Water-based ink-jet ink composition, method for suppressing fading of printed images on solid formulations, and solid formulation

A technology of water-based ink and solid preparation, applied in the direction of copying/marking method, printing, ink, etc., can solve the problem of chroma reduction and achieve the effect of improving light resistance and reducing fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

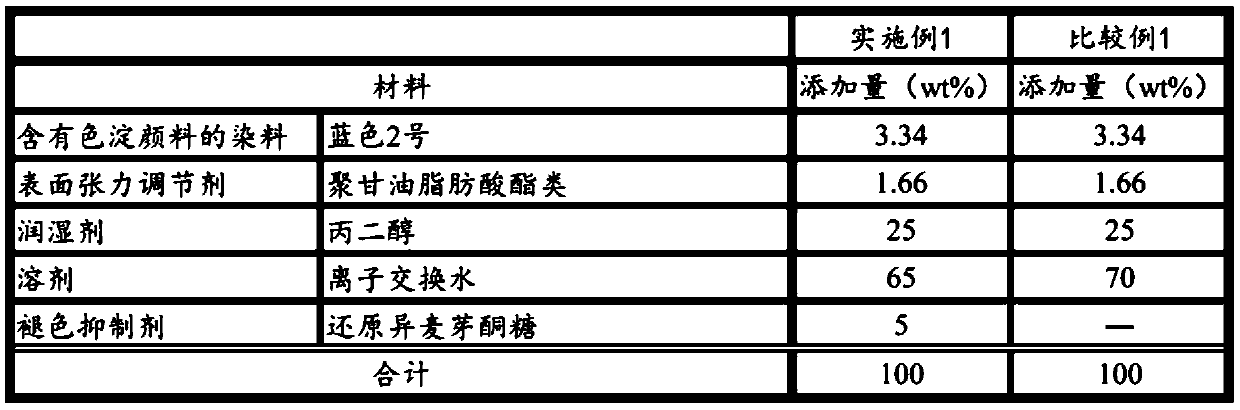

[0087] As shown in the following Table 1, 3.34% by mass of a lake pigment containing Blue No. 2 (dye) as a specific lake pigment (trade name: Blue No. 2 Aluminum Lake, manufactured by Daiwa Kasei Co., Ltd.), 5 mass % 5% by mass of reduced isomaltulose (trade name: Palatinit, manufactured by Mitsui Sugar Co., Ltd.) as a fading inhibitor, 1.66% by mass of polyglycerol fatty acid esters (trade name: SY GLYSTAR, manufactured by Sakamoto Pharmaceutical Co., Ltd.), 25% by mass of propylene glycol as a wetting agent, and 65% by mass of ion-exchanged water were mixed to prepare a blue inkjet aqueous ink composition.

[0088] [Table 1]

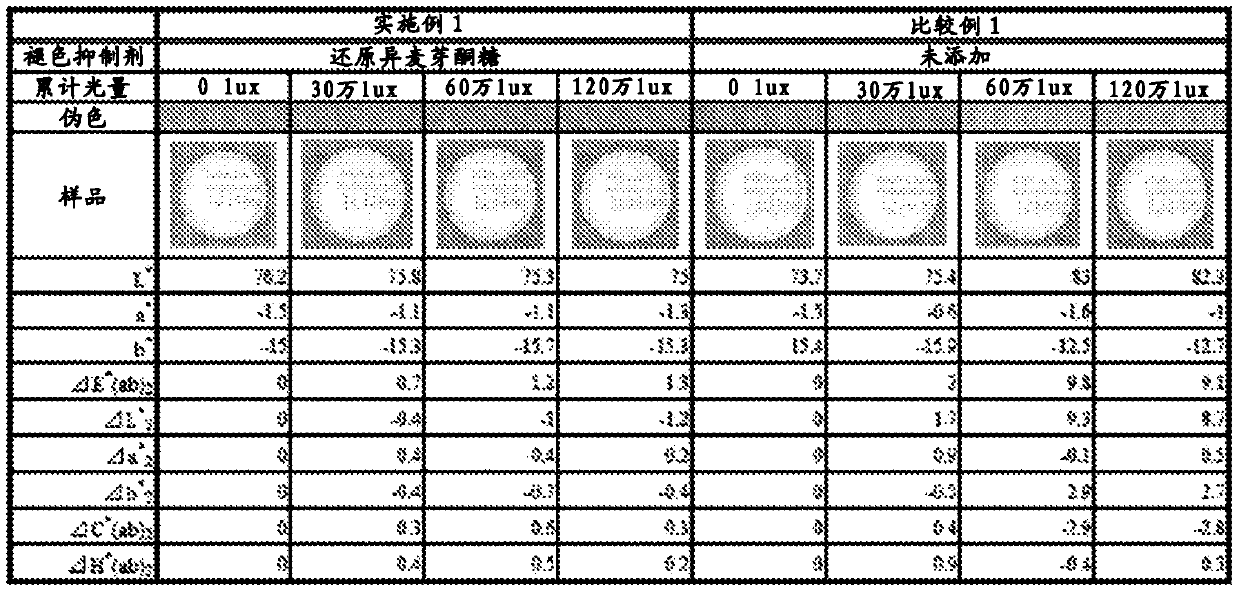

[0089]

[0090] Using the aqueous ink composition of this example, printing was performed on one side of the FC sheet by an inkjet recording method. Printing was performed by a multi-pass method using an inkjet printer (PX-105, manufactured by Seiko Epson Co., Ltd.). In addition, printing was performed in the environment of 25 degreeC of air tempe...

Embodiment 2

[0109] As shown in Table 3, 8% by mass of a lake pigment containing Yellow No. 4 (dye) as a specific lake pigment (trade name: Yellow No. 4 Aluminum Lake, manufactured by Daiwa Kasei Co., Ltd.), 1% by mass as a pigment Sodium polyacrylate as a dispersant (trade name: TEGO (registered trademark) Dispers 715W, manufactured by Evonik, mass average molecular weight: 3000), 1% by mass of disodium malate (manufactured by Wako Pure Chemical Industries, Ltd.) as a dispersion stabilizer, and 50% by mass of ion-exchanged water as a dispersion medium was mixed in a container, and the mixed liquid was dispersed with a disperser (paint shaker, manufactured by Asada Iron Works Co., Ltd.) to prepare a dispersion liquid of a specific lake pigment. Next, 12% by mass of reduced isomaltulose (trade name: Palatinit, manufactured by Mitsui Sugar Co., Ltd.) as a fading inhibitor and 15% by mass of isomaltulose as a wetting agent were added to the prepared specific lake pigment dispersion. Propylene...

Embodiment 3

[0111] As shown in Table 3, it was the same as that of Example 2 except that the discoloration inhibitor was changed to galactose (manufactured by Wako Pure Chemical Industries, Ltd.).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com