Process for dehydrating hydrocarbon-based gas

一种烃基气体、气体的技术,应用在分离方法、气体燃料、气体处理等方向,能够解决液体干燥剂损失、降低液体干燥剂气体脱水的能力等问题,达到易于实施的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

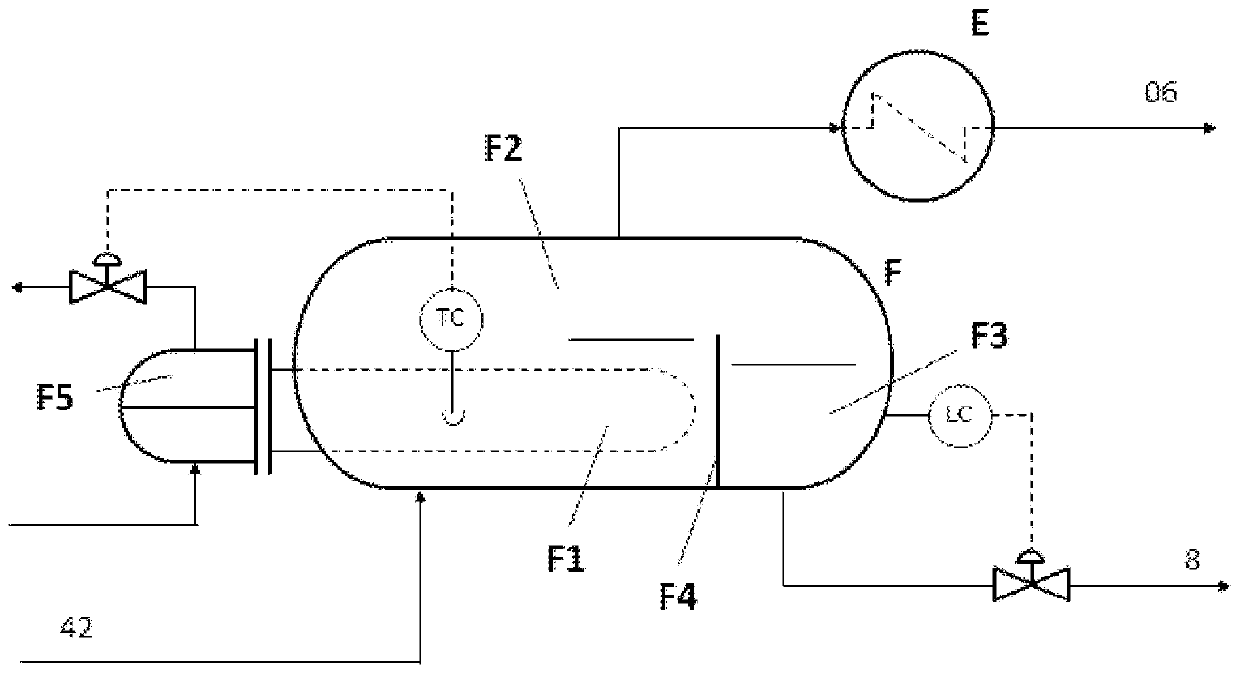

[0091] refer to figure 1 An example of operation of the method of the present invention is described.

[0092] Considering the crude natural gas at saturation, 340 t / h of gas are produced, the composition of which is described in Table 1, line 12.

[0093] The gas is produced at a pressure of 75 bar g and a temperature of 35°C. The gas is saturated with water at a content of 0.1 mol%, which delivers a water flow of 330 kg / h.

[0094] After passing the crude natural gas through the drying unit 20, a dry gas is obtained with a water composition of less than 1 mole ppm, ie a flow rate of less than 0.3 kg / h, the composition of which is described in Table 1, line 21.

[0095] The desiccant liquid was triethylene glycol with a water-TEG binary purity of 99.99% by weight TEG and 0.01% by weight water.

[0096] The column for contacting the desiccant liquid with the wet gas in unit 20 operates substantially at the inlet conditions of the gas to be treated.

[0097] Unit 30 operate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com