Shale gas horizontal well segmented fracturing variable density cluster perforation method and perforation gun

A fission density, horizontal well technology, used in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problem of inability to use induced stress interference, difficulty in ensuring adequate stimulation and smooth sanding, and failure to consider geological sweet spots and The distribution characteristics of engineering sweet spots, etc., can improve the complexity, improve the fracturing stimulation effect, and strengthen the promotion and application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

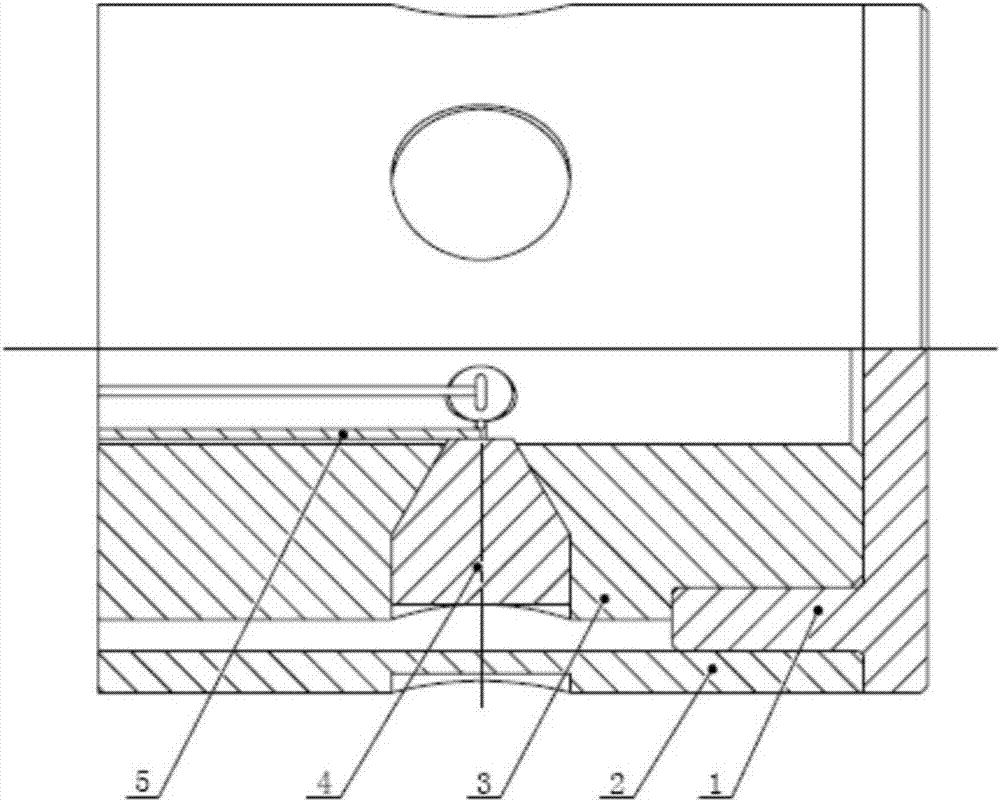

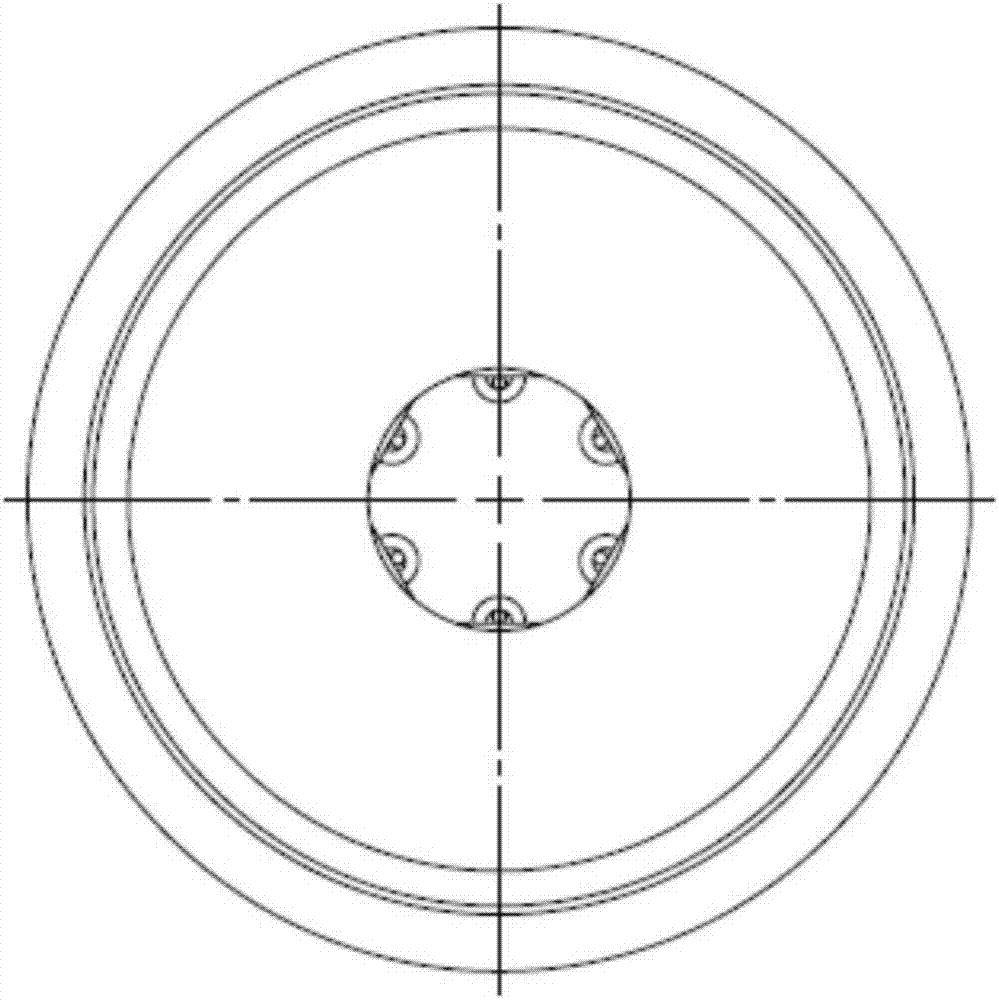

[0036] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0037] The invention provides a shale gas horizontal well staged fracturing variable density cluster perforation method and a perforating gun, which optimizes various parameters of the cluster perforation to increase the complexity of fracturing fractures and improve the fracturing stimulation effect.

[0038] The technical scheme that the present invention takes carries out according to the following steps:

[0039] (1) Optimize the perforation method, change the currently used spiral distributed perforation to circumferential perforation at a certain position along the horizontal wellbore (the perforation and fracturing position is optimized according to the double sweet spots of reservoir geology and engineering.) , so that the fractures of all perforations will enter into one fracture channel, and even if the direction of the horizontal wellbore is not consistent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com