ABAQUS-based honeycomb composite material ultrasonic cutting process simulation method

A technology of ultrasonic cutting and honeycomb materials, which is applied in the fields of ships, automobiles, and aerospace, and can solve the problems of high cost and the inability to present microscopic damaged surfaces of characteristic materials at the contact interface of tools and materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

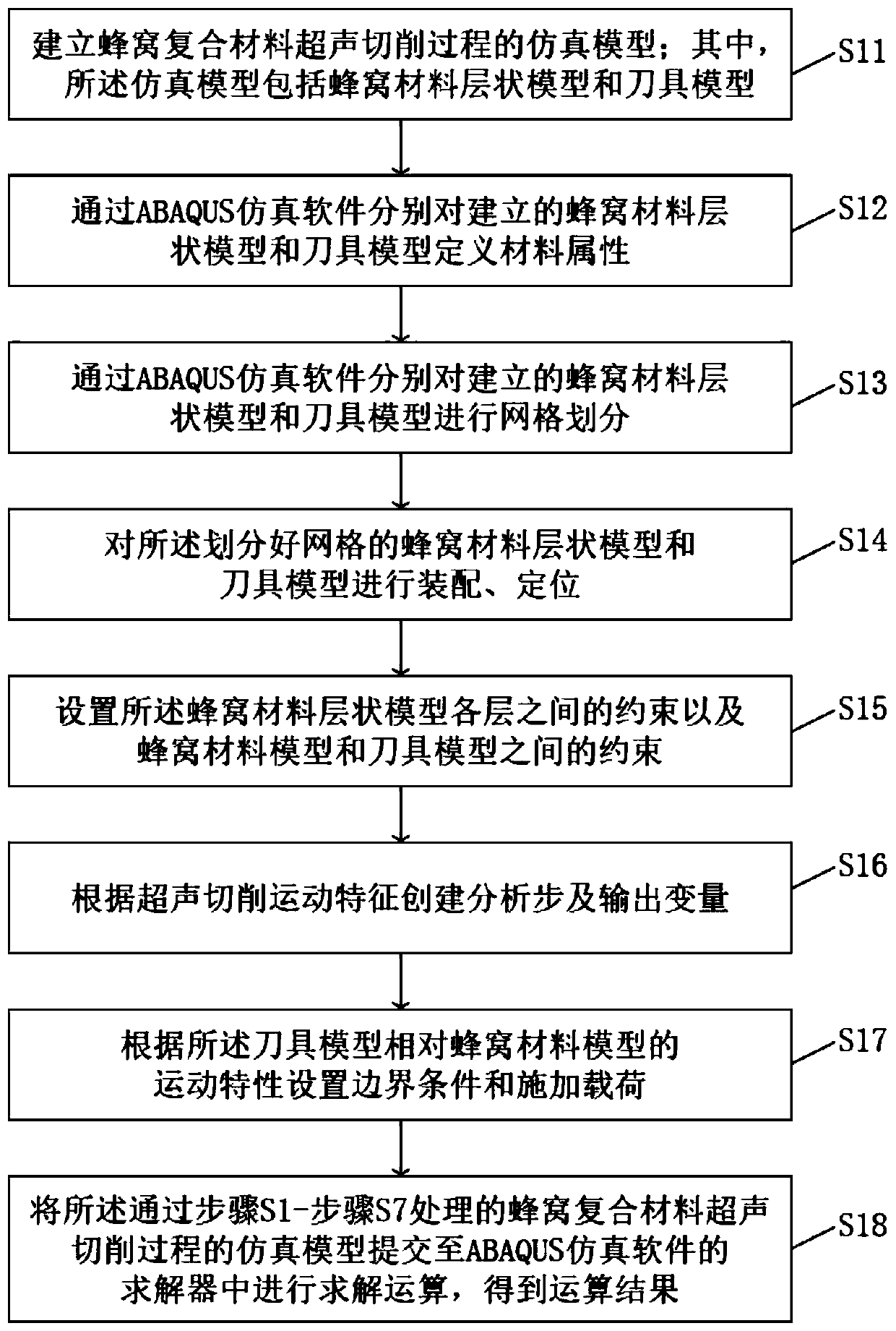

[0037] This embodiment one provides a kind of ABAQUS-based honeycomb composite material ultrasonic cutting process simulation method, such as Figure 1-5 shown, including steps:

