Autoclaved aerated concrete block and production process thereof

A concrete block and autoclaved aerated technology, applied in the field of building materials, can solve the problem of poor heat insulation, heat preservation, fire resistance and sound insulation effect of blocks, disadvantageous use of autoclaved aerated concrete blocks, no energy saving and waste utilization. And environmental protection and other issues, to achieve the effect of improving the utilization rate of the building area, reducing the weight and improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

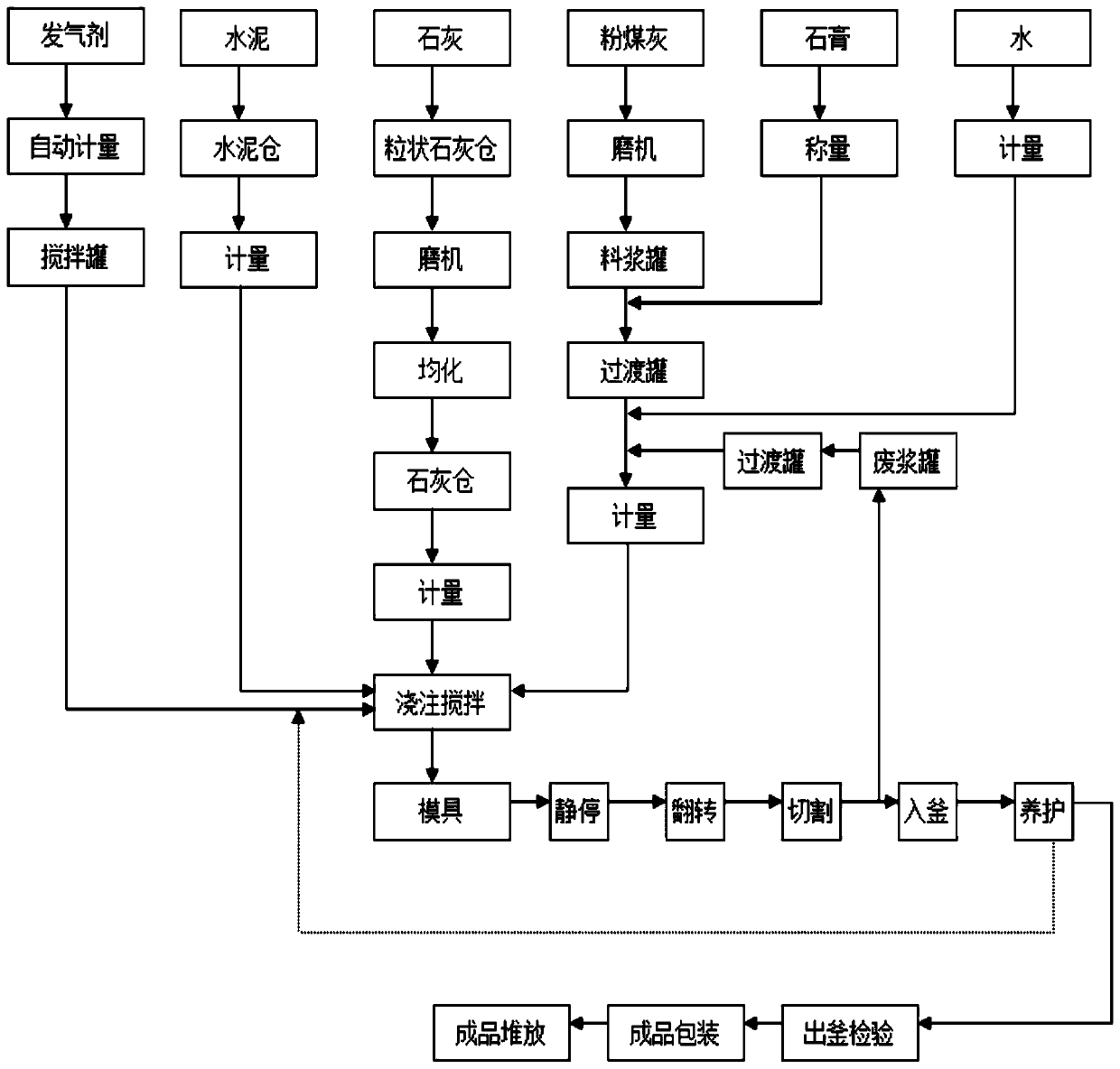

Method used

Image

Examples

Embodiment 1

[0032] An autoclaved aerated concrete block, its raw materials include by weight percentage: 32.5% of cementitious material, 50% of slurry, 2.5% of gypsum and 15% of air-generating agent, and the cementitious material is fly ash, sand and silicon-containing The composition of the tailings, the slurry is prepared by stirring and mixing lime and cement with water, and the gas-generating agent is selected from aluminum powder.

