Transformer substation monitoring method

A substation monitoring and substation technology, applied in the field of substation monitoring, can solve problems such as omission, dangerous high-voltage equipment, and lack of protection functions, etc., to achieve strong practicability, ensure safe operation, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

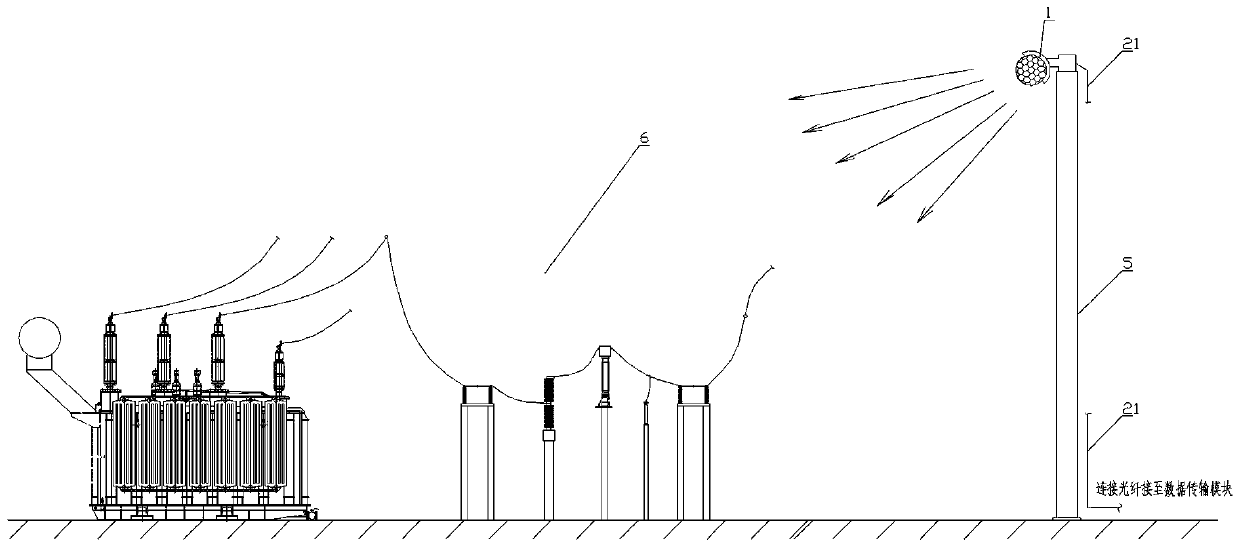

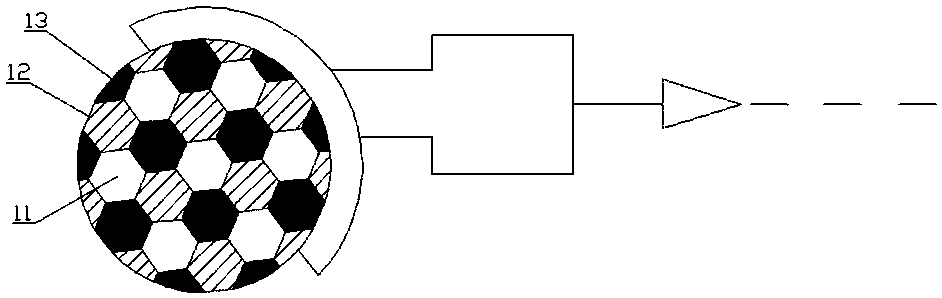

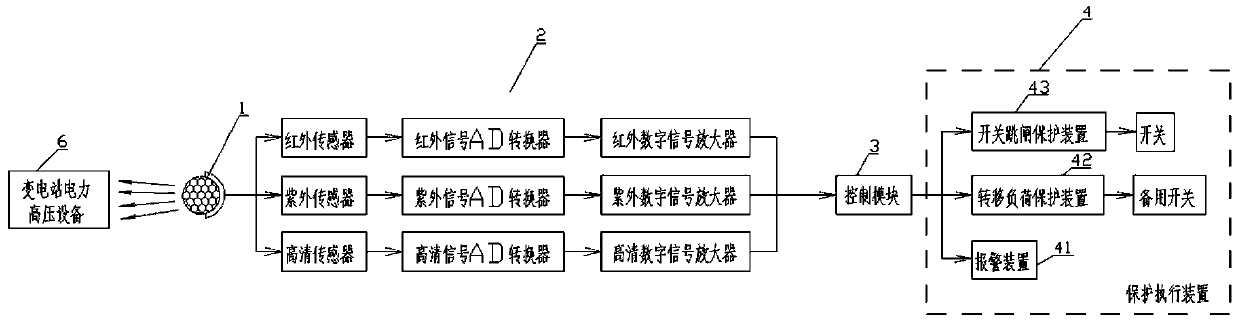

[0019] The present invention provides a substation monitoring method aiming at the operation mode and its own characteristics of the electric high-voltage equipment in the substation, such as Figure 1~3 As shown, a compound eye combination probe 1 composed of multiple miniature infrared probes 11, miniature ultraviolet probes 12 and miniature high-definition probes 13 is installed on the monitoring pole in the substation to monitor each electric high-voltage equipment 6 in the substation. The probes detect overheating faults in the operation of high-voltage electric equipment. The probes are arranged on the compound eye combination probe according to the regular hexagonal interval of the bionic compound eye. The discharge fault of the high-voltage electric equipment is detected by the miniature ultraviolet probe, and the opening and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com