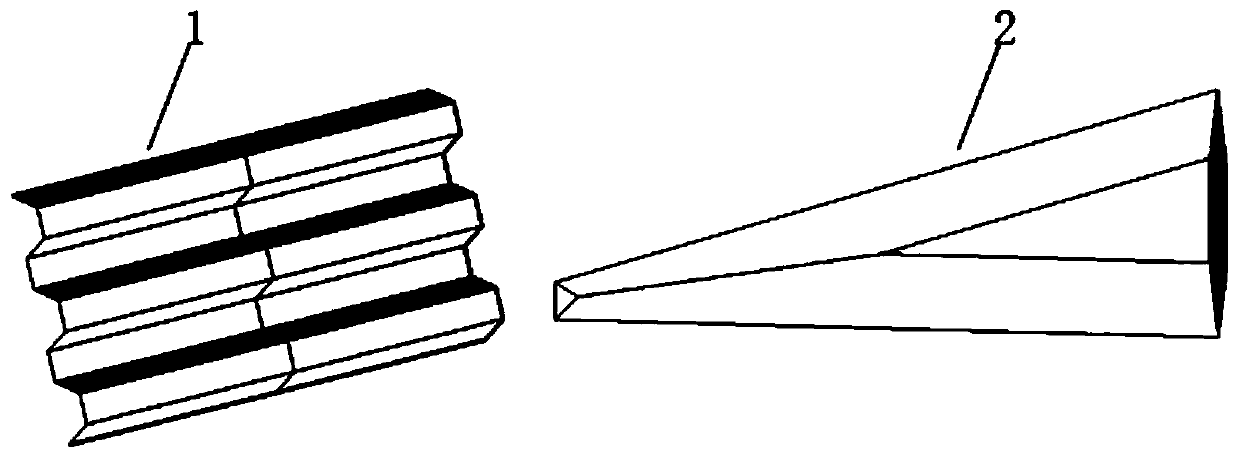

[0038] S11. Establish a simulation model of the honeycomb composite material ultrasonic cutting process; wherein, the simulation model includes a honeycomb material layered model and a tool model;

[0039] S12. Define the material properties of the honeycomb material layered model and the cutter model respectively by ABAQUS simulation software;

[0040] S13. Mesh the honeycomb material layered model and tool model established by ABAQUS simulation software;

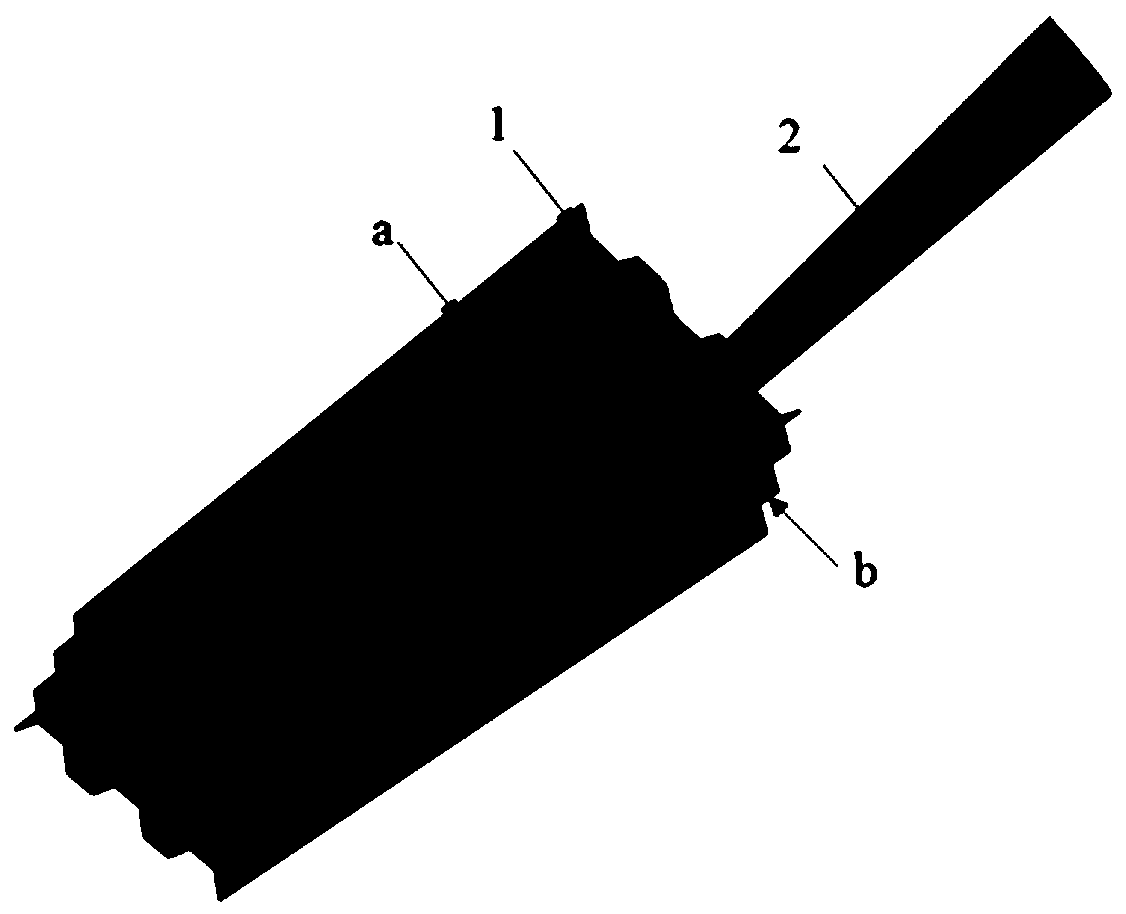

[0041] S14. Assembling and positioning the meshed honeycomb material layered model and tool model;

[0042] S15. Set the constraints between the layers of the honeycomb material layered model and the constraints between the honeycomb material model and the tool model;

[0043] S16. Create analysis steps and output variables according to the ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com