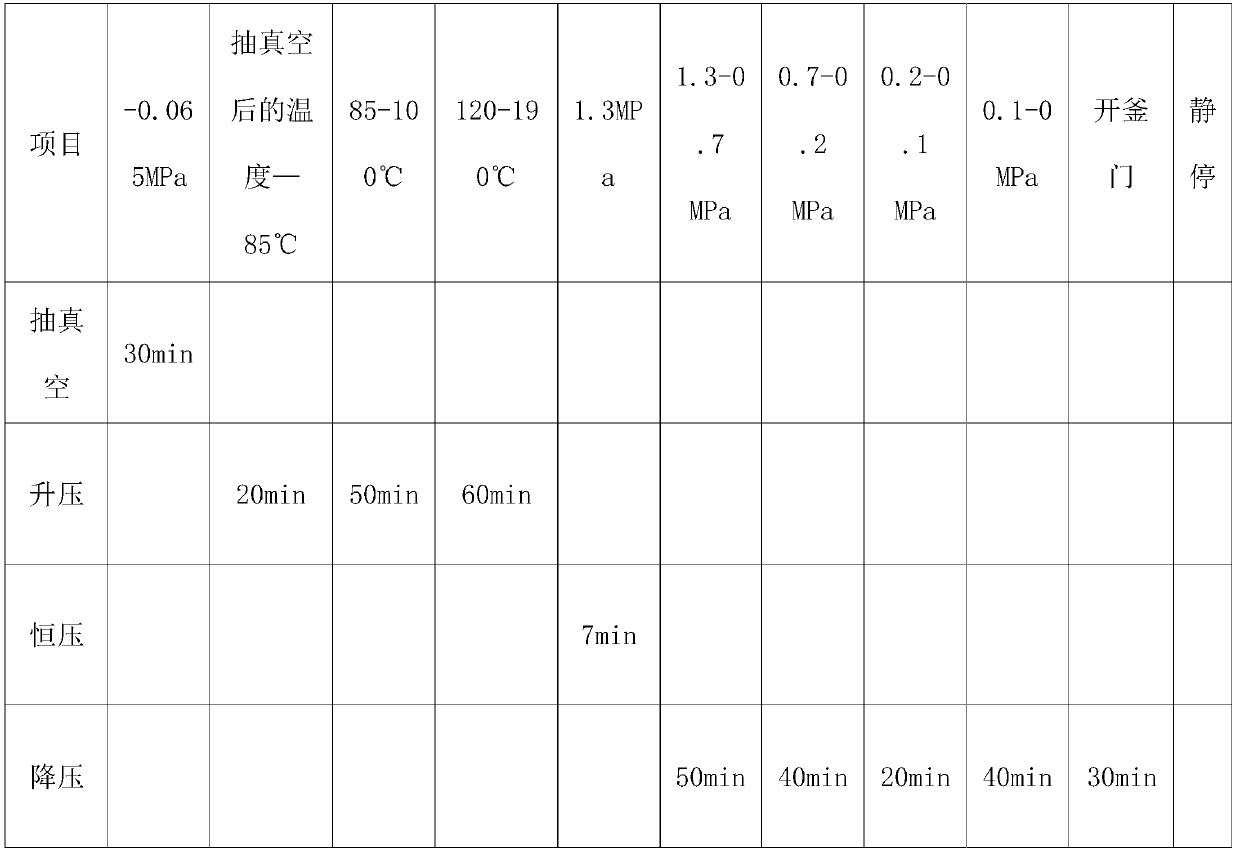

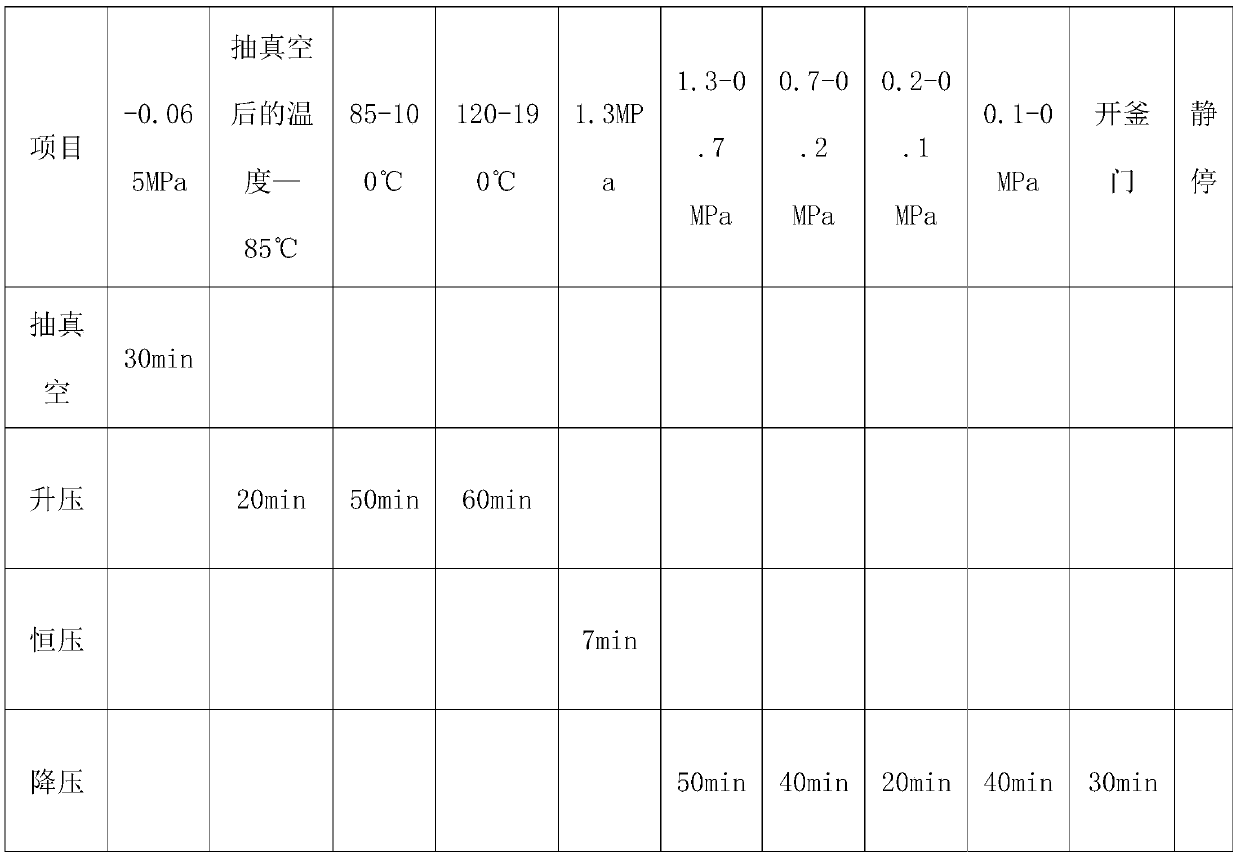

[0033] A production process of an autoclaved aerated concrete block, specifically comprising the following steps:

[0034]S1. Preparation of stone powder: first send the stone powder to the storage yard, weigh it through a belt scale, and then transport the weighed stone powder to the mill for grinding through the belt conveyor, and then transport the ground powder to the pulping In the pool, add water, perform beating treatment through the beating mechanism, and then collect through the slurry storage tank to obtain stone powder slurry;

[0035] S2. Pre...

Embodiment 2

[0044] An autoclaved aerated concrete block, its raw materials include by weight percentage: 25% of cementitious material, 70% of slurry, 1.5% of gypsum and 3.5% of gas-generating agent, the cementitious material is fly ash, and the slurry is made of It is prepared by mixing lime and cement with water, and aluminum powder is used as the gas-generating agent.

[0045] A production process of an autoclaved aerated concrete block, specifically comprising the following steps:

[0046] S1. Preparation of stone powder: first send the stone powder to the storage yard, weigh it through a belt scale, and then transport the weighed stone powder to the mill for grinding through the belt conveyor, and then transport the ground powder to the pulping In the pool, add water, perform beating treatment through the beating mechanism, and then collect through the slurry storage tank to obtain stone powder slurry;

[0047] S2. Preparation of mixed ash: The lime is sent to the lime stockyard, and...

Embodiment 3

[0056] An autoclaved aerated concrete block, the raw materials of which include by weight percentage: 40% of cementitious material, 55% of slurry, 3.5% of gypsum and 1.5% of air-generating agent, the cementitious material is silicon-containing tailings, and the slurry is It is made by stirring and mixing lime and cement with water, and aluminum powder is used as the gas-generating agent.

[0057] A production process of an autoclaved aerated concrete block, specifically comprising the following steps:

[0058] S1. Preparation of stone powder: first send the stone powder to the storage yard, weigh it through a belt scale, and then transport the weighed stone powder to the mill for grinding through the belt conveyor, and then transport the ground powder to the pulping In the pool, add water, perform beating treatment through the beating mechanism, and then collect through the slurry storage tank to obtain stone powder slurry;

[0059] S2. Preparation of mixed ash: The lime is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com