A Downward Approach Filling Mining Method

A mining method and access filling technology, applied in underground mining, filling, surface mining, etc., can solve the problems of lack of support, potential safety hazards, and low mining efficiency, so as to improve mining efficiency, reduce filling costs, and improve mining efficiency. The effect of mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

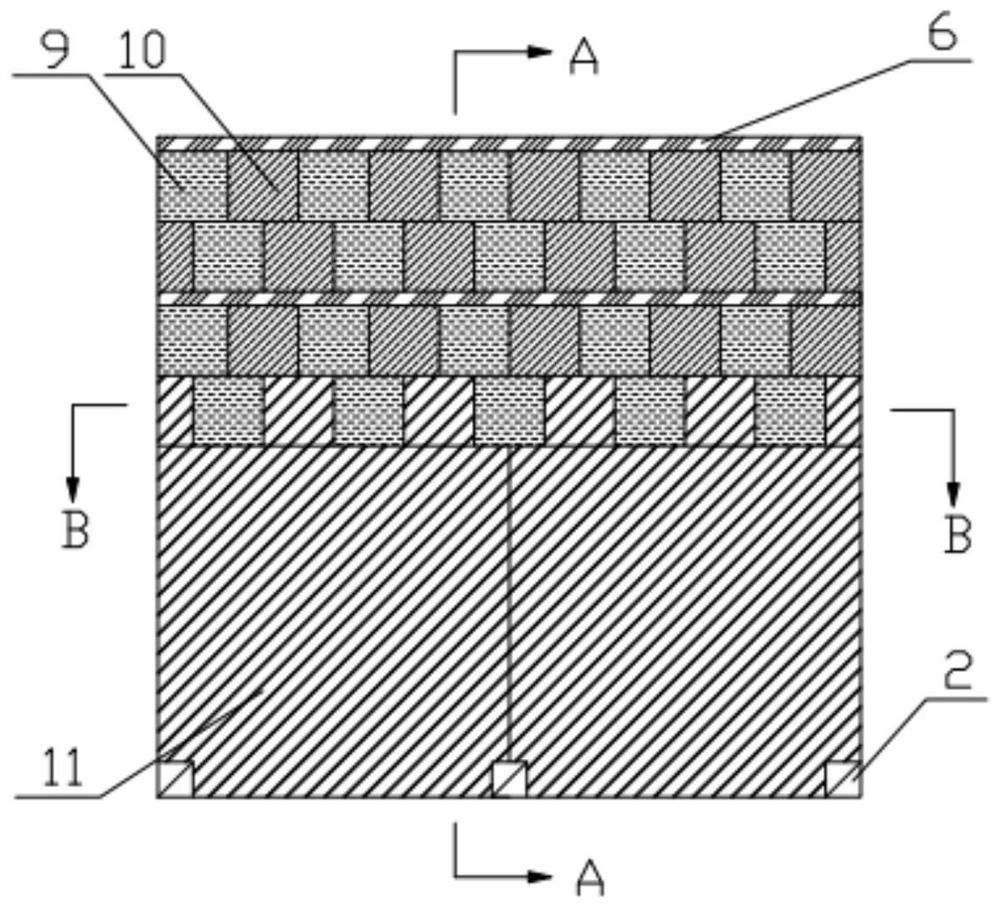

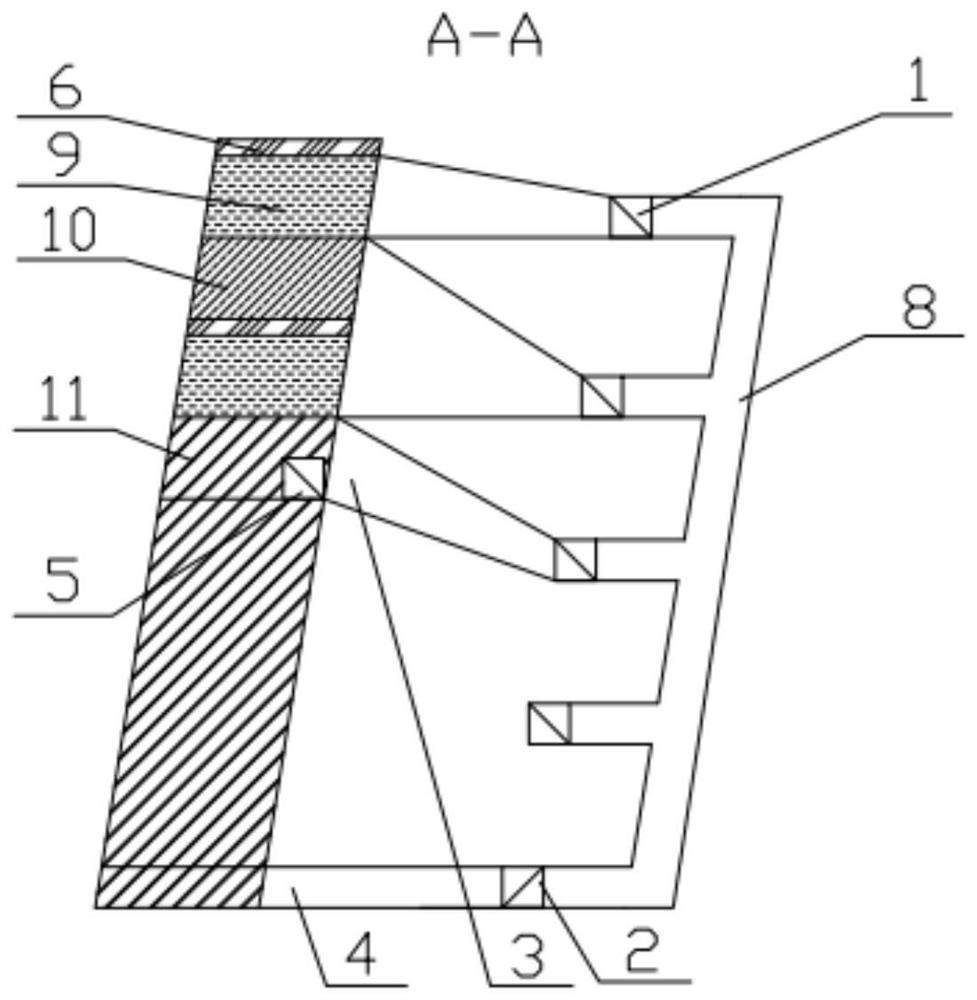

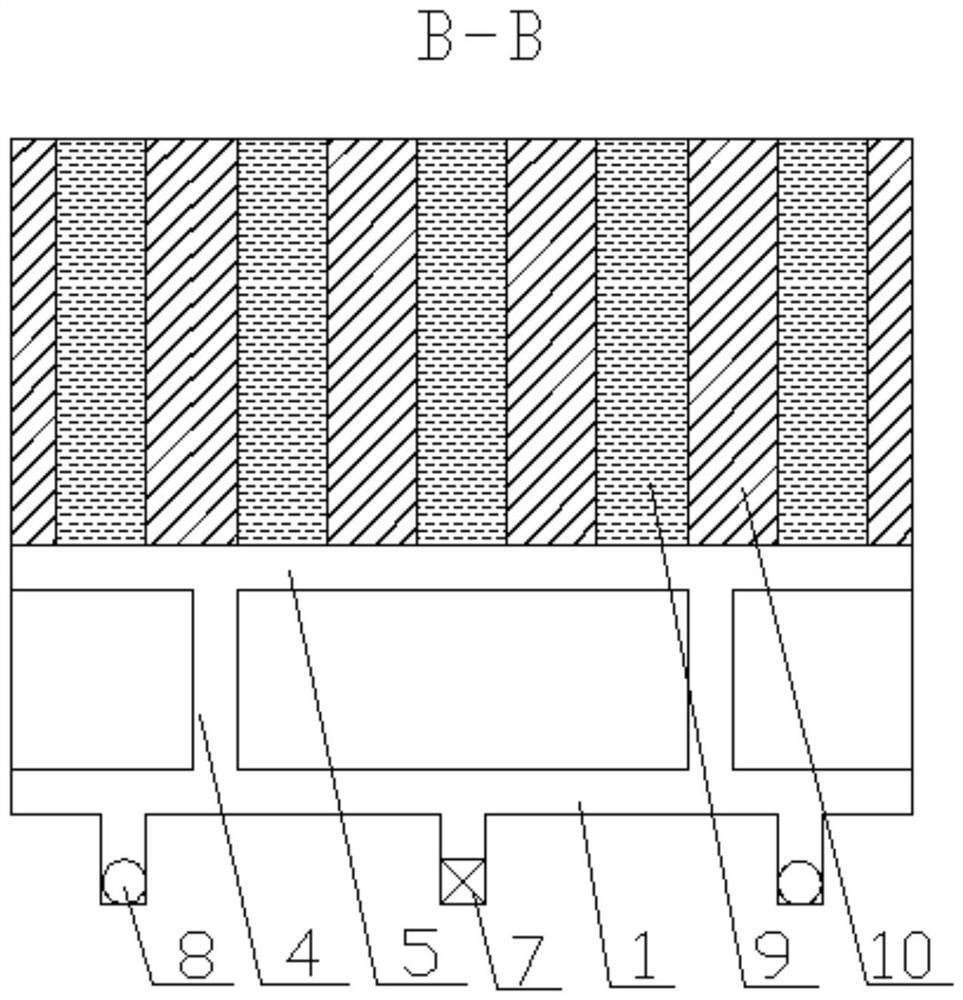

[0033] see figure 1 , the present embodiment provides a downward approach filling mining method, the selected ore body is a steeply inclined ore body with unstable ore rocks, and the downward approach filling mining method includes the following steps:

[0034] S1. Block division

[0035] The height of the middle section of mining is 40m, and the middle section of mining is divided into four subsections on average, and each section is 10m high; Each layer is divided into several ore blocks on average, and the width and layer height of each ore block are equal, and the ore blocks between adjacent layers are staggered by half the width of the ore block.

[0036] S2. Accurate layout

[0037]The mining middle section is arranged by mining outside the vein, and a section transportation lane 1 is arranged every 10m, and a middle section transportation lane 2 is arranged at the bottom of the mining middle section, and the section transportation lane 1 and the middle section transpo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com