequentially run into the casing 16 from the wellhead, and pass through the open hole wellbore 15 Go all the way down to the design position;

[0037] After the drilling is completed, the main tubing 8 and its sliding sleeve 3, packer 7 and other components are lowered to the design position of the open hole wellbore 15. Multi-stage fracturing is performed sequentially toward the wellhead. Each stage is 80-150 meters long on the said total oil pipe 8, and the sliding sleeve 3 of each stage is all positioned at the center of each stage.

[0038] In the second step, the packer 7 is set, the completion fluid is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com