Texturing liquid for texturing polycrystalline silicon wafer and texturing method using texturing liquid

A polycrystalline silicon wafer and texturing liquid technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve the problem of large amount of reflectance chemicals, small openings on the textured surface of silicon wafers, and uniform textured surface To achieve the effects of production line compatibility, reduce reflectivity, and improve conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

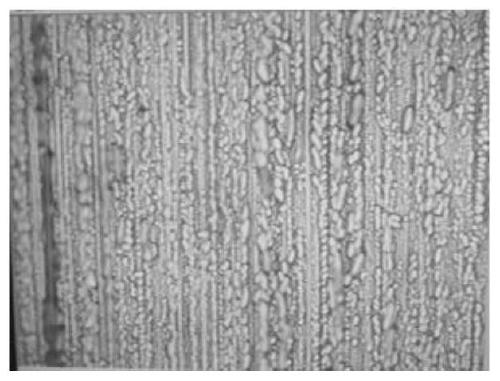

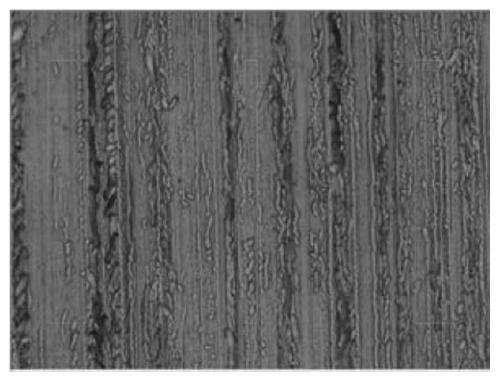

Image

Examples

Embodiment 1

[0033] A method for making texture of a polycrystalline silicon wafer, comprising the following steps:

[0034] Prepare velvet solution:

[0035] HNO 3 55kg, HF17kg, additive 0.7kg, water 27.3kg;

[0036] Raw material composition of additives: CH 3 COOH0.14kg, H 3 PO 4 0.14kg, H 2 SO 4 0.14kg, water 0.28kg.

[0037] Put the polycrystalline silicon wafer in the texturing solution for reaction, the reaction temperature is 12°C, the reaction time is 60s, and the amount of texturing corrosion is controlled to be 0.24-0.26g / pcs;

[0038] (2) After water washing, alkali washing, water washing, pickling, water washing, and drying, the cashmere-making process is completed.

Embodiment 2

[0040] A method for making texture of a polycrystalline silicon wafer, comprising the following steps:

[0041] Prepare velvet solution:

[0042] HNO 3 52kg, HF15kg, additive 0.6kg, water 32.4kg;

[0043] Raw material composition of additives: CH 3 COOH0.06kg, H 3 PO 4 0.06kg, H 2 SO 4 0.06kg, water 0.42kg.

[0044] Put the polycrystalline silicon wafer in the texturing solution for reaction, the reaction temperature is 10°C, the reaction time is 40s, and the amount of texturing corrosion is controlled to be 0.24-0.26g / pcs;

[0045] (2) After water washing, alkali washing, water washing, pickling, water washing, and drying, the cashmere-making process is completed.

Embodiment 3

[0047] A method for making texture of a polycrystalline silicon wafer, comprising the following steps:

[0048] Prepare velvet solution:

[0049] HNO 3 50kg, HF12kg, additive 0.5kg, water 37.5kg;

[0050] Raw material composition of additives: CH 3 COOH0.005kg, H 3 PO 4 0.005kg, H 2 SO 4 0.005kg, water 0.49985kg.

[0051] Put the polysilicon wafer in the texturing solution for reaction, the reaction temperature is 8°C, the reaction time is 30s, and the texturing corrosion amount is controlled to be 0.24-0.26g / pcs;

[0052] (2) After water washing, alkali washing, water washing, pickling, water washing, and drying, the cashmere-making process is completed.

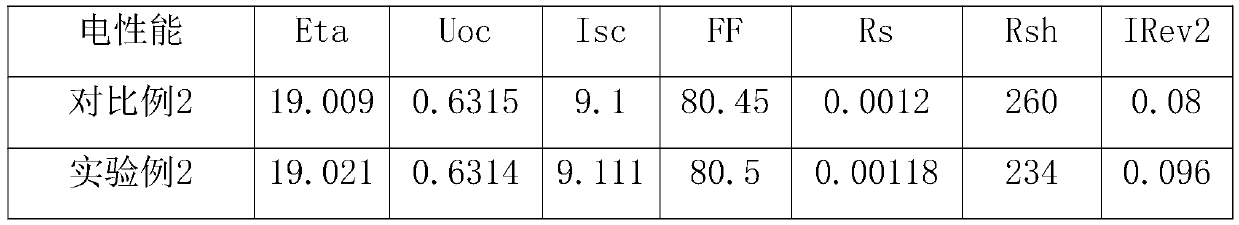

[0053] Effect experiment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com